5 when and why matching – CEMB USA C218 User Manual User Manual

Page 14

14

Use and maintenance manual Rev. 04-2011

ENGLISH

5.5

WHEN AND WHY MATCHING

The software associated with eccentricity measurement is

a powerful tool for determining the need to perform relative

rotation between the rim and tyre in order to reduce the eccen-

tricity of the wheel down to acceptable limits. The principle

adopted is based on the consideration that a rim with acceptable

tolerance, mounted with an acceptable tyre, can statistically

generate a total eccentricity which is not acceptable but can

be improved by matching.

Generally speaking, rim measurement is not necessary,

accurate or useful because:

To measure the rim it is necessary to remove the tyre.

▪

There can by coarse errors on the outside (e.g. alumi-

nium wheels!)

The two rim sides can be eccentric in a very different

▪

way. Therefore to which one to make reference? What

is the effect on the tyre mounted?

To improve the eccentricity of a wheel,

▪

the rim should be

eccentric, to compensate the tyre. And viceversa.

If after a rotation by 180° of a wheel, the value is still

▪

out-of-tolerance, either the tyre or rim are too eccentric:

One of the two must be replaced!

SOLUTION: Rotate the tyre on the rim by 180°

RESULT: wheel eccentricity 0.3 - 0.4 mm (in tolerance)

wheel

rim

tyre

rotation axle

Ideal wheel

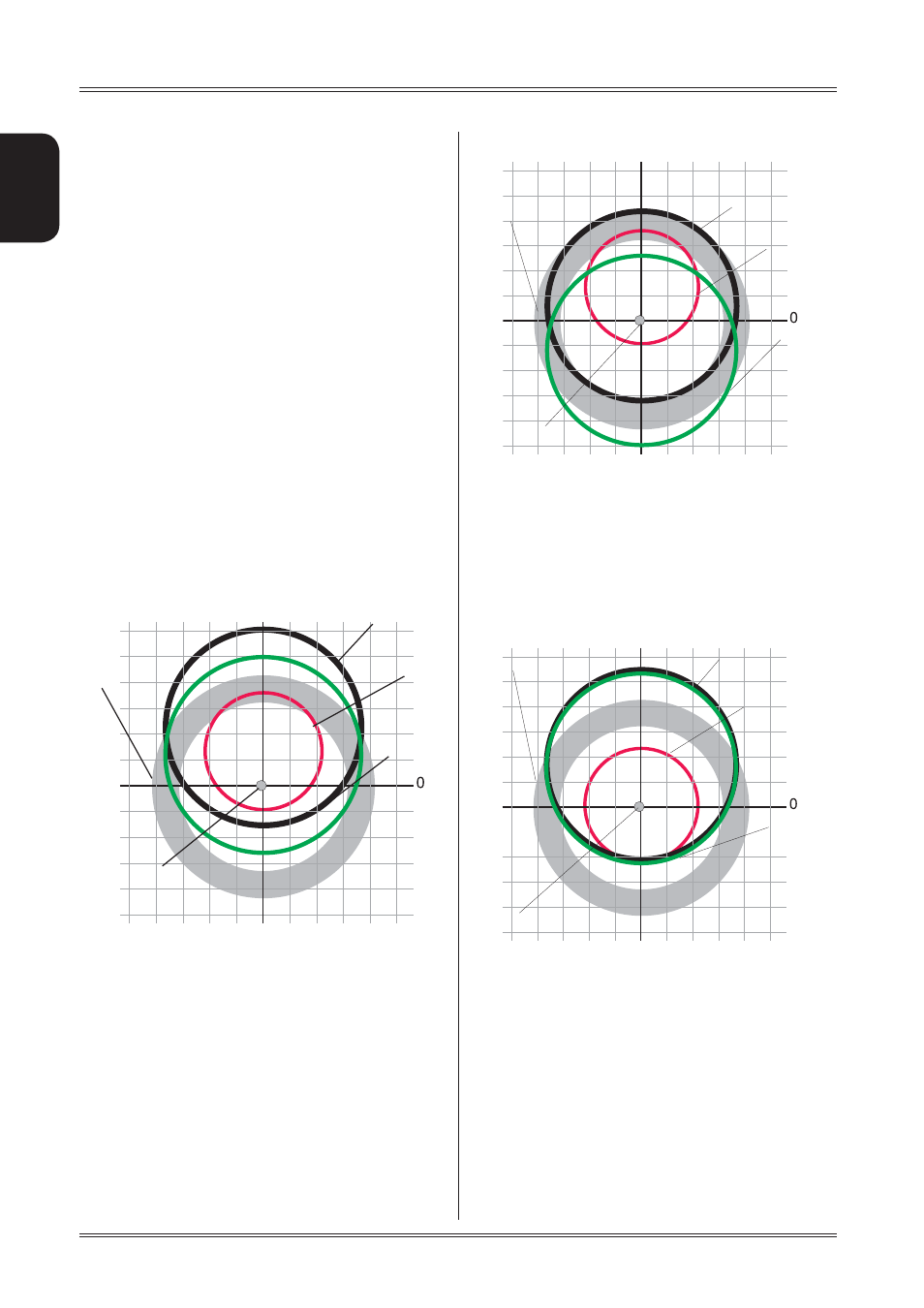

Example 1

Rim + 0.8 mm

Tyre + 0.6 mm

Wheel + 1.3 mm

Eccentricity of the wheel is excessive, due to an acceptable

rim or tyre but randomly placed in an “unfortunate” relative

position.

SOLUTION: Rotate the tyre on the rim by 180°

RESULT: no improvement is obtained.

Example 2

Rim + 0.8 mm

Tyre - 0.6 mm

Wheel + 0.3 mm

Eccentricity of the single items has been compensated.

The wheel is acceptable.

Example 3

Rim 0 mm

Tyre + 1.2 mm

Wheel + 1,2 mm

Eccentricity of the wheel cannot be compensated by the

rotation because the rim is perfect!

wheel

rim

tyre

rotation axle

Ideal wheel

Use of the wheel balancer

wheel

rim

tyre

rotation axle

Ideal wheel