D&D Technologies SureClose Flush Mount Screw-On User Manual

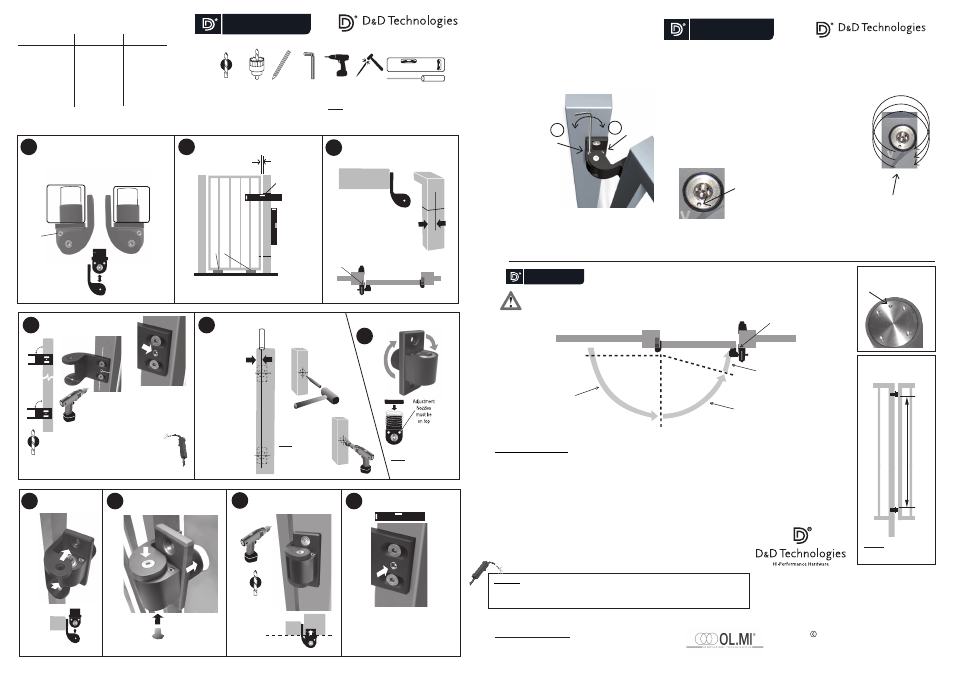

Flush mount models - screw-on, Close, Installation instructions

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

FLUSH MOUNT MODELS - SCREW-ON

GA

TE

F

RA

ME

FE

NC

E

PO

ST

GA

TE

GA

TE

GA

TE

90˚

90˚

Flush Mount Models

Hole diameter

Min Post Size

SM AT90 S 1

9

/

16

” (40mm) 2” (50mm)

57 AT90 S

1

9

/

16

” (40mm) 2” (50mm)

57SF AT90 S

1

9

/

16

” (40mm) 2” (50mm)

108 AT90 S

1

9

/

16

” (40mm) 3” (75mm)

108SF AT90 S

1

9

/

16

” (40mm) 3” (75mm)

NOTE: If using SM hinge, always install at bottom of

gate. 57 and 108 models should be installed on top.

Use #14 countersunk fasteners.

3, 4, 5mm

1

9

/

16

”

(40mm)

18V

Laser level

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

DETERMINE THE HANDING

Adjustment

Nozzles

must be

on top

Hinged from the left

Fence Post

Hinged from the right

Fence Post

Remove

Gate Bracket

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

Mark hinge center lines

MARKING HEIGHTS

GAP:

5

/

16

”-

1

/

2

”

(8-13mm)

Support Blocks

Ensure post is vertical in the

front and side elevations

MARK HINGE BRACKET LOCATION

ON GATE FRAME

Mark center lines as

guides for fastening

Brackets onto the

Gate Frame

1” (25mm)

FASTEN, CENTERED ON SET SCREW

A) Back out set screw and install two

main fasteners. FIRMLY TIGHTEN.

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

MARK TOP AND BOTTOM BRACKETS ON POST

Ensure drill hole will

clear the post wall

thickness.

7

/

8

”-1

1

/

16

”

(22-27mm)

Laser Level

F E N C E P O S T

G AT E

90˚

90˚

F E N C E P O S T

F E N C E P O S T

Drill 1

9

/

16

” (40mm)

holes top and bottom

NOTE: Apply corrosion

protection to exposed

metal surfaces.

SCREW POST BRACKET ONTO HINGE

ASSEMBLE HINGE TO

BRACKETS ON GATE

G AT E F R A M E

F E N C E P O S T

G AT E

G AT E

G AT E

90˚

90˚

GA

TE

F

RA

ME

FE

NC

E

PO

ST

GA

TE

GA

TE

GA

TE

90˚

90˚

REPLACE HINGE PINS AND INSERT

INTO POST

FASTEN BRACKETS

TO FENCE POST

1

2

3

4

5

6

7

8

9

10

SET SCREW

Ensure face and side of gate are level. Firmly

tighten two main fasteners before tightening

set screw.

SURE

Close

®

Hi-Performance Hardware

Installation Instructions

B) Once bracket is at

desired position, firmly

tighten the set screw.

3/16” (5mm)

Flush Mount:

Face of gate and post

are aligned.

3/16” (5mm)

3

/

16

”

(5mm)

Pencil

NOTE: Apply grease to hinge

threads to prevent water

from entering post.

Level

(V)

+

–

(S)

ADJUSTING THE CLOSING SPEED

AND FINAL ‘SNAP’ ACTION (108 ONLY)

SURE

Close

®

Installation Instructions

Hi-Performance Hardware

CAUTION: Sensitive adjustment, rotate MAX

1

/

4

turn at a time.

V=Closing Speed

S=Final Snap Action

Turn nozzles clockwise to decrease speed & counterclockwise to

increase speed.

IMPORTANT:

Use dimple to determine how far nozzle has turned.

DO NOT turn adjustment nozzles more than 3 complete rotations.

DO NOT unscrew nozzle past the surface of the body.

CAUTION:

DO NOT remove adjustment nozzles or disassemble hinge.

Doing so voids warranty.

If using a 57+57 or 108+108 combination, each closer must

have equal closing speed at all times.

Models 57SF & 108SF

open to and self-close from 90

o

.

NO hold-open feature.

*

Suitable for child/pool safety gate.

DO NOT PROP GATE OPEN.

Models 57 & 108

open 180

o.

Hold-open from

180

o

to 90

o

. Self-close

from 85

o

to 0

o

NOT for child/pool safety gate.

Models 108 and 108SF

have Final Snap Action.

Flush Mount

Face of gate and

post are aligned

Use flush mount latches/locks.

SCOLM000015PA 10/2/14

MAINTENANCE REQUIREMENTS

• Gate stop must be installed when using SF models. Gate must not be allowed to open past 90

˚

.

Doing so voids warranty.

• Never use more than two (2) SureClose hinge/closers on any one gate.

• Remove all other types of hinges and self-closing devices.

• Always install SM hinge at bottom of gate and 57 or 108 closer on top.

• Ensure the gate does not swing through the line of the fence. Use a “gate stop” or a latch (with striker)

to prevent this.

• All steel mounting brackets (gate and post) should be painted or powder coated. Spray painting is recommended.

• The anodized aluminum mounting brackets do not need finishing, but they may be painted or powder coated.

• DO NOT powder coat the hinge/closer, but they may be painted.

• DO NOT turn the adjustment nozzles more than two (2) full rotations.

• DO NOT unscrew nozzle past the surface of the body.

• DO NOT remove the adjustment nozzles or disassemble these hinges at any time. Doing so voids warranty.

• Ensure the hinges are kept free of sand, ice and other debris that could impair effective operation.

*

CAUTION: When used on swimming

pool gates, always consult local

authorities for swimming pool Codes.

SF models have 5 dimples

for identification

SURE

Close

®

Flush Mount Screw-On

Distance between hinges 35

1

/

2

” (900mm) minimum

v

Swimming Pool Gates

AU/NZ

v

For Swimming

Pool Gates

in AU/NZ

(see Page 2)

AUSTRALIA: Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731 Woodwind Drive, Huntington Beach, CA 92647

www.ddtechglobal.com

2 YEAR LIMITED WARRANTY:

For a downloadable Adobe Acrobat (.PDF) version of our 2 YEAR LIMITED WARRANTY,

go to our website at www.ddtechglobal.com

CAUTION: Overheating any SureClose product during welding may cause failure and will void

warranty. To ensure threads on mounting bracket are not deformed, weld one surface at a time and alternate

between top and bottom hinge. Finish with appropriate corrosion protection, avoiding thread contamination.

For welding installations, general field welding

operations with suit able heat transfer controls,

clean up and rust protection procedures should

be followed.

See

CAUTION advice on next page.

Copyright 2012 D&D Group Pty Ltd, Sydney Australia

Patented: CA 2650769; US 7900319; NZ 573211;

AU2010280342, AU2011202070

Gate stop must be installed when using SF models.

Gate must not be allowed to open past 90

˚

. Doing so

voids warranty.

MANUFACTURED BY OL.MI

PRECISION ENGINEERING