5installation – Burkert Type 5282 User Manual

Page 3

5

4.2 Application conditions

Ambient temperature:

max. +55 °C

Permitted medium temperature and permitted media depending on seal

material:

Seal

material

Medium

temperature

Permitted media

FKM

0 °C ... +90 °C

Per-solutions, hot oils without additives,

diesel and heating oil without additives,

detergent solution

EPDM

-30 °C ... +90 °C Oil and grease-free liquids,

cold and hot water

NBR

0 °C ... +80 °C

Cold and warm water

Operating duration

Unless otherwise indicated on the type label, the solenoid system is suitable

for continuous operation.

Important information for functional reliability during conti-

nuous operation: If standstill for a long period at least 1-2 acti-

vations per day are recommended.

Service life

High switching frequency and high pressures reduce the service life.

4.3 Conformity

Type 5282 conforms with the EC Directives according to the EC Decla-

ration of Conformity.

4.4 Standards

The applied standards, which verify conformity with the EC Directives,

can be found on the EC-Type Examination Certificate and / or the EC

Declaration of Conformity.

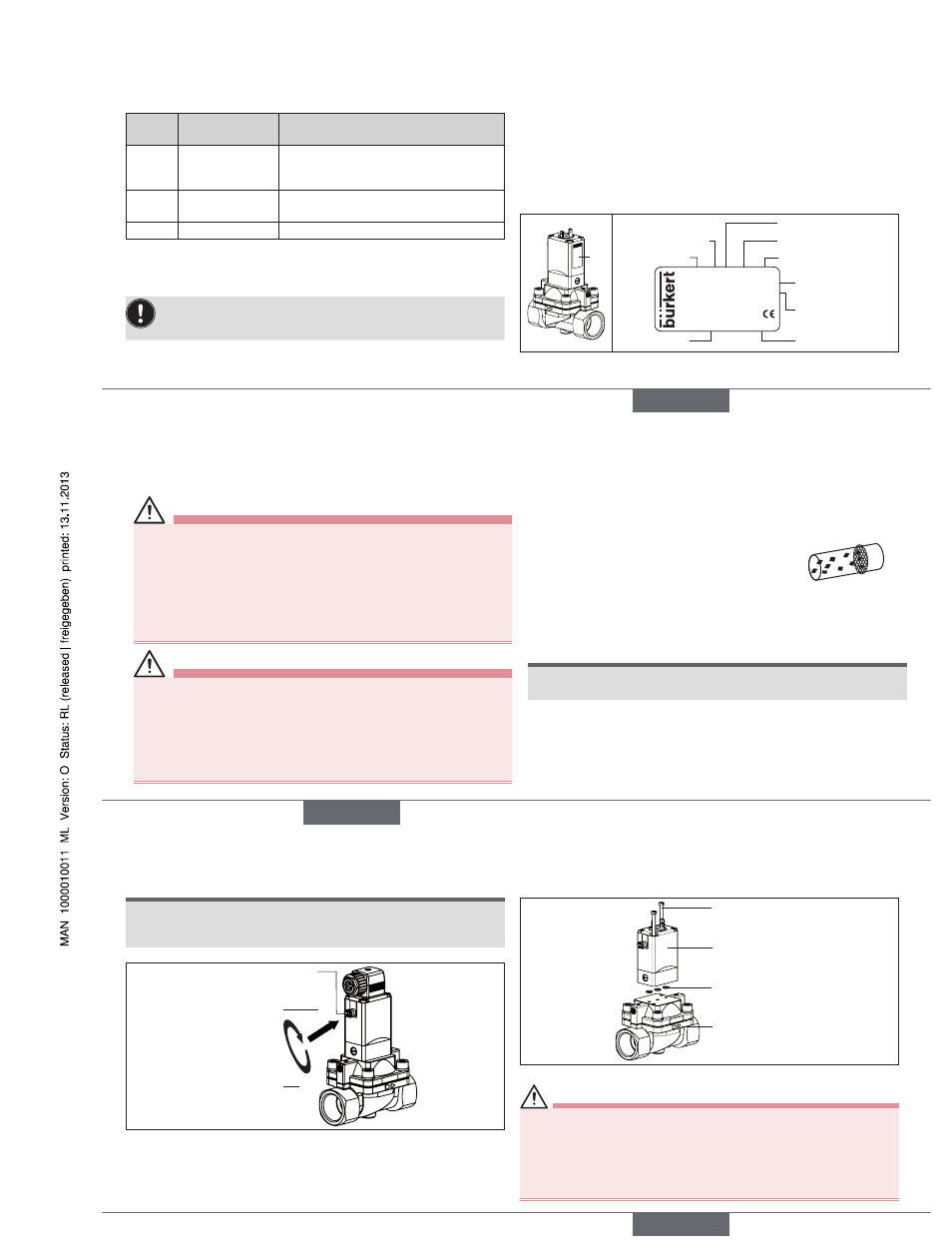

4.5 Type label

Type label

Type

Operating prinziple

Orifice

Seal material

Body material

Id. Number

Manufacturer-Code

Voltage, frequency,

power consumption

Connection thread,

pressure range

Example:

5282 A 25 EPDM MS

Made in Germany

00134469

W17 LU

230V 50-60Hz 8W

G1 1/4 P

N 0,2

-

16 bar

Fig. 1:

Location and inscription of the type label

english

6

5

INSTALLATION

5.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the pipes and valves, turn off the pressure and vent

the pipes.

Risk of injury due to electrical shock!

▶ Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

▶ Observe applicable accident prevention and safety regulations for

electrical equipment!

WARNING!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

5.2 Before installation

Installation position:

Installation can be in any position.

Preferably: Actuator upright.

→

Prior to installation check pipelines for dirt and, if required, clean.

Dirt filter: To ensure that the solenoid valve

functions reliably, a dirt filter (

≤ 500 µm) must be

installed in front of the valve inlet.

5.3 Installation

→

Hold the device with a suitable tool (open-end wrench) on the body

and screw into the pipeline.

NOTE!

Caution risk of breakage!

• Do not use the coil as a lever arm.

→

Observe direction of flow:

The arrow on the body indicates the direction of flow (no function in

opposite flow direction).

english

7

5.4 Manual emergency actuation

NOTE!

Caution!

• When the manual emergency actuation is locked, the valve can no

longer be actuated electrically.

1

2

Press

Turn

Manual emergency

actuation

Fig. 2:

Manual emergency actuation

5.5 Changing valve function

(not possible for var Code CF02 and MT50)

max. 2.0 Nm

Pilot valve

O-rings

Identification for

the flow direction

Fig. 3:

Installing the pilot valve (changing valve function)

DANGER!

Discharge of medium due to leaking device!

If the O-rings are forgotten or incorrectly inserted during installation

of the pilot valve, the device will be damaged and medium will be

discharged.

• Before screwing in the pilot valve, correctly insert O-rings into the

depressions.

english

Type 5282