Dsc4, Instruction manual model – EBARA DSC4 User Manual

Page 5

28

INSTRUCTION MANUAL

Model

DSC4

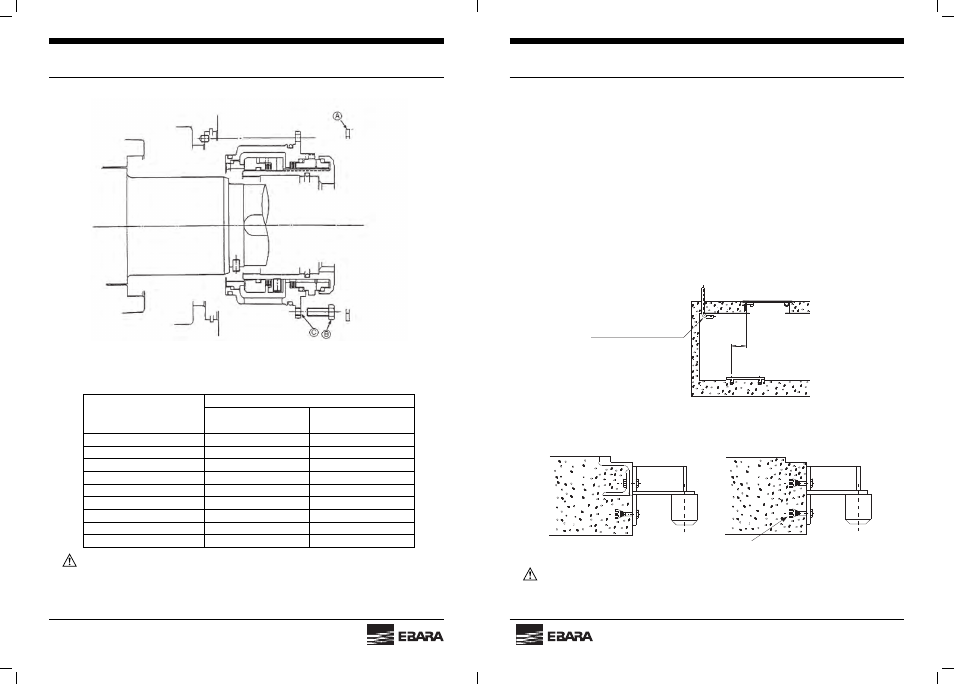

Fig. 24

(4) Torque table

Table 4

WARNING: WHEN MACHINES SURFACES ARE DAMAGED AND MUST BE REPAIRED, USE

AN APPROPRIATE GRINDER. DURING GRINDING WORK, APPROVED PROTECTIVE GOOGLES

MUST ALSO BE WORN.

Motor side

Impeller side

Bolt Size

Torque kg.m (Ft.lbs.)

Without anti seized

compound

With anti seized

compound

M8

1.1 (8)

0.8 (6)

M10

2.2 (16)

1.5 (11)

M12

3.8 (28)

2.6 (18)

M16

9.1 (66)

6.2 (45)

M20

17.8 (129)

12.1 (88)

M22

24.0 (174)

16.2 (117)

M24

30.8 (223)

20.9 (151)

M30

61.4 (444)

41.6 (301)

M36

107.0 (774)

72.4 (524)

05

INSTRUCTION MANUAL

Model

DSC4

3. Installation

3.1 Foundation

Place concrete to build up the fl oor and discharge elbow foundations to the values shown in

installation drawing. The discharge elbow foundation must have suffi cient size and strength to

support the weight of the pump body, submersible motor and accessories plugs the weights of

the discharge pipe, and to absorb vibrations and impacts resulting from operation. Usually, it

should weigh more than seven times the pump weight.

3.2 Floor Frame (Fig. 1, 2 and 3)

Install a cable lead-out elbow and a fl oor frame on the fl oor over the pump pit. Attach a guide

pipe holder securely to the fl oor frame with bolts. As the guide pipe must be installed vertically

(with a tolerance of 1mm or less per 1m), carefully check the positional relationship between

the fl oor frame location and the discharge elbow foundation. (See Fig. 1 * )

If the guide pipe holder is attached directly to the concrete, use hole-in anchor bolt as shown

in Fig. 3.

CAUTION: IF THE CABLE LEAD-OUT ELBOW IS TOO SMALL IN DIAMETER, THE CABLE

MAY BE HEATED WHERE IT RUNS THROUGH THE ELBOW.

*

Cable lead-out elbow

Fig. 1

Fig. 2 Fig. 3

Hole-in anchor bolt