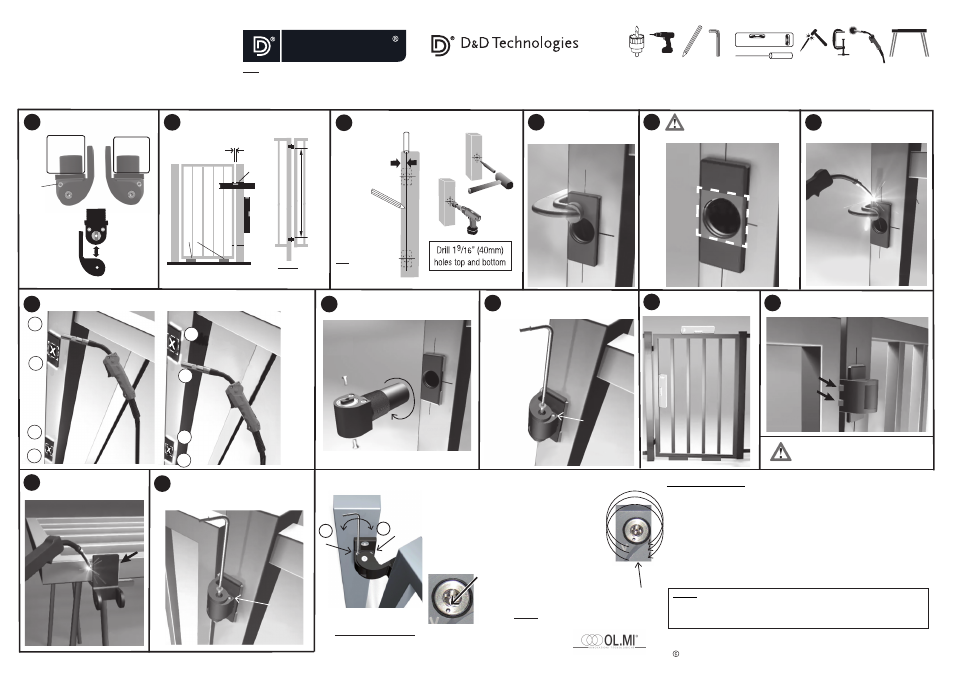

D&D Technologies SureClose Flush Mount Weld-On User Manual

Close, Sure, Flush mount weld-on

GAP:

5

/

16

”-

1

/

2

”

(8-13mm)

1

Hi-Performance Hardware

Installation Instructions

4

DO NOT WELD RESTRICTED AREA

SURE

Close

NOTE: If using SM hinge, always install at bottom of gate.

57 and 108 models should be installed on top.

3, 4, 5mm

1

9

/

16

”

(40mm)

18V

Laser level

Pencil

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

DETERMINE THE HANDING

Adjustment

Nozzles

must be

on top

Remove

Gate Bracket

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

Mark hinge center lines

MARKING HEIGHTS

Support Blocks

Ensure post is vertical in the

front and side elevations

2

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

MARK TOP AND BOTTOM BRACKETS ON POST

Ensure drill hole will

clear the post wall

thickness.

7

/

8

”-1

1

/

16

”

(22-27mm)

Laser Level

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

NOTE: Apply corrosion

protection to exposed

metal surfaces.

3

6

8

1

2

3

4

5

9

12

13

CORRECT WELDING SEQUENCE TO PREVENT BRACKET OVERHEATING AND THREAD WARPING

ENSURE BRACKET IS COOL BEFORE

INSERTING HINGE

REPLACE HINGE BRACKET

REMOVE GATE AND COMPLETE

WELDING - ALLOW COOLING

Welder

2 x Clamps

2 x Horses

CLAMP POST BRACKET

INTO PLACE

REPLACE GATE AND FASTEN THE TWO PINS

6

7

8

X

FLUSH MOUNT WELD-ON

5

WELD ONE SURFACE ONLY

AND MOVE TO BOTTOM HINGE

10

POSITION GATE LEVEL

TACK WELD BRACKET ONTO GATE

11

(V)

+

–

(S)

ADJUSTING THE CLOSING SPEED AND FINAL ‘SNAP’ ACTION (108 ONLY)

CAUTION: Sensitive adjustment, rotate MAX 1/4 turn at a time.

V = Closing Speed S = Final Snap Action

Turn nozzles clockwise to decrease speed & counterclockwise

to increase speed.

IMPORTANT:

Use dimple to determine how far nozzle has turned.

DO NOT

turn adjustment nozzles more than 3 complete rotations.

DO NOT

unscrew nozzle past the surface of the body.

CAUTION: DO NOT

remove adjustment nozzles or disassemble

hinge. Doing so voids warranty.

If using a 57+57 or 108+108 combination, each closer

must have equal closing speed at all times.

MAINTENANCE REQUIREMENTS

• A

Gate stop must be installed when using SF models. Gate must not be allowed to open past 90

˚

.

Doind so voids warranty.

• Never use more than two (2) SureClose hinge/closers on any one gate.

• Remove all other types of hinges and self-closing devices.

• Ensure the gate does not swing through the line of the fence. Use a “gate stop” or a latch (with striker)

to prevent this.

• All steel mounting brackets (gate and post) should be painted or powder coated. Spray painting is recommended.

• The anodized aluminum mounting brackets do not need finishing, but they may be painted or powder coated.

• DO NOT powder coat the hinge/closer, but they may be painted.

• DO NOT turn the adjustment nozzles more than two (2) full rotations.

• DO NOT unscrew nozzle past the surface of the body.

• DO NOT remove the adjustment nozzles or disassemble these hinges at any time. Doing so voids warranty.

• Ensure the hinges are kept free of sand, ice and other debris that could impair effective operation.

2 YEAR LIMITED WARRANTY:

For a downloadable Adobe Acrobat (.PDF) version of our 2 YEAR

LIMITED WARRANTY, go to our website at www.ddtechglobal.com

CAUTION: Overheating any SureClose product during welding may cause failure and will void warranty.

To ensure threads on mounting bracket are not deformed, weld one surface at a time and alternate

between top and bottom hinge. Do not weld in restricted area. Finish with appropriate corrosion

protection, avoiding thread contamination.

AUSTRALIA:

Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731

Woodwind Drive, Huntington Beach, CA 92647

www.ddtechglobal.com

Copyright 2012 D&D Group Pty Ltd, Sydney Australia

Neither whole or part of this publication may be

reproduced without prior permission

Patented: CA 2650769; US 7900319; NZ 573211;

AU2010280342, AU2011202070

7

*

CAUTION: When used on

swimming pool gates, always

consult local authorities for

swimming pool Codes.

Distance between hinges 35

1

/

2

” (900mm) minimum

v

Swimming Pool Gates

AU/NZ

Ensure adjustment

nozzles are facing

upwards

Ensure

adjustment

nozzles

are facing

upwards

SCOLM000014P

A 10/2/14

MANUFACTURED BY OL.MI

PRECISION ENGINEERING

A Gate stop must be installed when using SF models.

Gate must not be allowed to open past 90

˚

. Doing so

voids warranty.