Burkert Type 0654 User Manual

Page 3

7

4

SYSTEM DESCRIPTION

4.1 General description

• Type 64.- / 65.- is used for the blocking, dosing, filling and venting of

neutral gaseous and liquid media.

• The valve can be installed individually or in a block on the multiple

manifold (follow the temperature ranges in the ATEX instructions).

5

TECHNICAL DATA

5.1 Conformity

In accordance with the EC Declaration of conformity, Type 64.- / 65.- is

compliant with the EC Directives.

5.2 Standards

The applied standards, which verify conformity with the EC Directives,

can be found on the EC-Type Examination Certificate and / or the EC

Declaration of Conformity.

5.3 Operating conditions

WARNING!

Heat sources and temperature fluctuations may cause malfunc-

tions or leaks!

▶ If the device is used outdoors, do not expose it unprotected to the

weather conditions.

▶ Avoid heat sources which may cause the allowable temperature

range to be exceeded.

5.3.1 Permitted temperature

Ambient temperature:

see instruction ATEX

Permitted medium temperature:

Circuit

function

Sealing

material

Medium

temperature

Type /

Types of installation

A

FKM / NBR

-10 ... +60 °C

64.- Single mounting

-10 ... +45 °C

64.- Block assembly

-10 ... +50 °C

65.- Single mounting

-10 ... +40 °C

65.- Block assembly

english

8

5.3.2 Permitted media

Media

neutral gaseous and liquid media, which do not

attack body and sealing materials (see table of

resistance under

www.burkert.com

)

Check resistance in individual cases

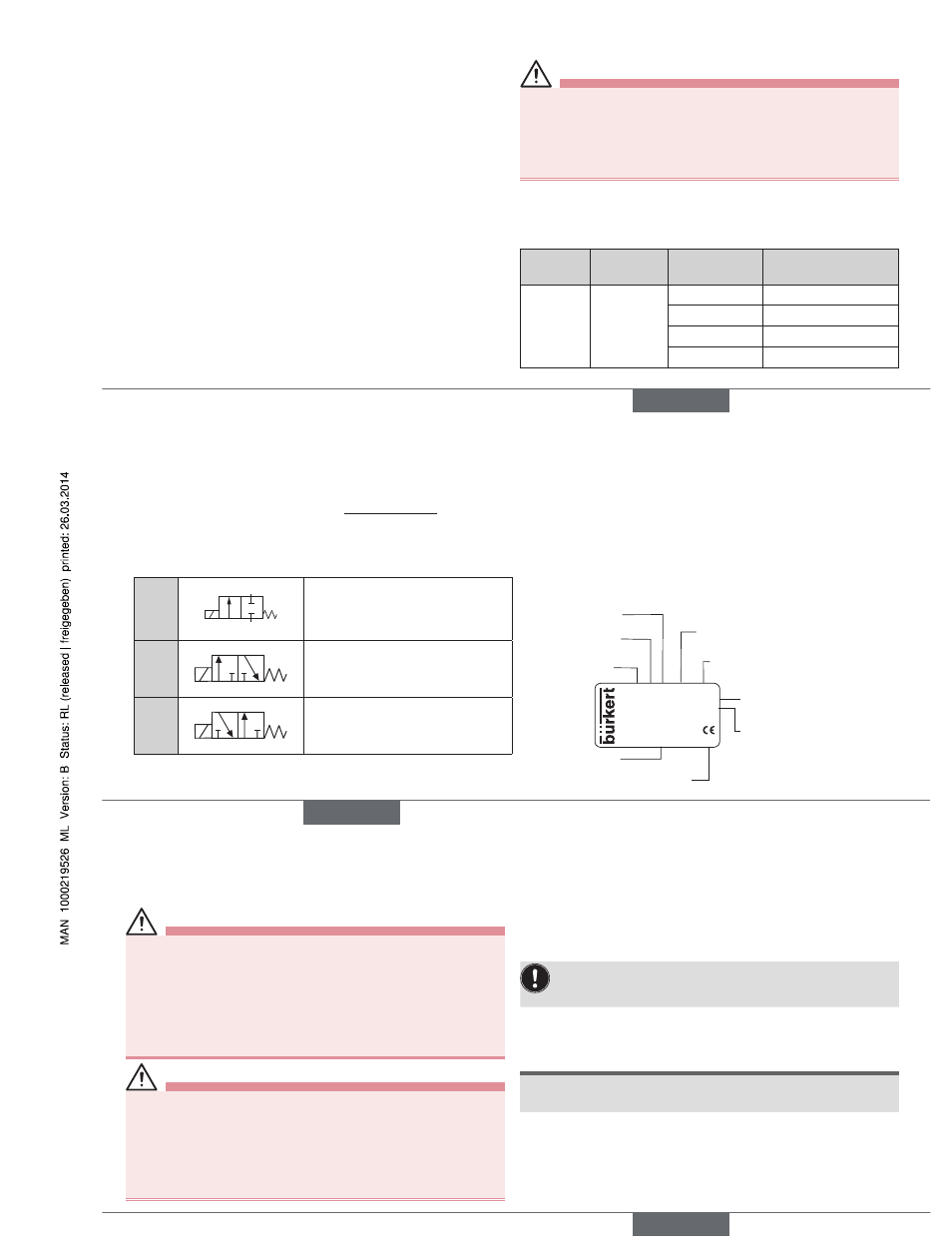

5.4 Fluidic data

Circuit function

A

(NC)

1 (P)

2 (A)

2/2-way valve, normally closed

C

(NC)

2(A)

1(P) 3(R)

3/2-way valve, direct-acting,

output A normally unloaded

D

(NO)

2(B)

1(P) 3(R)

3/2-way valve, direct-acting,

output B normally pressurized

Pressure range

see type label

Line connectors

G 1/8, G 1/4, NPT 1/8, NPT 1/4, Flange

5.5 Electrical data

Connections

Terminal box, permanently installed cable

Operating voltage

see type label

Voltage tolerance

± 10 %

Protection class

IP65 in accordance with DIN EN 60529 /

IEC 60529

Viscosity

21 mm

2

/s

5.6 Type label

Type

Circuit function

Orifice

Sealing material

Body material

Id. Number

Manufacturer code

Voltage, Frequency,

Power consumption

Connection thread, Operating

pressure

0641 A 3,0 FKM MS

Made in Germany

00050443

W12MN

24V AC/DC 7 W

G 1/4 P

N 0

- 4 bar

english

9

6

INSTALLATION

6.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

▶ Before loosening the pipes and valves, turn off the pressure and vent

the lines.

Risk of injury due to electrical shock!

▶ Before reaching into the device or the equipment, switch off the power

supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for

electrical equipment.

WARNING!

Risk of injury from improper installation!

▶ Installation may be carried out by authorized technicians only and with

the appropriate tools.

Risk of injury from unintentional activation of the system and an

uncontrolled restart!

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

6.2 Fluid installation

Installation position: any, actuator preferably upwards.

Procedure:

→

Clean any possible dirt off the pipelines and flange connections.

→

Install a dirt trap to prevent malfunctions (0,2 ... 0,4 mm).

Observe direction of flow:

from 1(P) → 2(A) (circuit function A) / (circuit function C), or

1(P) → 2(B) (circuit function D).

Valve with threaded connection:

→

Use a suitable sealing material.

NOTE!

Caution risk of breakage!

• Do not use the coil as a lever arm.

→

Hold the valve with the appropriate tool on the body and screw into

the pipeline.

english

Type 0641