Burkert Type 0407 User Manual

Page 3

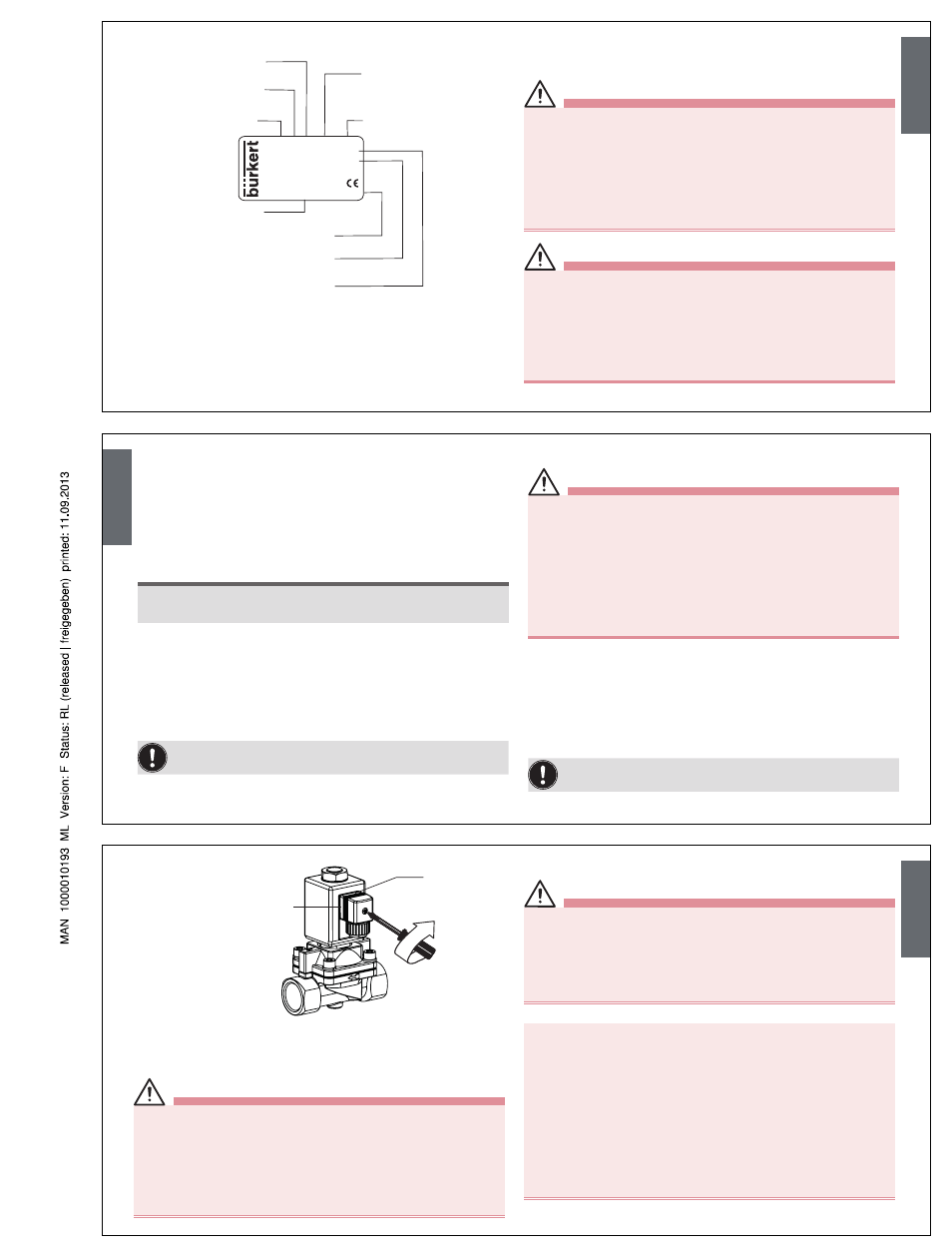

5.5. type label

Type

Operating

principle

Orifice

Seal material

Body material

Id.-Number

Manufacture-Code

Voltage, Frequency, Power

consumption

Connection thread, Nominal

pressure

0406 A 13,0 EG MS

Made in Germany

00042005

W17MG

24 V DC 8 W

G1/2 P

N 1

-

4 bar

6.

installatiOn

6.1. safety instructions

DAnGer!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

WArnInG!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians only and

with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

english

6.2. before installation

Installation position: any, actuator preferably upwards.

Procedure:

→

Check pipelines for dirt and clean.

→

Install a dirt filter before the valve inlet (≤ 500 µm).

6.3. installation

note!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

→

Hold the device with a open-end wrench on the body and screw

into the pipeline.

→

Use PTFE tape as sealing material.

→

Observe direction of flow:

The arrow on the body indicates the direction of flow.

→

Align pipelines.

Valve body must not be installed under tension.

6.4. electrical connection of the cable plug

WArnInG!

Risk of injury due to electrical shock!

• Before reaching into the system, switch off the power supply and

secure to prevent reactivation!

• Observe applicable accident prevention and safety regulations for

electrical equipment!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Always connect protective conductor.

• Check electrical continuity between coil and body.

Procedure:

→

Tighten cable plug (for permitted types see data sheet), observing

max. torque 1 Nm.

→

Check that seal is fitted correctly.

→

Connect protective conductor and check electrical continuity

between coil and body.

Note the voltage and current type as specified on the type

label.

english

Authorized cable plug e.g.

Type 2508 or other suitable

cable plug in accordance with

DIN EN 175301-803 Form A

Seal

max. 1 Nm

7.

maintenance, trOubleshOOting

7.1. safety instructions

WArnInG!

Risk of injury from improper maintenance!

• Maintenance may be carried out by authorized technicians only

and with the appropriate tools!

Risk of injury from unintentional activation of the system and

an uncontrolled restart!

• Secure system from unintentional activation.

• Following maintenance, ensure a controlled restart.

7.2. installation of the coil

WArnInG!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and vent

the lines.

If the protective conductor contact between the coil and body

is missing, there is danger of electrical shock!!

• Check protective conductor contact after installing the coil.

Escaping medium!

When a sticking nut is loosened, medium may escape.

• Do not tighten sticking nut any further.

Electric shock!

If the protective conductor contact between the coil and body is

missing, there is danger of electrical shock!

• Check protective conductor contact after installing the coil.

Danger due to electrical shock if coil incorrectly installed!

• During installation ensure that the coil is situated firmly on the body

cover so that the protective conductor connection of the coil is con-

nected to the valve body.

english