Figure 16 – sequence of cycle on demand operation – DE-STA-CO VARI-PAK DC CONTROL User Manual

Page 17

15

VIII. APPLICATION WIRING DIAGRAMS (Reversible Models)

P/N 92A61633020000 (120 VAC) – P/N 92A61633040000 (240 VAC).

Reversing models carry out the same functions as the unidirectional models except they can

be made to index in both the forward and reverse direction. A special circuit APRM® pro-

vides a lockout feature that prevents catastrophic damage to the drive if a “Reverse” com-

mand is given during “Forward” operation (and vice versa). The reversing drives contain two

additional positions on the terminal block: “Run Rev” and “Jog Rev.” The stop logic com-

mand is made with a normally closed (NC) contact.

Note: The sense of the stop logic can be changed from normally closed (NC) to nor-

mally open (NO) by placing jumper JS in the “NO” position.

The wiring diagrams on page 16 illustrate typical logic circuits. Many other configurations are

possible. Consult factory if help is needed.

IX. OPERATION

WARNING! Read Safety Warning on page 2 before attempting to operate the

control or severe injury or death can result. Failure to follow the Safety

Warning Instructions may result in electric shock, fire or explosion.

ROTATION

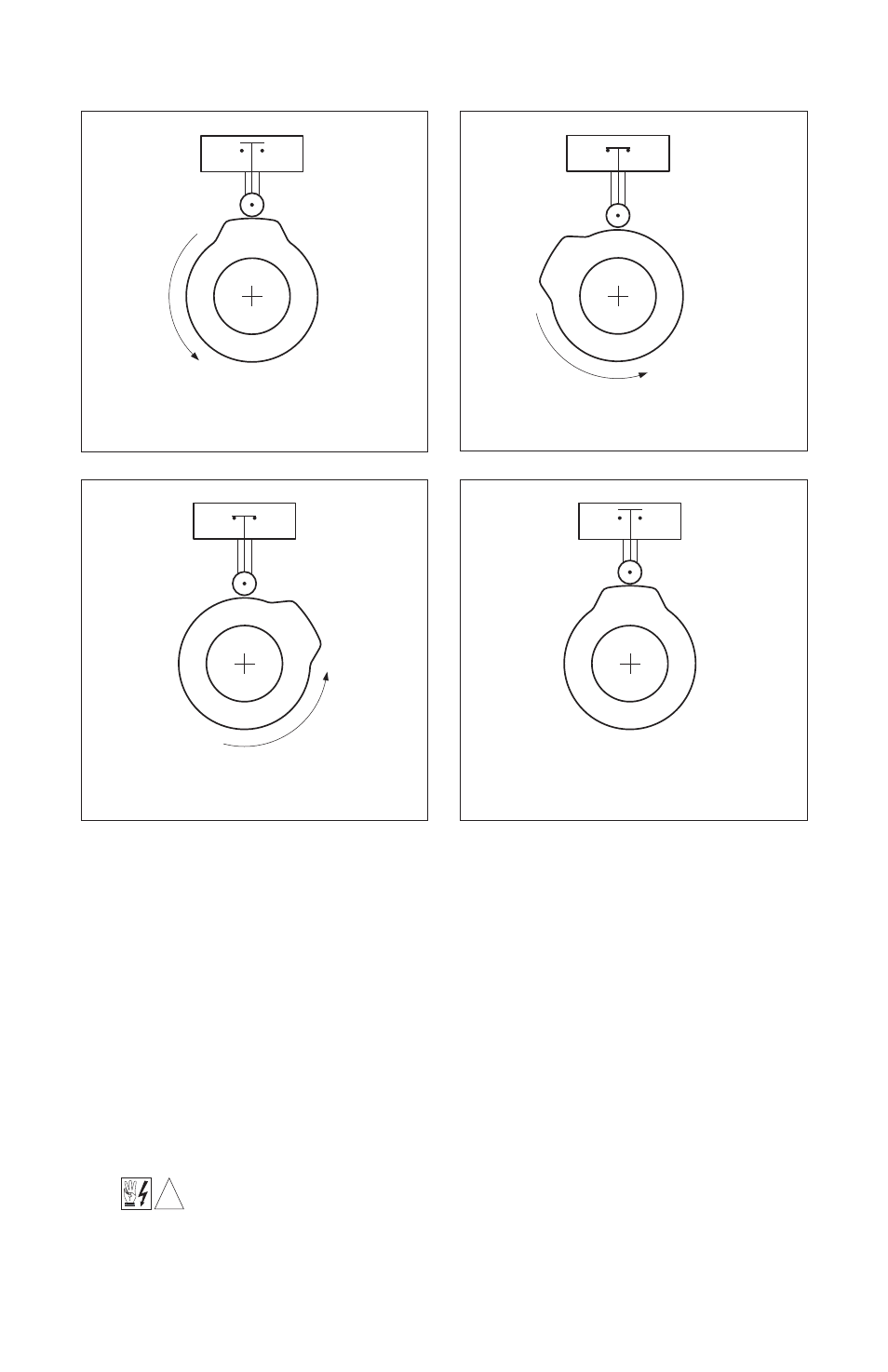

OF CAM

CONTACT IS OPENING

LS1

LS1

CONTACT CLOSES

1) CLOSE START BUTTON TO INITIATE

CYCLE (MOMENTARY CLOSURE)

2) CAM ROTATES, LS1 CONTACT CLOSES

CLOSED

CONTACT REMAINS

LS1

LS1

CONTACT OPENS

1) CAM CONTINUES TO ROTATE THROUGH

CYCLE, LS1 REMAINS CLOSED

4) CAM ROTATES UNTIL LOBE UNTIL LS1 CONTACT,

DRIVE BRAKES TO A STOP. CLOSE MOMENTARY

START BUTTON TO INITIATE NEW CYCLE.

FIGURE 16 – SEQUENCE OF CYCLE ON DEMAND OPERATION

!