Dsc4, Instruction manual model – EBARA DSC4 User Manual

Page 8

08

INSTRUCTION MANUAL

Model

DSC4

3.6 Check the Followings Points (1) through (6) Prior to Pump Installation

(1) Ensure that the mechanical seal chamber is fi lled with specifi ed amount of oil.

(2) All plugs and fastening bolts are properly tightened.

(3) The sealing chamber is not leaking.

(4) The pump is not damage and the cable glands and cables are in satisfactory

condition.

(5) Insulation resistance values are within limits. (See 3.6.2)

(6) Other points that require particular attention. (See 3.6.3)

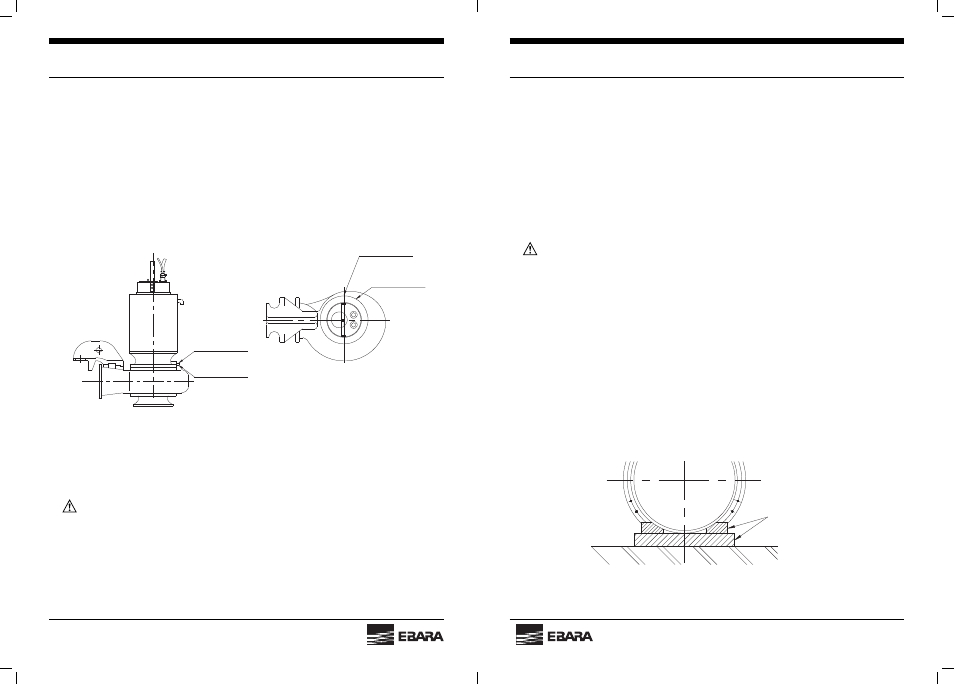

3.6.1 Oil Supply (Fig. 7, 8 and 9)

The motor shaft is sealed with a tandem mechanical seal. The seal chamber provide between the

two sealing stages can be fi lled with turbine oil by standing the pump vertically and unplugging

“oil port” and “air vent”.

CAUTION: THE SEAL CHAMBER MAY BE UNDER PRESSURE. HOLD A RAG OVER THE

OIL PLUG TO PREVENT SPPLATTER.

Pour the specifi ed oil into the sealing chamber through the “oil port” until the oil fl ows out of the

“air vent”. (See Table 1)

After the sealing chamber is fi lled to the specifi ed level, put a sheet gasket between the plug

and the boss, and tighten the plug.

Mech. Air vent.

Mech. Oil port

Mech. Air vent.

Mech. Oil port

Fig. 7 Fig. 8

25

INSTRUCTION MANUAL

Model

DSC4

6.5.1 Preparation for Disassembly and Reassembly

An adequate workspace should be found which is as wide as possible, and has a rigid fl oor.

The area should be safe from hazards. The following should be prepared before disassembly

and reassembly.

• Lifting devices.

• Wooden supports and pads.

• Standard tools.

• Special tools.

• Tefl on tape or liquid packing.

• Rags.

WARNING: DURING DISASSEMBLY AND REASSENBLY, BE SURE TO USE APPROPRIATE

CRANE (OR HOST) AND WIRE ROPES. USE OF IMPROPER CRANE AND WIRE ROPES CAN

RESULT IN SERIOUS ACCIDENTS.

FAILURE TO OBSERVE THIS PRECAUTION CAN RESULT IN SERIOUS ACCIDENTS.

6.5.2 Cautions for Disassembly

(1) Cautions for unloading products

(a) When hoisting heavy loads such as the pump proper, pay careful attention to attaching

the sling so that the load will be centered and the sling does not slip.

(b) When lifting heavy parts, use soft padding under the wire to protect the coated and

machined surfaces. Do not raise or lower the parts too rapidly with the crane.

(c) When assembling components on the fl oor, use protective blocks under the

components to protect the coated surfaces and prevent rolling.

Fig. 21

Protective blocks