Communication Concepts AN762 Application Note User Manual

Page 7

AR

C

HIVE INF

O

RMA

TI

O

N

PRODUCT TRANSFERRED T

O

M/A

–

COM

AN762

7

RF Application Reports

This number can be used to select a suitable heat sink

for the amplifier. The information is given by most

manufacturers for their standard heat sinks, or specific

lengths of extrusion. As an example, a 9.1

″ length of

thermalloy 6153 or a 7.6

″ length of Aavid Engineering 60140

extrusion would be required for 100% duty cycle, unless the

air velocity is increased by a fan or other means.

PERFORMANCE AND MEASUREMENTS

The performance of each amplifier was measured with

equipment similar to what is described in reference

(2)

. The

solid lines in Figures 6, 7, 8 and 9 represent the 100 W unit,

the dashed lines represent the 140 W unit, and the dotted

lines refer to the 180 W version. The data presented is

typical, and spreads in the transistor h

FE

’s will result in slight

variations in RF power gain (Figure 7).

The performance data is also affected by the purity of the

driving source. There should be at least 5 – 6 dB IMD margin

to the expected power amplifier specification, and a harmonic

suppression of 50 dB minimum below the fundamental is

recommended

(7)

.

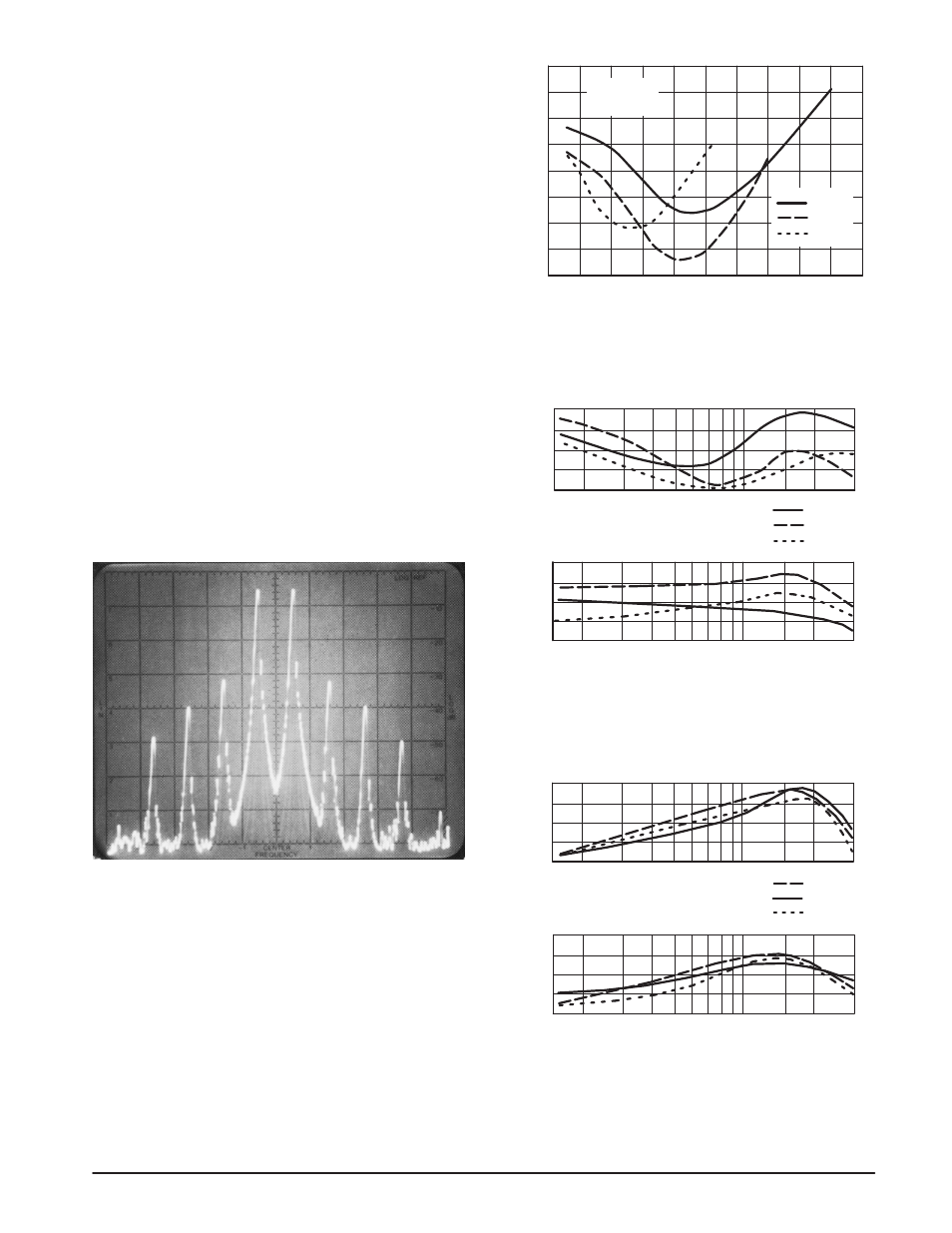

The IMD measurements were done in accordance to the

E.l.A. proposed standard, commonly employed in Ham Radio

and other commercial equipment design. The distortion

products are referenced to the peak power, and adjusting

the tone peaks 6 dB below the 0 dB line on the spectrum

analyzer screen (Figure 5) provides a direct reading on the

scale.

Figure 5. An Example of the IMD Spectral Display

(c. Power Output = 180 W PEP, 30.00 MHz)

The Two Tones Have Been Adjusted 6 dB Below the Top

Line, and the Distortion Products Relative to Peak Power

can be Directly Read on the Scale.

The collector efficiency under two tone test condtions is

normally 15 – 20% lower than at CW. The load line has been

optimized for the peak power (as well as possible in a

broadband system with transformer impedance ratios of 4:1,

9:1, 16:1, 25:1, etc. available), which at SSB represents a

smaller duty cycle, and the power output varies between zero

and maximum. Typical figures are 40 – 45% and 55 – 65%

respectively.

POWER OUTPUT (WATTS, PEP)

IMD (dB)

- 30

0

40

80

120

160

200

- 35

- 40

- 45

- 50

180 W

140 W

100 W

c

a

b

f = 30.0 MHz

V

CC

= 13.6 V

Figure 6. Intermodulation Distortion versus

Power Output

FREQUENCY (MHz)

INTERMODULA

TION

- 30

1.5 2.0

3.0

5.0

10

30

- 35

- 40

16

15

180 W

140 W

100 W

V

CC

= 13.6 V

14

13

12

7.0

15

20

a

c

b

a

c

b

POWER GAIN (dB)

DIST

OR

TION (dB)

Figure 7. IMD and Power Gain versus Frequency

FREQUENCY (MHz)

COLLECT

OR EFFICIENC

Y

50

1.5 2.0

3.0

5.0

10

30

45

40

2.00

180 W

140 W

100 W

V

CC

= 13.6 V (TWO TONE TEST)

1.50

1.00

7.0

15

20

a

c

b

a

c

b

INPUT

VSWR

(%)

Figure 8. Input VSWR and Collector Efficiency

versus Frequency