Dsc4, Instruction manual model – EBARA DSC4 User Manual

Page 9

24

INSTRUCTION MANUAL

Model

DSC4

(4) Rotor

(a) After checking the oil, put your hand through the pump discharge and turn the impeller.

If it turns smoothly, the rotating components should be in satisfactory condition.

(b) If the impeller resists or feels locked, the pump requires overhaul.

6.3.3 Reinstallation

After the pump has been thoroughly inspected, reinstall it by reversing the lifting procedure.

If dirt is caught in the elbow, lift the pump back a little and operate pump for 2 or 3 seconds to

blow off the dirt.

6.4 Overhaul

Whenever the pump requires overhaul due to operational problems, poor insulation or as a

result of inspection, returns it to us for the job.

Pumps should be overhauled for general inspection every second year to prevent major troubles

even if there are no apparent problems.

(1) Cable disposition

When the pump is lifted for overhaul, it is necessary to disconnect all cables from the

control panel terminal board. At this time, if the cables are pulled out from the fl oor-level

elbow, reinstallation becomes diffi cult.

To prevent this, pull the cables with their ends tied with string. When the cables are put

back into their original position after overhaul, tie the cables ends again with the same

string and pull from the opposite side.

(2) Details of overhaul

Overhaul consists of the following work (to be done at our shop) :

(a) Complete disassembly, inspection and cleaning of pump.

(b) Inspection of starter coil and insulation test.

(c) Replacement of worn and damage parts.

(d) Functional tests.

(e) Performance tests. (If required)

6.5 Disassembly and Reassembly

WARNING: WHEN DISASSEMBLING THE PUMP, WARNING SIGNS MUST BE POSTED

NEARBY TO PREVENT MISOPERATION BY THIRD PARTIES. FAILURE TO OBSERVE THIS

PRECAUTION CAN RESULT IN DAMAGE OR SERIOUS ACCIDENTS.

WARNING: DURING PUMP DISASSEMBLY AND REASSEMBLY, ENSURE THAT THE

CABLES ARE DISCONNECTED AND ISOLATED FROM THE POWER SUPPLY.

09

INSTRUCTION MANUAL

Model

DSC4

Use one of the following

oils or equivalent.

Shell : Turbo oil T32

Mobil : Mobil DTE oil light

Esso : Esso Tresso 32

Exxon : Teresstic 32

Gulf

: Harmony 32, Crest 32

Caltex : Rega Oil R&O 32

Table 1

PUMP

MODEL

MODEL

CODE

APPROX.

OIL CAPACITY

(LITER)

PUMP

MODEL

MODEL

CODE

APPROX.

OIL CAPACITY

(LITER)

150DSC4

AO-46075

2.4

300DSC4

FO-66060

FC-66060

2.4

150DSC4

AO-46060

AC-46060

300DSC4

FO-66050

FC-66050

150DSC4

AO-46050

AC-46050

300DSC4

GO-66075

GC-66075

2.3

150DSC4

BC-46120

2.4

150DSC4

HO-46075

HC-46075

3.2

150DSC4

BC-46100

3.1

150DSC4

HO-46060

HC-46060

150DSC4

CC-46145

3.2

150DSC4

HO-46050

HC-46050

250DSC4

EO-66145

EC-66145

3.9

250DSC4

EO-66125

EC-66125

250DSC4

EO-66100

EC-66100

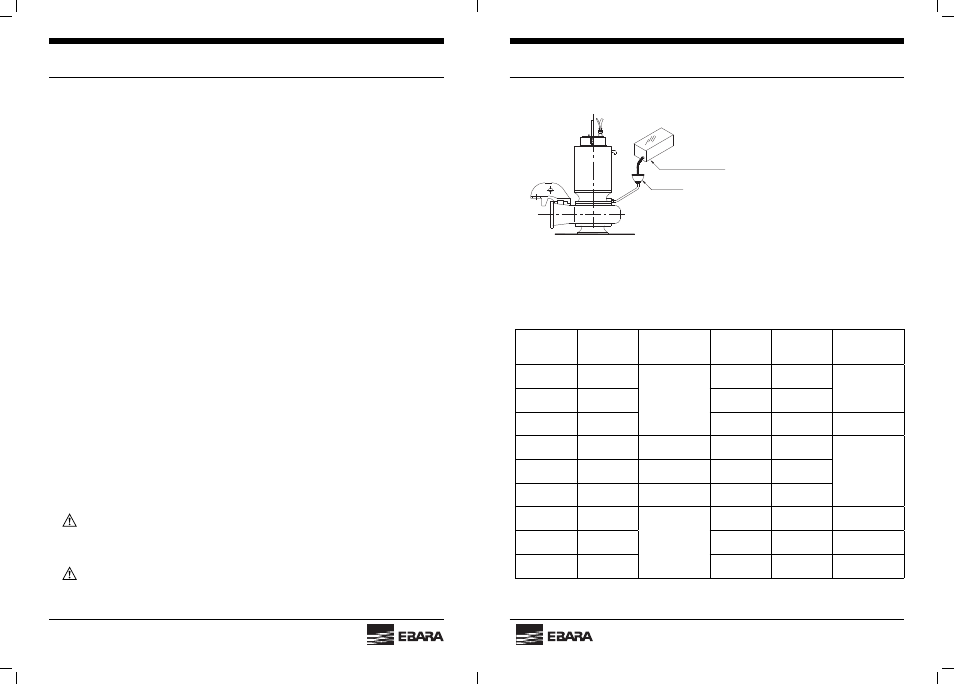

Floor surface

Oil funnel

Turbine Oil ISOVG32

Fig. 9