Archive informa tion archive informa tion – Communication Concepts EB27A Engineering Bulletin User Manual

Page 2

ARCHIVE INFORMA

TION

ARCHIVE INFORMA

TION

EB27A

2

RF Application Reports

Transformer Construction

For continuous operation at full power CW, it is

recommended that heat sink compound, such as Dow

Corning #340, be applied between the board surface and

R

3

and R

4

, and if possible have air circulating over the top

of the circuit board as well.

The effective base-to-base impedance, increased by the

RC networks is about 5 ohms at midband. As a result of

this and the 9:1 impedance ratio in the input transformer T1,

the input VSWR is limited to 1.9:1 or less across the band.

Transformer T2, in addition to providing a source for the

feedback and carrying the dc collector current, acts as the

rf center tap of the output transformer. To construct T2, wind

5 turns of 2 twisted pairs of AWG No. 22 enameled wire on

a Stackpole 57-9322 toroid (Indiana General F627-8Q1).

V

CC

= 28 V

P

OUT

= 300 W PEP

η

(%)

(DOTTED)

50

40

30

FREQUENCY (MHz)

30

20

15

10

7

1.5 2

3

5

POWER GAIN (dB)

VSWR (SOLID) 1

2

3

10

11

12

13

14

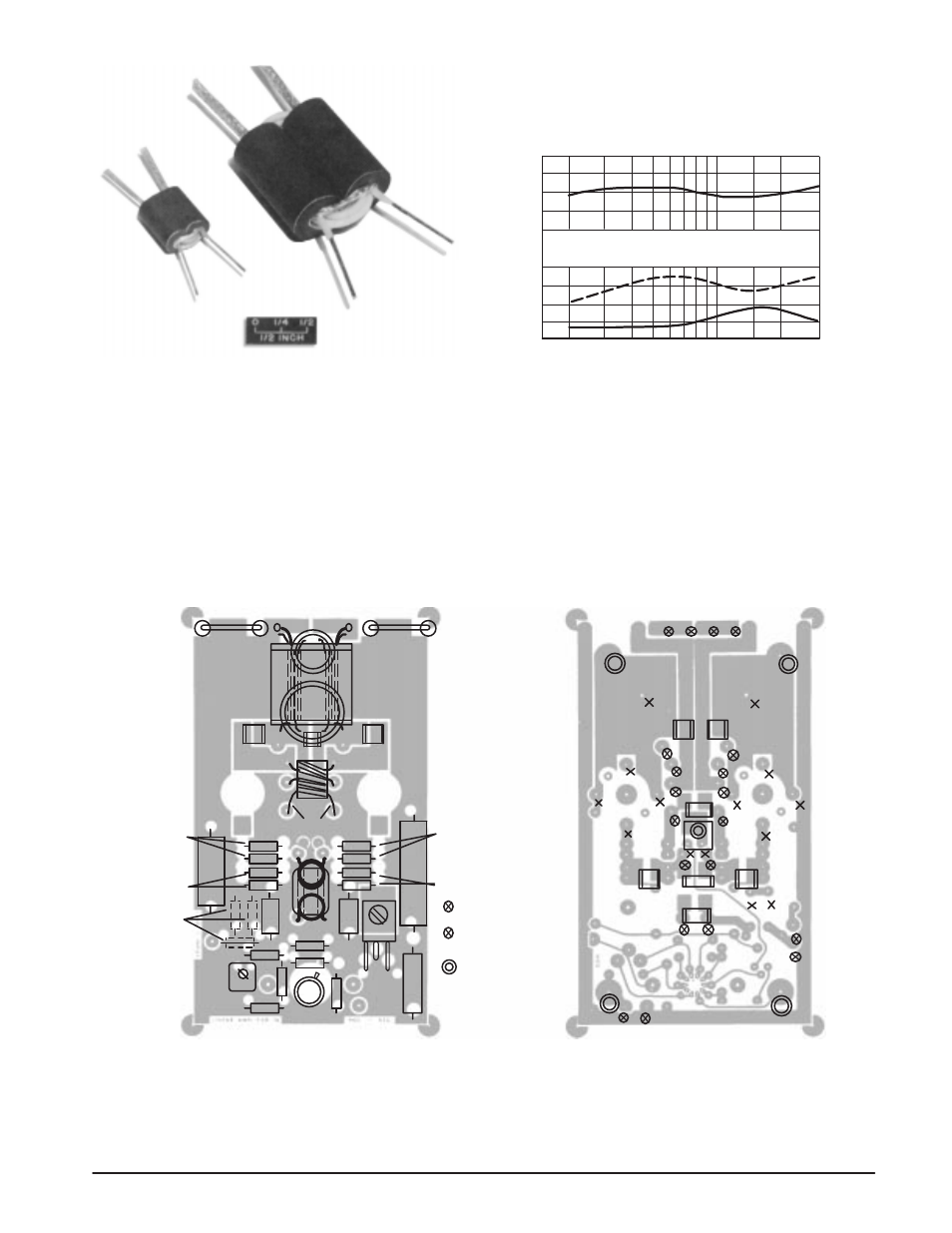

Figure 1. Collector Efficiency,

Power Gain and VSWR vs Frequencv

A Stackpole dual balun ferrite core 57-1845-24B is used

for T1. The secondary is made of 1/8

″

copper braid, through

which three turns of the primary winding (No. 22 Teflon

insulated hook-up wire) are threaded. The construction of

T3 is similar to that of T1. It employs two Stackpole 57-3238*

ferrite sleeves which are cemented together for easier

construction. The primary is made of 1/4

″

copper braid,

through which three turns of No. 16 Teflon

insulated wire

are threaded for the secondary .

A.

B.

C4

Optional

Input

Atten-

uator

R10 MC1723C

C2

C11

C1

D1

C3

C13

C12

Q1

Q2

C

C

T2

E

E

E

E

C5

C7

C6

L4

L3

L5

R4

R2

C15

R5

R3

R1

C14

L1

L2

T1

R6

C16

R11

R7

R9

R8

Q3

= Terminal Pins and

Feedthroughs

= Feedthrough

=

Eyelets.

= Stand Off’s