Split function, Unbalance resolution), 4 split function (unbalance resolution) – CEMB USA C71_2 SE evo (B) User Manual

Page 13

13

1

2

1

2

1

2

2

1

2

1

2

1

Use and maintenance manual Rev. 10-2012

ENGLISH

▪ Fit the correction weight in the specific gauge seat with

the adhesive part facing upwards

▪ Bring the wheel into correct angular position for the

plane to be corrected

▪ If the wheel clamp option is enabled (see

MENU

),the wheel

is automatically clamped in the correction position.

▪ withdraw the gauge until the correction plane indication

arrows turn green

▪ If the buzzer is enabled (see

MENU

), the attainment

of the weight application distance is accompanied by

a beep.

▪ Rotate the gauge until the correction weight adheres to

the rim

▪ the fact that the weight application position is no longer

vertical is automatically compensated.

- INSIDE CORRECTION POSITION

- OUTSIDE CORRECTION POSITION

To cancel the function, press the

button again.

5.4

SPLIT FUNCTION

(unbalance resolution)

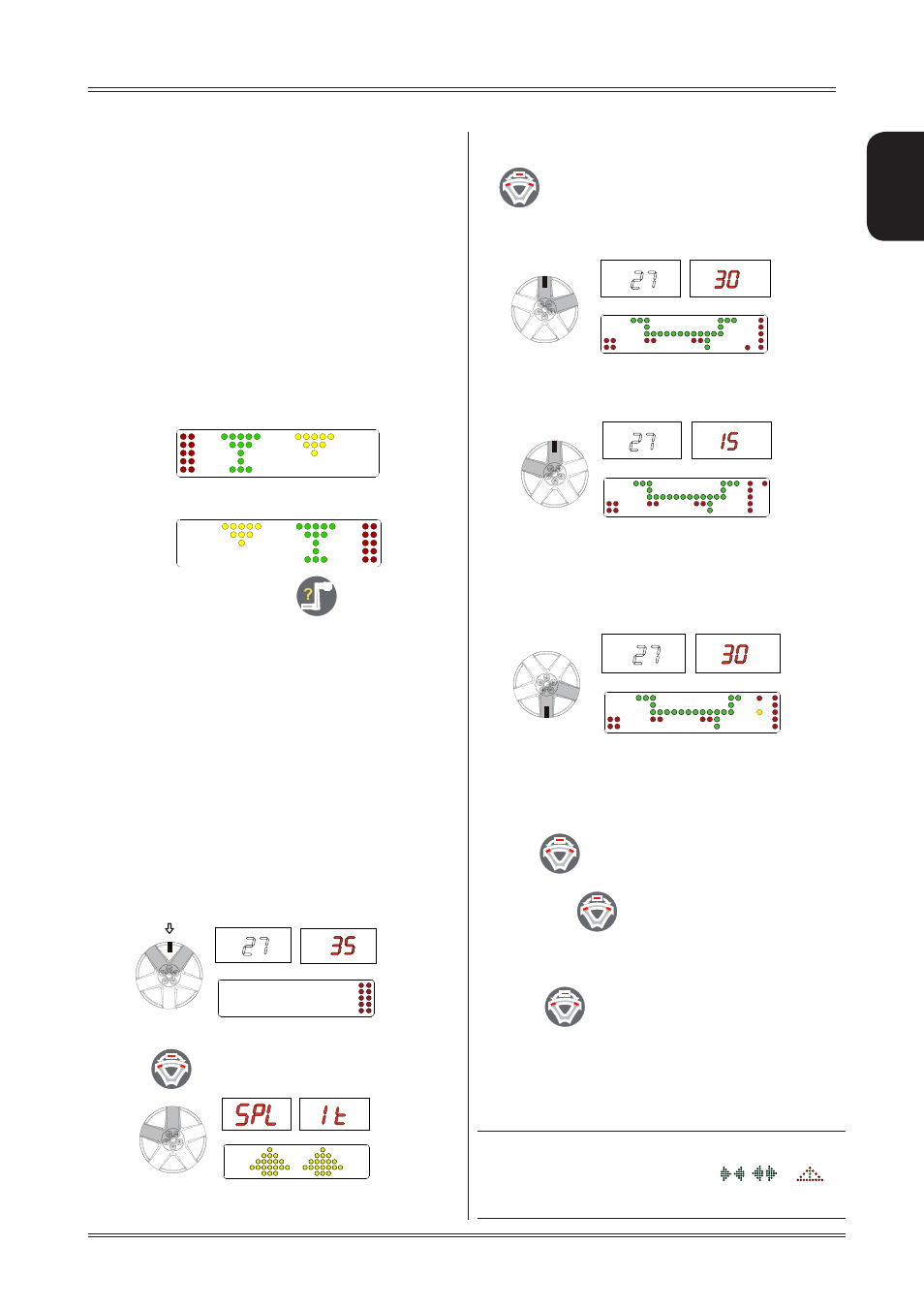

The SPLIT function is used to position the adhesive weights

behind the wheel spokes (angle > 18°) so that they are no

longer visible (for alloy rims). Use this function in the ALU

or STATIC mode where the adhesive weight is applied to

the outer side of the rim.

Enter the wheel dimensions in the ALU S mode and press

START.

If LSr option = OFF

a. Turn the wheel to the outer side unbalance correction

position.

b. Move one of the spokes to 12 o’clock (e.g.: 1) and

press

c. Following the direction of rotation indicated by the

position LED’s, move spoke 2 to12 o’clock and press

. The value to use for correction in position 2

is displayed.

d. Move spoke 1 to the correction position as indicated

by the position LED’s

Only standard version

If the “OPPOSITE POSITION” function is enabled (see the

relative paragraph), the bottom correction position (at 6

o’clock) is indicated by the central LED coming on for each

phase column.

Only SE version

If LSr option = ON

▪ Position the static unbalance or outside ALUS in the

in the correction position:

▪ press

and hold down until the laser points

to the spoke where you want to correct

▪ release the

button

▪ turn the wheel in the unbalance rotation direction

indicated on the display until the second spoke is in

the position indicated by the laser and press the

button

▪ position the wheel as indicated by the LEDs. The un-

balance is indicated on the display.

To return to the normal unbalance indication press any

button.

INfoRmATIoN

The spoke-to-spoke distance must be a minimum of 18°

and a maximum of 120° (if not, errors

,

or

appear). Spokes with irregular or inconstant angles can

be compensated.

Use of the wheel balancer