Mhm5 – BEI Sensors MHM5 Absolute Hollow Shaft Encoder User Manual

Page 2

MHM5

CANOPEN ABSOLUTE MULTI-TURN ENCODER, MHM510-CANO

RANGE

ELECTRICAL DATA

Interface

ISO 11898

Power consumption

max 2,5W

Transmission rate

Max 1 MBauds

Step Frequency LSB

800 kHz

Device addressing

by rotary switches

Accuracy

+ ½ LSB

Power supply

10 – 30Vdc

EMC

EN 61000-6-4 EN 61000-6-2

Current consumption

max 100mA (24Vdc)

Electrical lifetime

> 10

5

h

TRANSMISSION MODES

POLLED Mode

By a remote-transmission-request telegram the connected host calls for the current process value. The

absolute rotary encoder reads the current position value, calculates eventually set-parameters and sends

back the obtained process value by the same identifier

CYCLIC Mode

The absolute rotary encoder transmits cyclically - without being called by the host - the current process

value. The cycle time can be programmed in milliseconds for values between 1 ms and 65536 ms

SYNC Mode

After receiving a sync telegram by the host, the absolute rotary encoder answers with the current process

value. If more than one node number (encoder) shall answer after receiving a sync telegram, the answer

telegrams of the nodes will be received by the host in order of their node numbers. The programming of an

offset-time is not necessary. If a node should not answer after each sync telegram on the CAN network, the

parameter sync counter can be programmed to skip a certain number of sync telegrams before answering

again

PROGRAMMABLE PARAMETERS

Operating

Parameters

This parameter determines the counting direction, in which the output code increases or decreases. As an

important operating parameter the code sequence (complement) can be programmed

Resolution per turn

Value between 1 and 8192 can be programmed

Total resolution

‘’Max range’’

This parameter is used to program the desired number of measuring units over the total measuring range.

This value may not exceed the total resolution of the absolute rotary encoder.

Preset Value

The preset value is the desired position value, which should be reached at a certain physical position of the

axis

Limit Switch,

Min. and Max

Two position values can be programmed as limit switches. By reaching these values one bit of the 32 bit

process value is set to high level

Cam

One free programmable cam can be set in the total measuring range

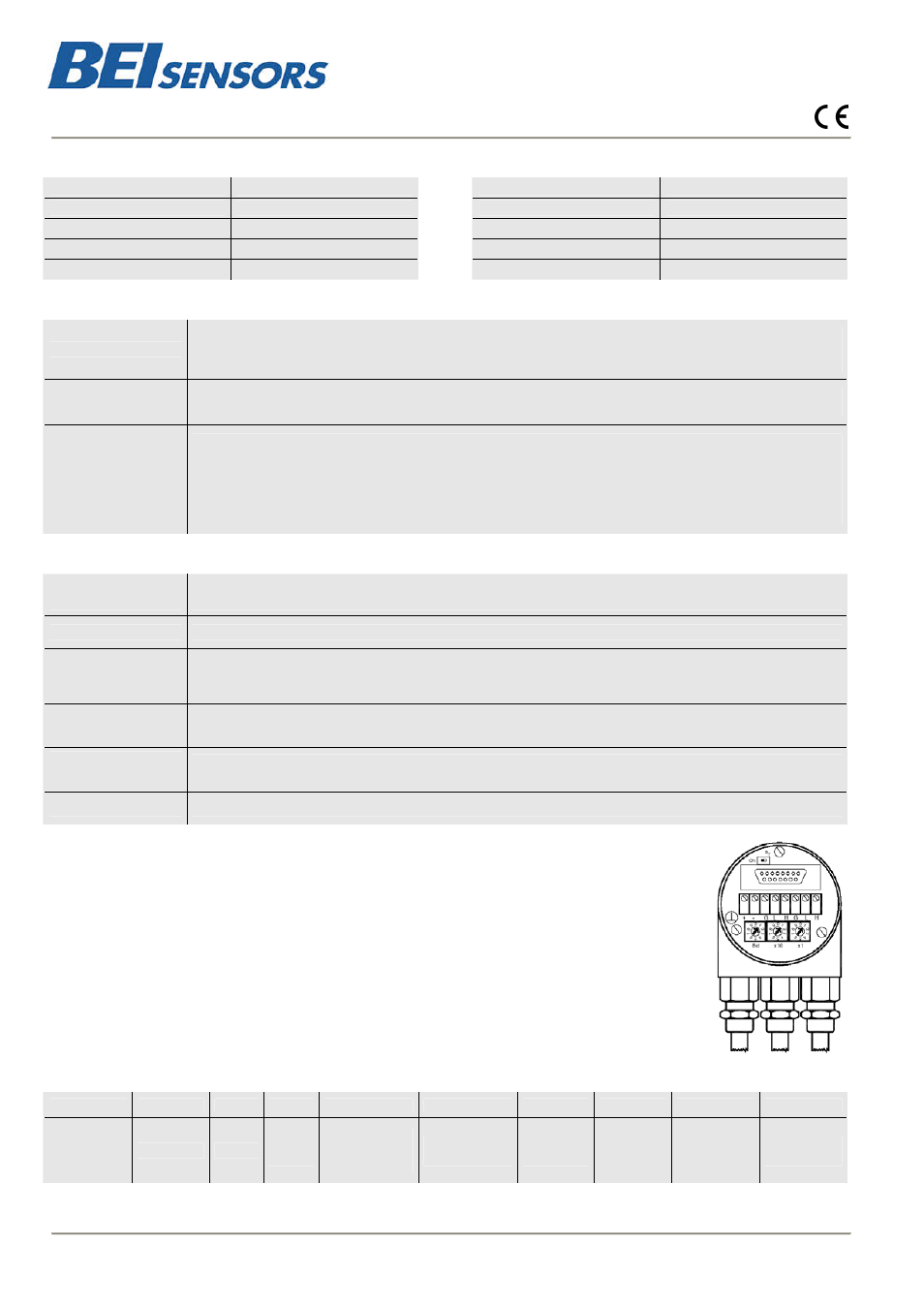

INSTALLATION

The rotary encoder is connected by two or three cables depending on whether the power supply is

integrated into the bus cable or connected separately. If the power supply is integrated into the bus

cable, one of the cable glands can be fitted

with a plug. The cable glands are suitable for cable diameters from 5.5 up to 9 mm

CONFIGURATION

The setting of the node number is achieved by 2 turn-switches in the connection cap. Possible

addresses lie between 0 and 89 whereby every address can only be used once. Inside the encoder

the defined address is increased by one. The connection cap can easily be opened for installation

by removing the two cap screws

A termination resistor is integrated in the connection cap. The resistor must be switched on if the

encoder is connected at the end or at the beginning of the bus

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél

: +33 (0)3 88 20 80 80

Fax

: +33 (0)3 88 20 87 87

Web :

www.beisensors.com

ORDERING REFERENCE

(Contact the factory for special versions ex:electronics, special flanges, connections…)

MHM5

CA

A1

B

12

13

C

10

0

H3P

Absolute

multi turn

encoder

CANopen Version

Code :

Binary

Number of

turns

2

12

(4 096)

Resolution :

2

13

(8 192)

Clamp

flange

Shaft

diameter :

10mm

Without

mechanical

option

Connection

Cap

Note:

The ‘’H3P’’ terminal box version is shorter than the ‘’0CC’’ one.

Changes possible without further notice - Version 100629