DE-STA-CO VARI-PAK DC CONTROL User Manual

Page 15

13

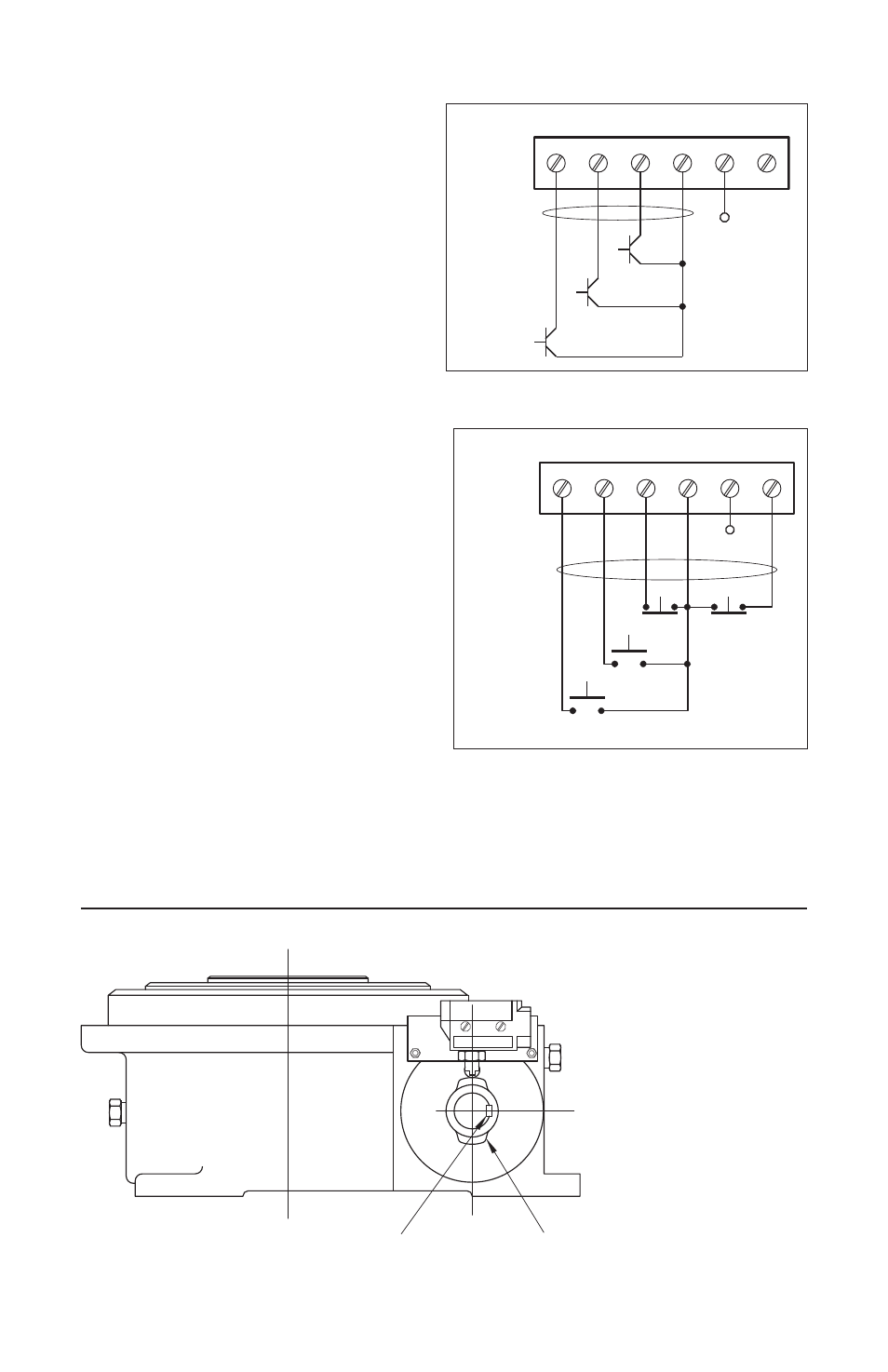

Capable of switching 30 VDC, at 24 mA,

with an off-state leakage current of less

than 1 mA. (See figure 12.) Warning!

Do not ground or short +24V to COM or

return on TB1. Do not use +24V for

other than open collector sensors. (See

figure 12.)

Example 2: For optimum operation,

contacts used on logic inputs should be

rated for low-level logic switching (i.e.

gold contacts). (See figure13.)

Example 3:

“Cycle on Demand” –

Important Information

In a “Cycle on Demand” application, the

CAMCO Index Drive will make one com-

plete cycle of movement of table or con-

veyor and then dwell until it receives an

external signal from the machine’s con-

troller or operator to start again. If motor

receives a signal to start while the CAMCO

Index Drive is in its dwell position, the

motor will accelerate from a paused posi-

tion to full speed during one half of the

dwell of the main index cam. When the

motor has reached its maximum speed

and is no longer accelerating, the motion of

the CAMCO Index Drive can start. As the

Indexer re-enters its dwell portion of the

main cam, the signal cam located on the

camshaft of the CAMCO Index Drive will

actuate the limit switch to signal a stop.

(Note: Due to time delays, the signal cam

may have to signal a stop some degrees

before the index drive actually enters the dwell.) It is important that the motor is made to stop

while in the dwell of the main cam. Stopping in any other position could damage the control or

the Index Drive! Read all the instructions carefully in order to familiarize yourself with your new

CAMCO Index Drive. (See figures 14A, 14B and 14C.)

RUN

JOG

STP

RTN

+24V COM

NOTE: JUMPER

"JR" MUST

STOP

JOG

START

BE IN THE

"F" POSITION

+V

See section IV,

items 1-4,

on page 9

FIGURE 12 – SOLID STATE SWITCHING

RUN

JOG

STP

RTN +24V

COM

NOTE: JUMPER

"JR" MUST

BE IN THE

"O" POSITION

RTN

STOP

JOG

START

+V

See section IV,

items 1-4,

on page 9

FIGURE 13 – CONTACT SWITCHING

Type II Extra

CAM LOBE

Keyway

A standard Roller Gear unit

with the CAM & Limit Switch

mounted on the correct key-

way position directly opposite

of the output shaft, 90º (clock-

wise) from the CAM Lobe.

The CAM & Limit Switch may

also be mounted on the

reducer. If the unit has a

“Type II” motion, a special

Limit Switch CAM is needed

with one extra Lobe, 180º

from the first Lobe (as shown).

Note: On some RDM units

(such as the 601 RDM), the

CAM & Limit Switch is

mounted at an angle.

FIGURE 14 – CORRECT KEYWAY POSITION FOR CAM & LIMIT SWITCH ASSEMBLIES

FIGURE 14A – ROLLER GEAR UNIT