Dsc4, Instruction manual model – EBARA DSC4 User Manual

Page 4

04

INSTRUCTION MANUAL

Model

DSC4

1. Preface

Design of this EBARA pump is based on superior engineering and long experience. To prevent

trouble and provide satisfactory operation and long life, it is important to understand the EBARA

pump thoroughly by careful study of this manual. If any questions arise regarding this manual,

please direct them to EBARA. Your questions will be promptly answered and your suggestion

may be considered for incorporation into our future products.

CAUTION: THIS INSTRUCTION MANUAL INCLUDES NECESSARY ITEMS FOR

INSTALLATION, OPERATION AND MAINTENANCE. READ THIS MANUAL CAREFULLY TO

ENSURE CORRECT INSTALLATION, OPERATION AND MAINTENANCE.

BE SURE TO KEEP THIS INSTRUCTION MANUAL ON HAND FOR FUTURE REFERENCE.

Safety Labels

Four different types of safety labels are used in this manual. Please study the labels carefully so

that the meaning of any safety warning you encounter is immediately clear.

DANGER: indicates a potentially hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury

CAUTION: indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury or possible damage to the

equipment or machine.

Note: is used to call attention or to emphasize essential information.

2. Acceptance Inspection

Upon arrival of the pump –

(1) Check the nameplate information for agreement with specifi cations in respect to model

identifi cation, head, pumping capacity, speed, output, voltage and frequency.

(2) Check the pump has not been damaged during shipment and all plugs and fastening bolts

properly tightened.

(3) Check accessories and spare parts against the packing list.

If any problem is found, contact your dealer.

29

INSTRUCTION MANUAL

Model

DSC4

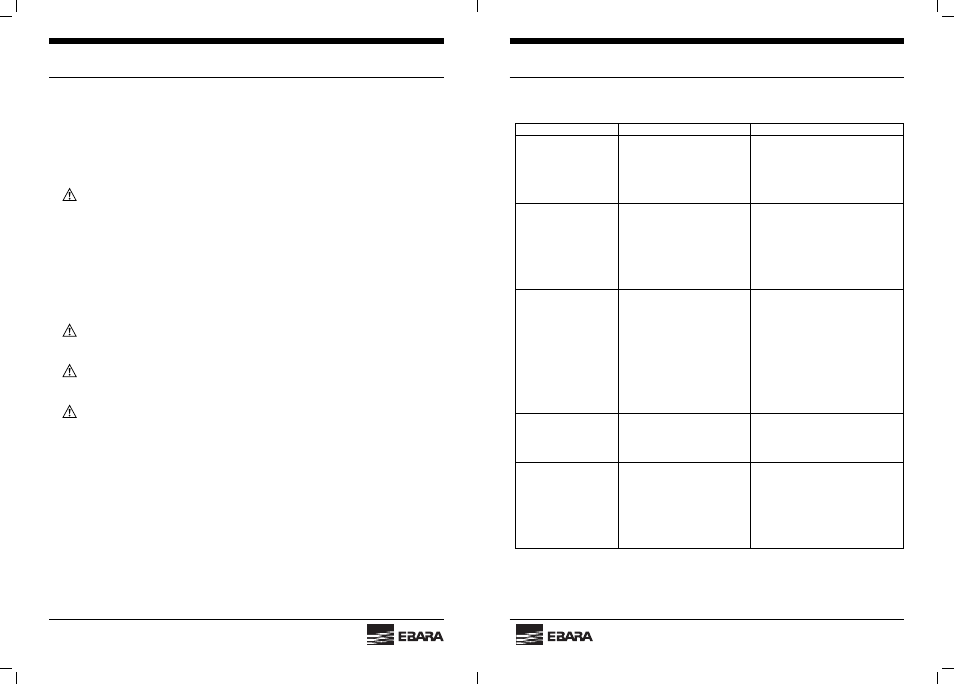

7. Troubleshooting

Symptoms

Probable Causes

Remedies

Pump fails to start

• Defective cable or motor.

• Malfunction inside control panel.

• Power source trouble.

• Pump is mechanically locked.

• Defective protector.

• Lifts pump and replace cable or motor.

• Inspection made by competent

electrician.

• Inspection made by competent

electrician.

• Lift pump, inspect and/or overhaul.

• Replace protector.

Pump fails to function

despite motor operation

• System head too high.

• Clogged discharge pipe (Pressure

too high).

• Clogged pump or strainer

(Pressure too low).

• Wrong direction rotation.

• Internal pump wear.

• Valve is closed.

• Recheck requirements.

• Clean discharge pipe.

• Clean strainer or impeller and casing.

• Check and change rotation. Transpose

two of three phase leads at panel.

• Repair and/or replace.

• Check valve operation.

Insuffi cient capacity

• Air suction.

• System head too high.

• Clogged discharge pipe.

(Pressure too high)

• Clogged pump or strainer.

(Pressure too low)

• Air accumulation in pipe.

• Internal pump wear.

• Wrong direction rotation.

• Liquid viscosity different from

design value.

• Damaged impeller.

• Raise water level in pump pit.

• Recheck requirements.

• Clean discharge pipe.

• Clean strainer, impeller and bowl.

• Install air vent valve.

• Repair and/or replace.

• Check and change rotation. Transpose

two of the three phase leads at panel.

• Recheck requirements.

• Repair and/or replace

Excessive current

• Gravity of pumped liquid greater

than that specifi ed.

• Sand mixed with water.

• Refer to “Pump fails to start”

• Change pump unit.

• Lift the pump and overhaul. Remove

sand in tank.

Vibration and/or noise

• Internal pump wear.

• Clogged pump.

• Cavitation or vortex.

• Resonance in pipe line or

foundation.

• Rotating component in contact

with fi xed component.

• Damaged impeller.

• Repair and/or replace.

• Clean pump.

• Raise suction water level. Operate at

proper fl ow rate.

• Repair to change characteristic

vibration.

• Internal pump check.

Repair and/or replace.

• Repair and/or replace.