DE-STA-CO VARI-PAK DC CONTROL User Manual

Page 16

14

The “Cycle on Demand” function is

required for most indexing table applica-

tions. The control can be easily set for

this operation as follows:

1. Jumper “JW” must be in the “R” posi-

tion (factory setting) see table 6, on

page 12.

2. Jumper “JR” must be in the “F” posi-

tion (factory setting) see section VI D,

on page 11.

3. Wire limit switch LS1 (normally closed)

and start switch (normally open) as

shown.

The “Cycle on Demand Operation”

begins with limit switch LS1 riding on the

CAM lobe. (Since LS1 is a normally

closed switch, it will be open when riding

on the lobe.) The cycle is initiated by

momentarily closing the start switch. The

drive will start even though LS1 is open.

(Jumper JW is in the “R” position giving priority to the start switch which overrides the

stop.) As the camshaft rotates, it moves off LS1 which closes. When the lobe rotates

around back to LS1, LS1 now opens and the drive stops. The drive is now ready to repeat

the cycle by initiating another start command. See figure 16, on page 15.

Note: A normally open (NO) STOP contact can also be used. To convert to a normal-

ly open STOP, move jumper JS from the factory position “NC” to position “NO.”

Keyway

Keyway

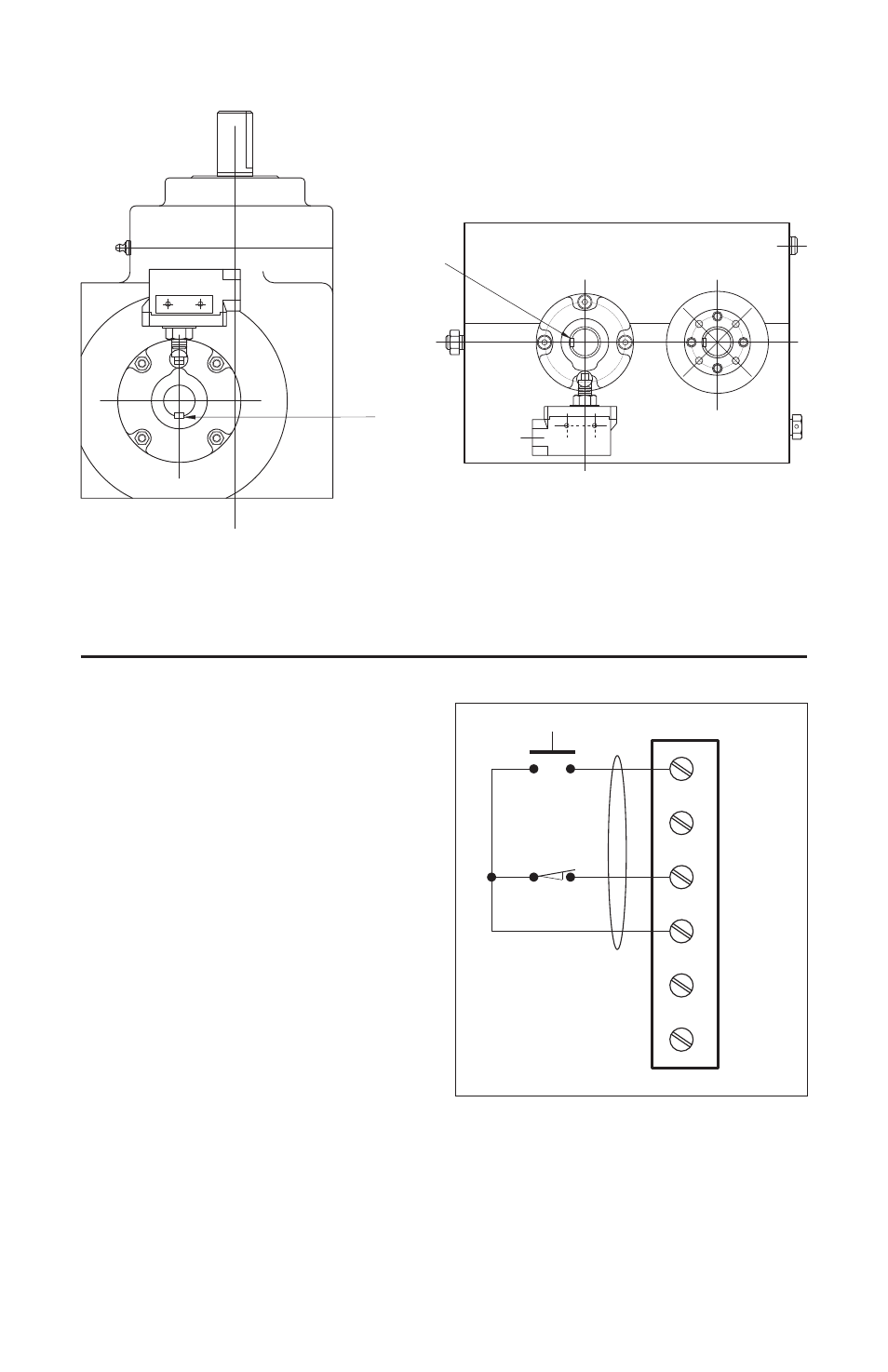

FIGURE 14B – RIGHT ANGLE UNIT

A standard right angle unit with the CAM &

Limit Switch mounted on the housing has a

correct keyway position directly opposite of

the CAM Lobe. CAM & Limit Switch may also

be mounted on the reducer.

FIGURE 14C – PARALLEL UNIT

A standard parallel unit with the CAM & Limit

Switch mounted on the housing has a correct

keyway position directly opposite of the output

shaft, 90º (clockwise) from the CAM Lobe. CAM

& Limit Switch may also be mounted on the

reducer.

MOMENTARY

START

1

2

3

4

5

6

RUN

JOG

STOP

RTN

+24V

COM

LS1 (N/C)

SWITCH

(N/O)

See section IV,

items 1-4,

on page 9

FIGURE 15 – CYCLE ON DEMAND WIRING