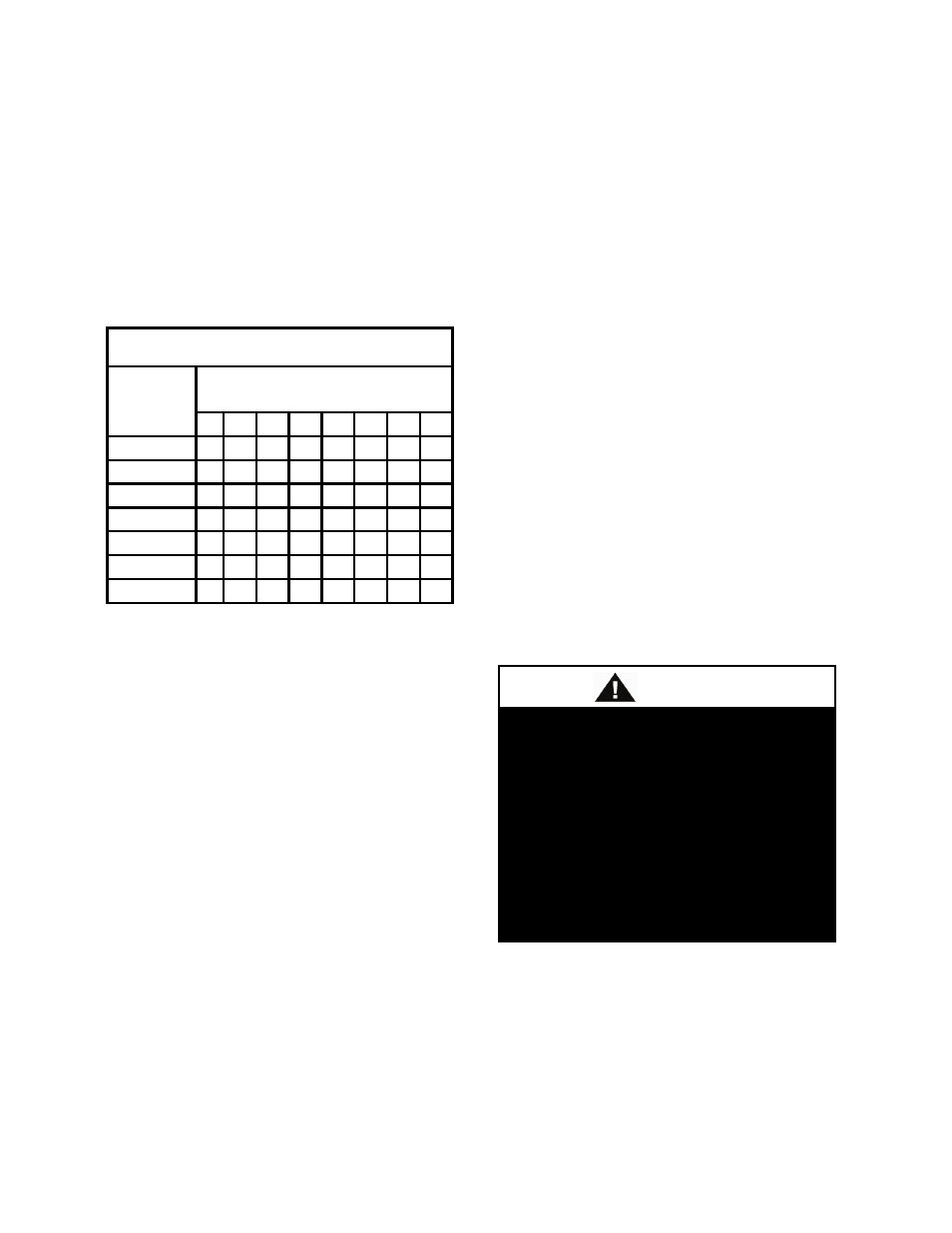

Condenser flooding, Electrical, Table 1 - condenser flooding – AAON LC-054 User Manual

Page 18: Warning

18

Condenser Flooding

In order to maintain head pressure in the

refrigeration system, liquid refrigerant is

kept in the condenser to reduce condenser

surface. The following chart shows the

percentage that a condenser must be flooded

in order to function properly at the given

ambient temperature.

Table 1 - Condenser Flooding

PERCENTAGE OF CONDENSER TO BE

FLOODED

Ambient

Temperature

(

°

F)

Evaporating Temperature (

°

F)

0

°

10

°

20

°

30

°

35

°

40

°

45

°

50

°

70

°

40 24 0

0

0

0

0

0

60

°

60 47 33 17 26 20 10 4

50

°

70 60 50 38 45 40 33 28

40

°

76 68 60 50 56 52 46 42

30

°

80 73 66 59 64 60 55 51

20

°

86 77 72 65 69 66 62 59

0

°

87 83 78 73 76 73 70 68

During higher ambient temperatures the

entire condenser is required to condense

refrigerant. During these higher ambient

temperatures, a receiver tank is used to

contain the refrigerant that was required to

flood the condenser during low ambient

operation. The receiver must be sized to

contain all of the flooded volume otherwise

there will be high head pressures during

higher ambient conditions.

Electrical

The single point electrical power

connections are made in the electrical

control compartment. The microprocessor

control furnished with the unit is supplied

with its own power supply factory wired to

the main power of the chiller.

Check the unit nameplate voltage to make

sure it agrees with the power supply.

Connect power to the unit according to the

wiring diagram provided with the unit.

Note: Units are factory wired for 208V,

230V, 460V, or 575V. In some units, the

208V and 230V options may also be

provided in single or three phase

configurations.

The transformer

configuration must be checked by a

qualified technician prior to startup.

The power and control wiring may be

brought up through the utility entry. Protect

the branch circuit in accordance with code

requirements. Control wires and power

should not be run inside the same conduit.

The unit must be electrically grounded in

accordance with the current National

Electric Code.

Power wiring is to the unit terminal block or

main disconnect. All wiring beyond this

point has been done by the manufacturer and

cannot be modified without effecting the

unit’s agency/safety certification.

Note: Startup technician must check motor

amperage to ensure that the amperage listed

on the motor nameplate is not exceeded.

Electric shock hazard. Before

attempting to perform any installation,

service, or maintenance, shut off all

electrical power to the unit at the

disconnect switches. Unit may have

multiple power supplies. Failure to

disconnect power could result in

dangerous operation, serious injury,

death or property damage.

WARNING