D&D Technologies MagnaLatch Top Pull User Manual

Procédure d’installation

For swimming and other child safety gates, most safety standards specify the

following minimum height requirements as being from the bottom of the gate:

1) latch release knob ‘F’ at minimum 54” (1370mm); 2) fence height of between 48” & 72” (1220 &

1830mm). Always confirm these and other requirements with the appropriate pool or safety authorities in your area and install

this latch in accordance with the local fence/barrier codes and regulations. Also, pool gate must open outward, away from the

pool, so this latch must be fitted to the outside of a pool gate. Tools: Electric and cordless drills, drill bits, Phillips No. 2 screwdriver

(hand & powered types). Note: If mounting to steel or vinyl with metal inserts, it is advisable to pre-drill the holes to prevent

screw breakage.

Swimming pool fences, gates and latches cannot substitute for adult supervision. If using this latch on a swimming pool gate, consult all appropriate local

authorities for safety requirements.

The latch will operate properly only if installed and maintained in accordance with these instructions.

MAINTENANCE:

REMOVE KEY FROM LOCK AFTER USE. Do not lubricate the latch with petroleum-based lubricants at any time; use only powdered graphite.

Ensure all screws or bolts are tightened firmly and that the release knob [F] and latching bolt are kept free of sand, ice and other debris which could impair latch

performance. Grind or remove any protruding fasteners after installation.

For a downloadable Adobe Acrobat (.PDF) version of our Limited LIFETIME WARRANTY,

go to our website at www.ddtechglobal.com

INSTALLATION INSTRUCTIONS

For swimming and other child safety gates, most safety standards specify the

following minimum height requirements above the finished ground/fixing surface:

1) latch release knob ‘F’ at minimum 1500mm (59”); 2) fence height of between 1220mm & 1520mm (48” & 60”)

Always confirm these and other requirements with the appropriate pool or safety authorities in your area and install this latch

in accordance with the local fence/barrier codes and regulations. Also, pool gate must open outward, away from the pool, so

this latch must be fitted to the outside of a pool gate. Tools: Electric or cordless drill, drill bits, Phillips No. 2 screwdriver (hand &

powered types). Note: For heavy gauge steel sections it is advisable to pre-drill the holes to prevent screw breakage.

Swimming pool fences, gates and latches cannot substitute for adult supervision. If using this latch on a swimming pool gate, consult all appropriate local authorities

for safety requirements.

The latch will operate properly only if installed and maintained in accordance with these instructions.

MAINTENANCE: REMOVE KEY FROM LOCK AFTER USE. Do not lubricate the latch with petroleum-based lubricants at any time; use only powdered graphite.

Ensure all screws or bolts are tightened firmly and that the release knob [F] and latching bolt are kept free of sand, ice and other debris which could impair latch

performance. Grind or remove any protruding fasteners after installation.

For a downloadable Adobe Acrobat (.PDF) version of our Limited LIFETIME WARRANTY,

go to our website at www.ddtechglobal.com

INSTALLATION INSTRUCTIONS

Installation Procedure

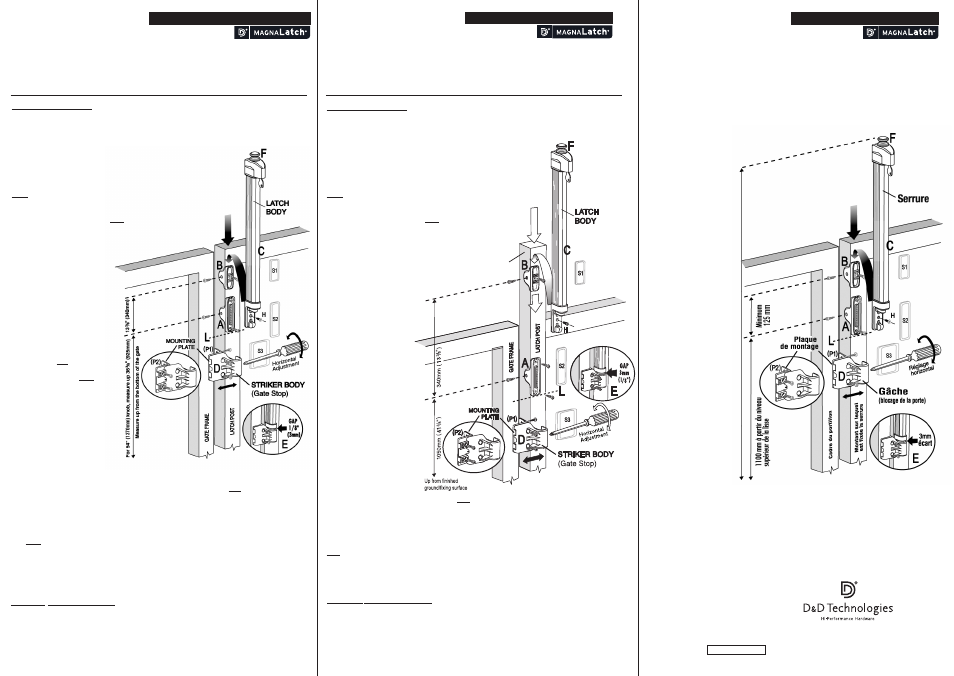

1.

The gap between gate frame and latch post must be between

3

/

8

” (10mm) and 1

7

/

16

” (37mm);

3

/

4

” (19mm) is ideal.

2.

Determine the location of the hole for Mounting Bracket ‘A’ by measuring up from the bottom of the gate,

for 54” knob height measure up 36

3

/

8

” (925mm).

Place Mounting Bracket ‘A’ on the post as shown, and, using one of the 1” (25mm) wafer-head,

self-drilling screws, fix the bracket to the post – through the side fixing hole. Now install two

more of these screws through the front of the bracket.

3.

To install Mounting Bracket ‘B’ measure up from Bracket ‘A’ 13

3

/

8

” (340mm). Mark this point

and fix as ‘2’ above.

NOTE: For 48” (1220mm) fences without an extra-high post, this measurement should be

5” (125mm) for 54” (1370mm) knob height from bottom of gate.

Place the Bracket ‘B’ so that the holes are centered on the marked line. Fix bracket

using the same screws as per Bracket ‘A’. (NOTE: In some applications it may be

necessary to add a spacer to clear a post cap. Spacers S1, S2 & S3 are for this

purpose and should be inserted behind the mounting brackets during

installation.)

4.

Take the main LATCH BODY ‘C’

and slide it down onto the Mounting

Bracket ‘B’, ensuring the rear track of

the latch slides over brackets ‘B’, then ‘A’.

5.

Slide the Latch Body until the bottom

of the latch aligns neatly with the lower

end of Bracket ‘A’ (see dashed line ‘L’).

Take the single

3

/

8

” (10mm) counter-

sunk screw ‘H’ and secure the Latch

Body – DO NOT use a power or cordless

drill – to Bracket ‘A’.

6.

The final part to be installed is the

STRIKER BODY ‘D’. Note that the Striker

Body slides on a dovetail track within

the Mounting Plate (P1, P2). NEVER use

a powered drill to adjust this screw.

See Diagram ‘E’. Locate the Striker

Body assembly onto the post as shown.

Position the Striker Body to obtain a

1

/

8

” (3mm) gap between the lower part

of the latch and the top of the Striker

Body, as shown. Maintain this gap and

fix two 1” (25mm) screws through the

two main holes of the Striker Body.

The two, small (cylindrical) dress plugs

supplied should now be pressed into the

screw holes.

7.

a

) Open the gate and secure two more screws through the side leg of the Mounting Plate. Note: If the width of the gate

frame is 1

1

/

2

” (38mm) or greater, follow step b)…

b) With the gate open, adjust the Striker Body using the screwdriver in the adjustment screw. Turn counter-clockwise until

the two holes are exposed, as in Diagram (P2). Fix the two remaining screws to secure the Mounting Plate.

8.

Use the screwdriver to adjust the Striker Body to align with the Latch Body, as shown in Diagram ‘E’. Open and close the

gate to check the latch operates correctly. Adjust as necessary at any time after installation to ensure safe operation of the

latch. NOTE: Future vertical adjustment of the latch can be achieved by removing the screw ‘H’, sliding the Latch Body up or

down the post to obtain correct operational alignment, then inserting the screw into the appropriate hole.

Installation Procedure

1.

The gap between gate frame and latch post must be between 10mm (

3

/

8

”) and 37mm (1

7

/

16

”); 19mm (

3

/

4

”) is ideal.

2.

Determine the location of the hole for Mounting Bracket ‘A’ by measuring up 1050mm (41

3

/

8

”) from

the finished ground/fixing surface.

Place Mounting Bracket ‘A’ on the post as shown, and, using one of the 25mm (1”) wafer-head,

self-drilling screws, fix the bracket to the post – through the side fixing hole. Now install two

more of these screws through the front of the bracket.

3.

To install Mounting Bracket ‘B’ measure up from Bracket ‘A’ 340mm (13

3

/

8

”).

Mark this point.

NOTE: For 1220mm (48”) fences without an extra-high post, this measurement should be

125mm (5”).

Place the Bracket ‘B’ so that the holes are centered on the marked line. Fix bracket

using the same screws as per Bracket ‘A’. (NOTE: In some applications it may be

necessary to add a spacer to clear a post cap. Spacers S1, S2 & S3 are for this

purpose and should be inserted behind the mounting brackets during

installation.)

4.

Take the main LATCH BODY ‘C’ and slide it down onto the

Mounting Bracket ‘B’, ensuring the rear track of the latch

slides over brackets ‘B’, then ‘A’.

5.

Slide the Latch Body until the bottom of the

latch aligns neatly with the lower end of

Bracket ‘A’ (see dashed line ‘L’). Take

the single 10mm (

3

/

8

”) countersunk

screw ‘H’ and secure the Latch Body –

DO NOT use a power or cordless drill

– to Bracket ‘A’.

6.

The final part to be installed is

the STRIKER BODY ‘D’. Note that the

Striker Body slides on a dovetail track

within the Mounting Plate (P1, P2) and

is operated by an internal adjustment

screw; NEVER use a powered drill to

adjust this screw.

See Diagram ‘E’. Locate the Striker Body

assembly onto the post as shown. Posi-

tion the Striker Body to obtain a 3mm

(

1

/

8

”) gap between the lower part of

the latch and the top of the Striker Body,

as shown. Maintain this gap and fix two

25mm (1”) screws through the two main

holes of the Striker Body. The two, small

(cylindrical) dress plugs supplied should

now be pressed into the screw holes.

7.

a) Open the gate and secure two

more screws through the side leg of the Mounting Plate. Note: If the width of the gate frame is 38mm (1

1

/

2

”) or greater, follow

step b)…

b) With the gate open, adjust the Striker Body using the screwdriver in the adjustment screw. Turn counter-clockwise until the

two holes are exposed, as in Diagram (P2). Fix the two remaining screws to secure the Mounting Plate.

8.

Use the screwdriver to adjust the Striker Body to align with the Latch Body, as shown in Diagram ‘E’. Open and close the gate

to check the latch operates correctly. Adjust as necessary at any time after installation to ensure safe operation of the latch.

NOTE: Future vertical adjustment of the latch can be achieved by removing the screw ‘H’, sliding the Latch Body up or down the

post to obtain correct operational alignment, then inserting the screw into the appropriate hole.

• Le système Magna Latch peut être utilisé sur les portillons des barrières de protection

de piscines privatives destinées à un usage familial ou collectif.

• Les barrières de protection de piscine sont destinées à limiter lʼaccès de la piscine à des enfants de moins de cinq ans.

• Il est recommandé dʼinstaller la barrière de protection à un mètre minimum du plan dʼeau. Pour les piscines privatives

à usage individuel, il est recommandé de ne pas installer la barrière trop loin du bassin afin de ne pas perdre lʼefficacité

de la barrière.

En matière de barrières de piscine et autres barrières de protection pour les enfants de moins de 5 ans, les normes

de sécurité spécifient entre autres :

1) une barrière d’une hauteur d’au moins 1100 mm (la hauteur minimale entre deux points d’appui doit

toujours être supérieure ou égale à 1100 mm)

2) un système de déverrouillage, en l’occurrence le bouton de déverrouillage, placé à

une hauteur supérieure à 1500 mm à partir du sol à l’extérieur de la zone

protégée.

Par ailleurs, lorsque le moyen d’accès choisi est

pivotant , l’ouverture doit se faire vers

l’extérieur de la piscine. De fait, la

serrure Magna-Latch doit être fixée sur

le côté extérieur de la barrière.

Il est impératif de demander confirma-

tion de ces exigences et d’autres normes

éventuelles auprès des professionnels de

la piscine et des autorités en charge de

l’équipement ou de la sécurité de votre

région et d’installer cette serrure en

parfaite conformité avec les normes et

les réglementations len vigueur.

Outils : perceuse électrique ou sans fil,

mèches, tournevis Phillips No. 2 (manuel

& électrique). Note : pour les mont-

ants en acier de forte épaisseur, il est

conseillé d’effectuer un pré-perçage des

trous, afin d’éviter de briser les vis.

Procédure

d’installation

1. L’écart entre le cadre du portil-

lon et le montant sur lequel sera

placée la serrure doit être compris

entre 10 mm et 37 mm, la distance

idéale étant de 19 mm.

2. Marquer lʼemplacement du trou

nécessaire au montage de la patte

de fixation A à 1100 mm du sol fini

ou de la surface de fixation.

Visser la patte de fixation A sur

le côté du montant de la barrière

comme indiqué sur le schéma, à l’aide de l’une des vis autoperforantes à tête wafer 25 mm. Finir de fixer

la patte de fixation à l’aide de deux autres vis semblables sur la face avant du montant.

3. Pour installer la patte de fixation B, tracer une ligne à 125 mm au-dessus de la patte de fixation A

(prendre pour repère la vis centrale de la patte de fixation A).

Positionner la patte de fixation B de manière à ce que les

trous soient centrés sur la ligne tracée, puis la fixer à l’aide du même type de vis que pour la patte de

HIGH POST

used in some

markets

MLINSTR0029PA

AUSTRALIA: Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731 Woodwind Drive, Huntington Beach, CA 92647

EUROPE: Niasstraat 1, 3531 WR Utrecht, The Netherlands.

www.ddtechglobal.com

ENGLISH – International

ENGLISH – North America

•INSTR MLTP North America 29/11/12

F R A N ÇAIS – Canada

NOTICE DE MONTAGE