Bray 7000_8000 Series User Manual

Page 3

Installation and Maintenance Manual

Series 7000 and 8000 Ball Valves

Date: August 2011 / Page 3 of 9

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK,

Inc.

Tel:

832.912.2300

© 2011 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston,

Texas

77041

www.flow-tek.com

pipeline. Removing any actuation and controls may

make service easier.

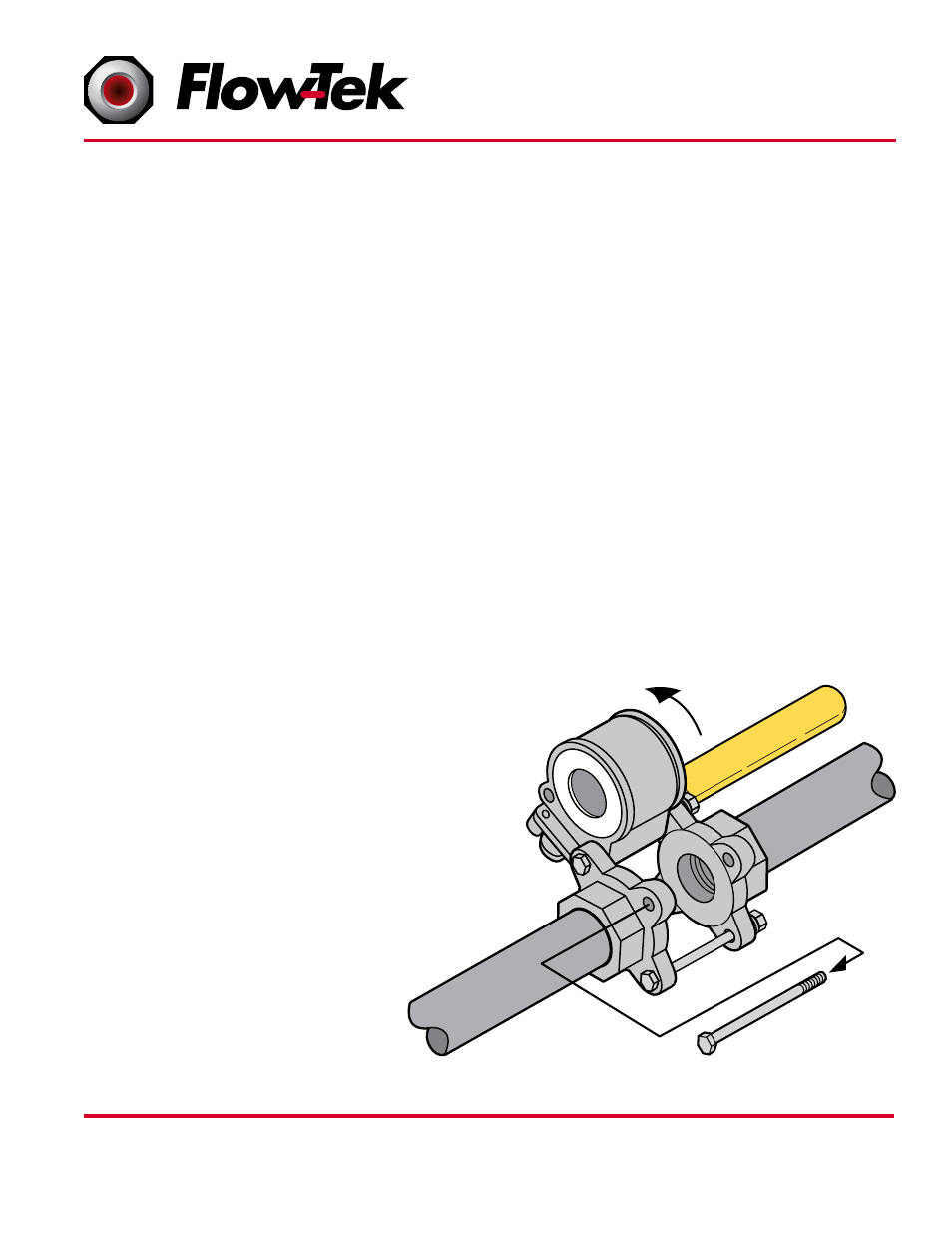

2. Remove one of the upper body bolts (all but one set

of screws for 6” thru 12”) and loosen the remaining

bolts. The center body will swing out for service,

leaving the end caps in place on the pipe ends.

3. To completely remove the valve from the pipeline,

remove the remaining upper body bolt and the

body will lift free. Gently support the body in a

vise to complete the remainder of the disassembly.

To avoid damage to the seal surfaces, hold the

body horizontally across its diameter, not across

the end faces.

4. Remove the seats and end seals.

5. 1/2” thru 2-1/2” sizes; Remove the handle nut

and handle. Straighten the tab on the tab washer

and remove the lock nut. Remove the tab washer,

Belleville washers and gland sleeve.

6. 3” and 4” sizes; Loosen the handle set screw

and remove the handle. Remove the snap ring,

travel stop, housing bolts and housing. Remove

the packing gland bolts, gland, gland sleeve and

washers.

7. 6” thru 12” sizes; Loosen the handle junction

head set screw and remove the handle assembly.

Remove the snap ring, travel stop, housing bolts

and housing. Remove the packing gland bolts,

gland, gland sleeve and washers.

8. To remove the ball, rotate the stem so the ball is

fully closed. Lift the ball from body, using a strap

and lift device if necessary. NOTE: Extreme caution

should be taken to avoid damage to the ball.

9. The stem must be removed from inside the body -

a tap on the top of the stem should loosen it. The

thrust washer should come out with the stem. Then

remove the stem packing.

Disassembly for servicing seats and stem seals may

be performed without removing the end flanges from

the pipeline.

This feature allows the removal of the valve from

service without disturbing piping connections.