Burkert Type 2000 User Manual

Page 9

9

Assembly

→

Lubricate the nipple thread before reinstalling the actuator

(e.g. with Klüberpaste UH1 96-402 produced by Klüber).

Graphite seal

note!

damage to the seat seal or the seat contour!

→

Open the valve for control functions A and I: Pressurize the

lower pilot air port with compressed air (5 bar).

→

Observe the tightening torque when screwing the actuator into

the valve body (see table).

orifice (dn)

15

20

25

32-40

50-65

tightening

torque ± 3 [nm]

45

50

60

65

70

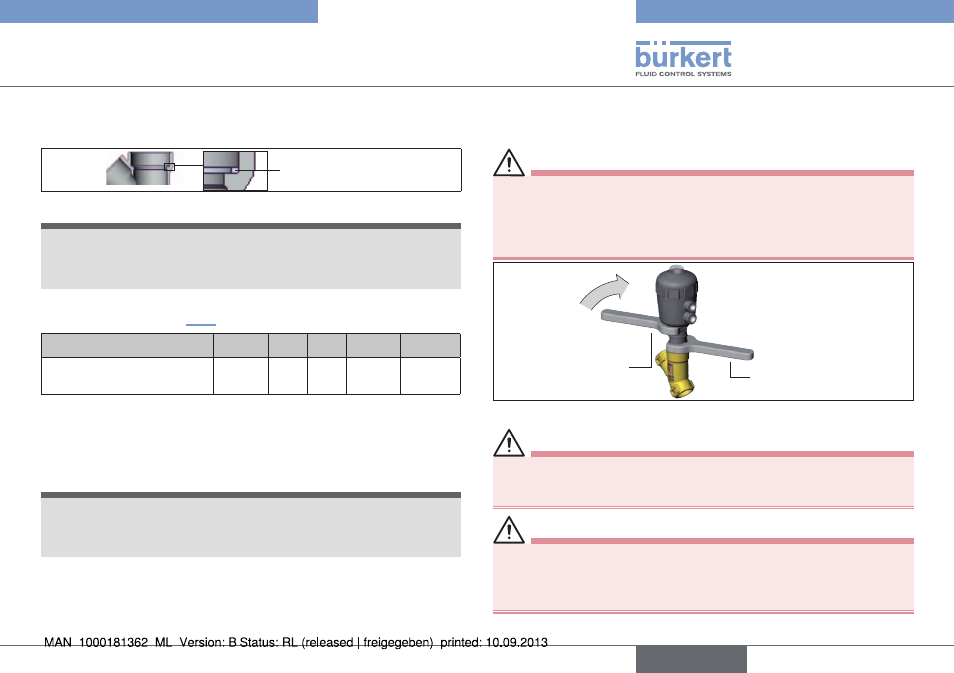

7.2. rotating the actuator

The actuator can be rotated infinitely by 360°.

→

Clamp the valve body into a holding fixture (if necessary).

note!

damage to the seat seal or the seat contour!

→

Open the valve for control functions A and I: Pressurize the

lower pilot air port with compressed air (5 bar).

→

Using a suitable open-end wrench, counter the wrench flat on

the nipple.

→

Place a suitable open-end wrench on the hexagonal bolt of the

actuator.

Warning!

risk of injury from discharge of medium and release of

pressure!

If the direction of rotation is wrong, the body interface may become

detached.

→

Turn the actuator in a clockwise direction (as seen from above).

Open-end wrench

for securing the

nipple

Open-end

wrench for

rotating the

actuator

7.3. connecting the control medium

Danger!

risk of injury from high pressure in the system!

• Turn off the pressure and vent the lines before loosening lines or

valves.

Warning!

risk of injury from unsuitable hoses!

• Use only hoses which are authorized for the indicated pressure

and temperature range.

• Observe the data sheet specifications from the hose manufacturers.

english

Type 2000