Primary pumping package, Glycol, Compression/expansion tank – AAON LC-054 User Manual

Page 14: Pressure relief valve, Manual and automatic air vent

14

Primary Pumping Package

Primary pumping uses a single pump to

move water (or glycol) through the

evaporator and back to the building. This

pumping package provides the necessary

flow of water to the system. The pump is

activated whenever the chiller is given a run

signal.

Water enters the unit through the return

water piping, and then travels through an air

scoop to remove any air that is entrapped in

the water. Following this, the water flows

through a suction guide with strainer. The

end of the suction guide is removable for

strainer access. The strainer assembly is

composed of two parts, the operational

strainer, and the startup strainer, (located

inside the operational strainer) which is to

be removed 24 hours after startup.

The pump is installed after the suction

guide, and before a combination valve (Flo-

Trex). This combination valve acts as

isolation valve, check valve, and flow

balancing valve. The shell and tube or

brazed plate evaporator, is placed after the

combination valve in the water circuit, with

a differential pressure switch installed across

its inlet and outlet. This pressure switch

closes when the differential pressure

increases above the set-point, which should

be set 1-2 psig below the pressure drop

across the heat exchanger at design flow

rate. The closing differential pressure switch

signals the control system to indicate flow

through the heat exchanger and allow

cooling to activate as required to maintain

the setpoint. The water exiting the shell and

tube or brazed plate evaporator, leaves the

unit through the water out connection.

Glycol

Glycol units require a glycol feeder field

installed to replace fluid that is lost in the

system. Water should not be directly added

to glycol applications as this would dilute

the glycol concentration and thereby

increase the freezing temperature of the

fluid.

Compression/Expansion Tank

As the water temperature in the system

increases, the volume that water displaces

increases. In order to compensate for these

forces, AAON recommends a pre-

pressurized diaphragm compression tank

that is preset for 12 psig.

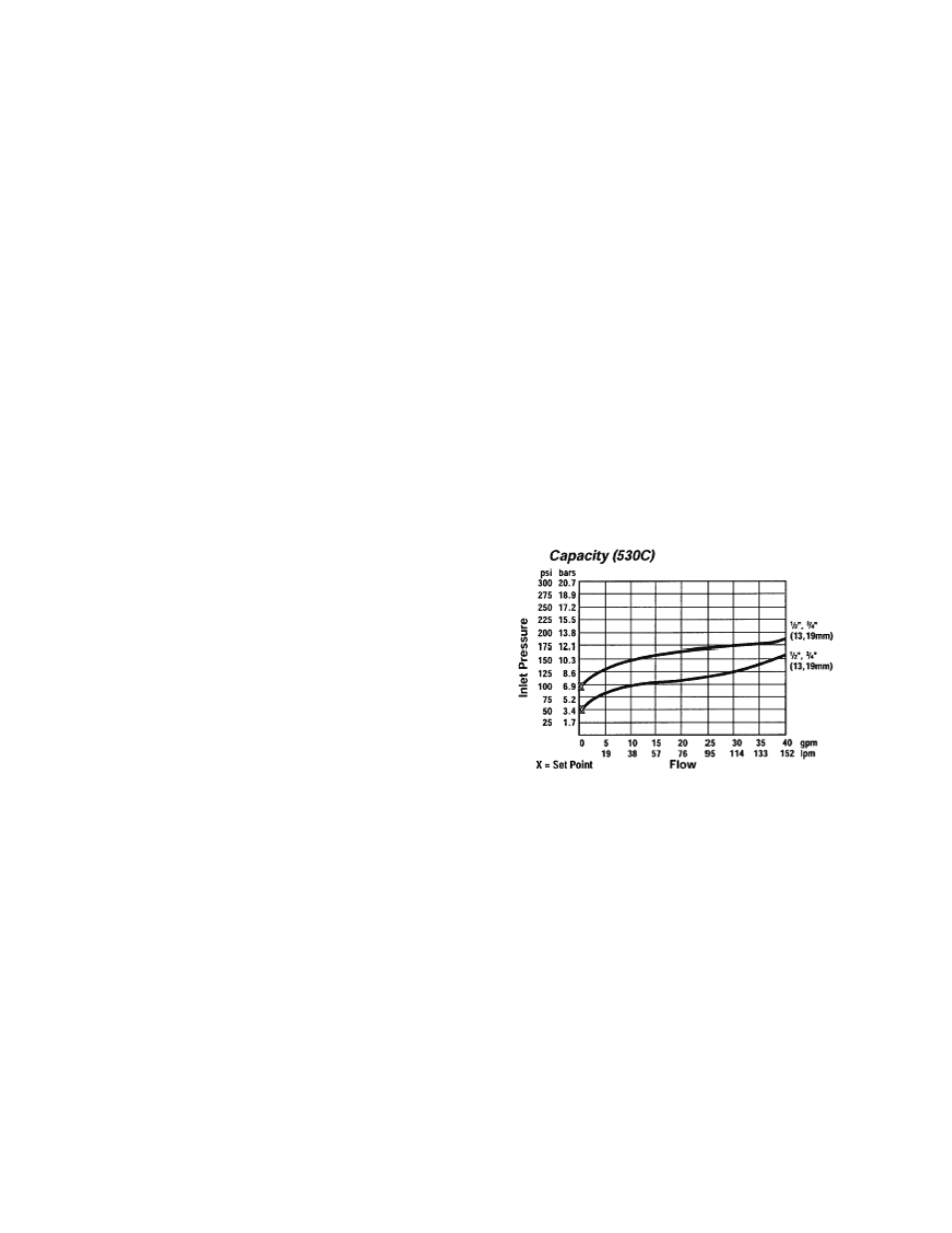

Pressure Relief Valve

Required pressure relief valve is installed in

the unit. This valve is set at 125 psig. Figure

1 shows inlet pressure versus capacity for

this pressure relief valve. See appendix for

additional information.

Figure 1 - Pressure Relief Valve

Manual and Automatic Air Vent

A manual air vent is supplied in chillers

without pumping packages. With a pumping

package option, there is an air scoop

installed at the high point of the system.

The air vent valve must be in the proper

position for operation. Ensure that the small

vent cap on the automatic air vent is

loosened one to two turns from the closed

position, allowing air to be vented from the

system. It is advisable to leave the cap on to

prevent impurities from entering the valve.

See appendix for additional information.