English – Burkert Type 2712 User Manual

Page 10

8 - 2712 big

C

OMMISSIONING

english

Procedure:

1. Remove the electrical and pneumatic supplies from the

Top

Control.

2. Pull off the pneumatic hose between Top

Control and actuator

at the control port of the latter.

3.

Control function A:

Pressurize the lower control port of the actuator with

compressed air (6 bar), so that the control cone is lifted from

the valve seat and is not damaged.

Control function B:

With control function B, no compressed air must be applied

for this purpose.

4. Remove the actuator in the open valve position by

unscrewing the threaded nipple (SW70) from the housing.

Installation of the valve

NOTE

For applications in aggressive media, we recommaend attaching all free pneumatic

connections to a pneumatic hose whose other end lies in a neutral atmosphere.

DN

65

80

100

Tightening torque

[Nm]

100 ± 5

120 ± 5

150 ± 5

Tightening torques for the threaded nipple (SW70)

ATTENTION!

Do

not loosen the screw (SW65) above the

threaded nipple!

screw

(SW65)

threaded nipple

(SW70)

5. Before reinstalling the actuator (in the open valve position), grease the nipple thread with

stainless steel lubricant, e.g. Klüberpaste UH1 96-402 from Messrs. Klüber and replace

the graphite seal.

6. After tightening the threaded nipple (observe torque), the actuator can be aligned as required.

For this purpose, unscrew the screw (SW65) above the threaded nipple ca. a half-turn and bring the

actuator into the desired position.

Then retighten the screw with a torque of 100 ± 5 Nm.

ATTENTION!

For special applications such as for oxygen and analysis, use only the approved

lubricants.

Installation in any orientation, but preferably with the actuator above.

Observe the direction of flow: with control valves the general rule is: inlet under seat!

Clean piping from contamination!

Before attaching the valve housing, make sure the piping is aligned!

If the housing is to be welded on, make absolutely sure that the drive unit is removed beforehand.

ATTENTION!

During this operation, the valve must also be in the open position.

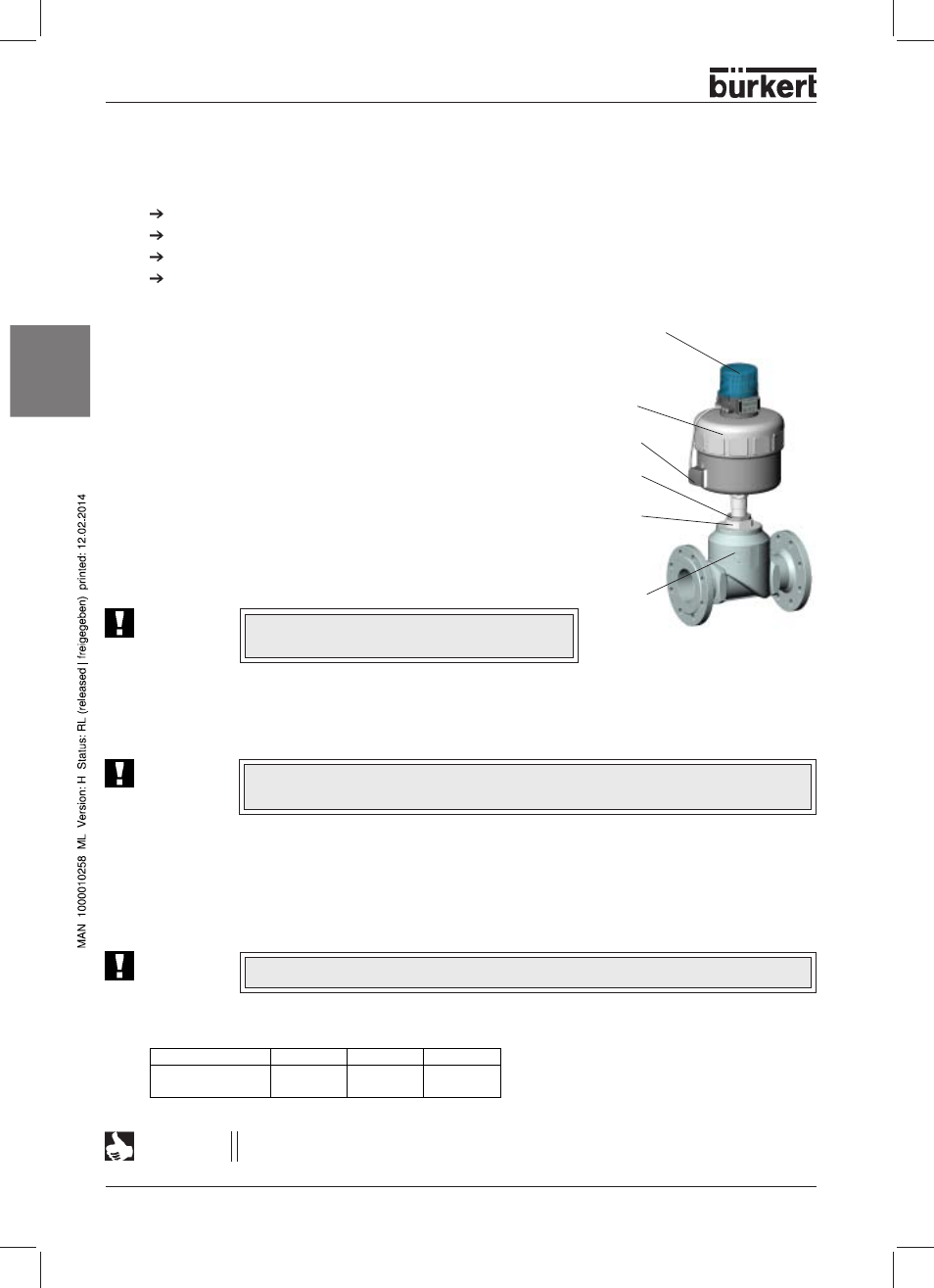

Top

Control

actuator

housing

lower

control port