D&D Technologies TruClose Regular Round Post User Manual

Step 1 – install 4 mounting brackets, Installation instructions, Step 4 adjust tension

Step 4

ADJUST TENSION

Remove endcap. While support-

ing the weight of the gate, use

the large screwdriver to depress

and turn the spring-loaded

adjustor counter-clockwise. Hold

the desired tension and allow the

adjustor to rise back into reten-

tion sleeve. Replace endcap.

TCAMA1RND:

TCAMA1RND2:

TCAMA2RND:

TCAMA2RND2:

GATE: 1

3

/

8

" (35mm)

2" (50mm)

1

3

/

8

" (35mm)

2" (50mm)

POST: 2"(50mm), 2

3

/

8

"(60mm), 2

7

/

8

"(73mm) 2"(50mm), 2

3

/

8

"(60mm), 2

7

/

8

"(73mm)

2"(50mm), 2

3

/

8

"(60mm), 2

7

/

8

"(73mm) 2"(50mm), 2

3

/

8

"(60mm), 2

7

/

8

"(73mm)

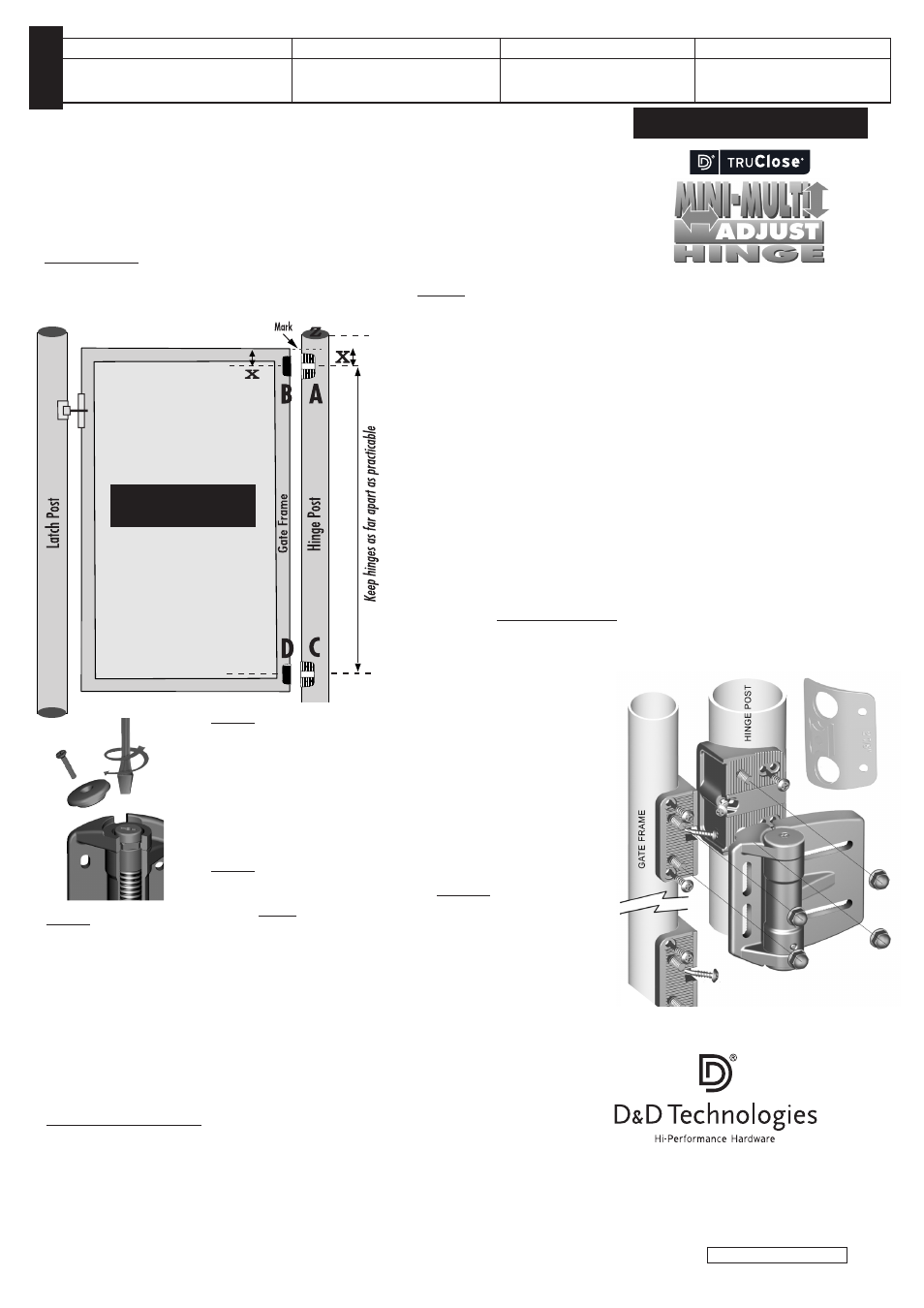

Some important points concerning the installation of MULTI-ADJUST HINGES:

• The hinges should be installed as far apart as is practicable for optimum performance.

• Minimum gap between hinge post and gate:

3

/

4

" (19mm).

• Maximum gap: TCAMA1RND: 1

1

/

2

" (39mm), TCAMA2RND: 2

1

/

16

" (53mm).

TCAMA1RND2: 1

1

/

2

" (39mm), TCAMA2RND2: 2

1

/

16

" (53mm).

Tools required: Electric drill/cordless drill (use low clutch settings), drill bits, Phillips No. 2

screwdriver (hand & power), large slot-head screwdriver and

7

/

16

" wrench (preferably 6" long (150mm).

Step 1 – Install 4 MOUNTING BRACKETS

For centering and leveling Brackets A and B (and C & D), align the center of each

bracket with centerlines as indicated by the dashed lines.

1.

Determine the location of the gate in the mounted position. On the hinge post,

mark the top of the gate, as shown at point ‘Z’.

2.

From this point, measure down the desired distance [X] for the center of the

Brackets A and B – and up the same distance from the bottom of the gate for

Brackets D and C. (Note that the top of the smaller brackets B and D should

never

be installed closer than 1

3

/

16

" (30mm) from the top or bottom of the gate respec-

tively.)

3.

Using the 1

1

/

4

"x10g self-drilling, wafer-head screws supplied, first (for a R-H

hinged gate as shown) fix Brackets B and D to the gate frame, and then fix Brack-

ets A and C to the hinging post. (For a L-H hinged gate fit A & C to the post and

B & D to the gate. Ensure enough clearance at the bottom (D-C) to allow for easy

adjustment, as adjustor is facing down.)

Each Bracket has three screw holes: two at the front and one in the side-fixing leg.

If a vinyl gate has aluminum reinforcing thicker than

1

/

8

" (3mm), or steel of any

thickness, the screws will require

5

/

32

" (4mm) ‘pilot’ holes.

▼

MAINTENANCE & REQUIREMENTS:

• Always use two MULTI-ADJUST hinges on any one gate.

• Ensure the gate does not swing beyond 180˚.

• Each hinge must have equal tension at all times.

• Remove all other types of hinges and self-closing devices.

• Do not lubricate or disassemble these hinges at any time.

• Never remove MULTI-ADJUST hinges from gate until spring tension is released.

• Do not physically alter hinge bodies by cutting, milling, machining or grinding any part.

• For safety, remove protruding bolts/screws after installation by cutting, grinding and/or filing.

•INSTRUCTS TCA4-5 14/12/11

TCAMARND000PA

suits

both

right

-

hand

or

left

-

hand

hinged

gates

Example of R-H hinged gate

Example of R-H hinged gate

INSTALLATION INSTRUCTIONS

TO FIT

ROUND POSTS:

Step 2 – Install MAIN HINGE BODY

1.

Take the hinge bodies and place them over the gate Brackets B and D.

Use the dome nuts supplied to secure the hinges finger tight.

2.

Have the remaining dome nuts at hand. Take the gate (with hinges

attached) and locate the hinges over the post Brackets A and C. Secure

the dome nuts to temporarily fix the gate into position.

Step 3 – VERTICAL & HORIZONTAL ADJUSTMENT

1.

Note that the slots on the right leaf are horizontal and on the left leaf

they are vertical. The gate now needs to be lifted and aligned for correct

operation. Lift gate so that the top of the gate is in line with point ‘Z’.

Firmly tighten the dome nuts on the left-hand leaf.

DO NOT

OVERTIGHTEN THE DOME NUTS – thus the suggested 6" wrench.

2.

The horizontal slots in the right-hand leaf provide an adjustment range of

TCAMA1RND, TCAMA2RND:

3

/

4

" (19mm), TCAMA1RND2, TCAMA2RND2: 1

5

/

16

" (33mm).

Use this range to adjust the hinge gap to the desired position. Fix this position

by firmly securing all the remaining dome nuts using the 6" wrench.

Minor alignment adjustments may be required from time to time.

AUSTRALIA: Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731 Woodwind Drive, Huntington Beach, CA 92647

EUROPE: Niasstraat 1, 3531 WR Utrecht, The Netherlands.

www.ddtechglobal.com

For a downloadable Adobe Acrobat (.PDF) version of our Limited LIFETIME WARRANTY,

go to our website at www.ddtechglobal.com