Seating & unseating torques, Class a, Class b – Bray 31U User Manual

Page 7: Class c

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Resilient Seated Butterfly Valves – Seating & Unseating Torques

Torque : 7

Seating & Unseating Torques

1.

For aqueous processes and water, Class A torques may be

used only if a Nylon 11 coated disc is selected and all other

Class A characteristics apply. Otherwise, Class B torques

should be used.

2.

All the material trims may be classified into Class A, B, or

C except Series 20/21 valves with a PTFE Lined Elastomer

seat, PTFE molded disc/stem, or rubber molded disc/stem.

These trims must always use Class C Seating/Unseating

Torque Values unless they are used only in a throttling

application. Valves with bonded seats must always be

classified as Class C.

3.

If a valve is used strictly in a throttling application, that is,

it is never put in the closed position but throttled between

20° and 80°, then Class A torques may be used provided

you have checked to see that dynamic torques do not

exceed the Class A torque values.

4.

With the exception of dry, non-lubricating medias, one

is usually safe electing to use Class B torques for sizing

actuators for all other valve service applications. Seating/

Unseating Torque values shown include friction bearing

torques for stated differential pressure.

5.

Dynamic Torque values are not considered.

See the Dynamic Torque chart in this manual for

determination of Dynamic Torque.

6.

Do not apply a safety factor to torque values when

determining actuator output torque requirement.

7.

For 3-way assemblies where one valve is opening and

another is closing, multiply torque by a 1.5 factor.

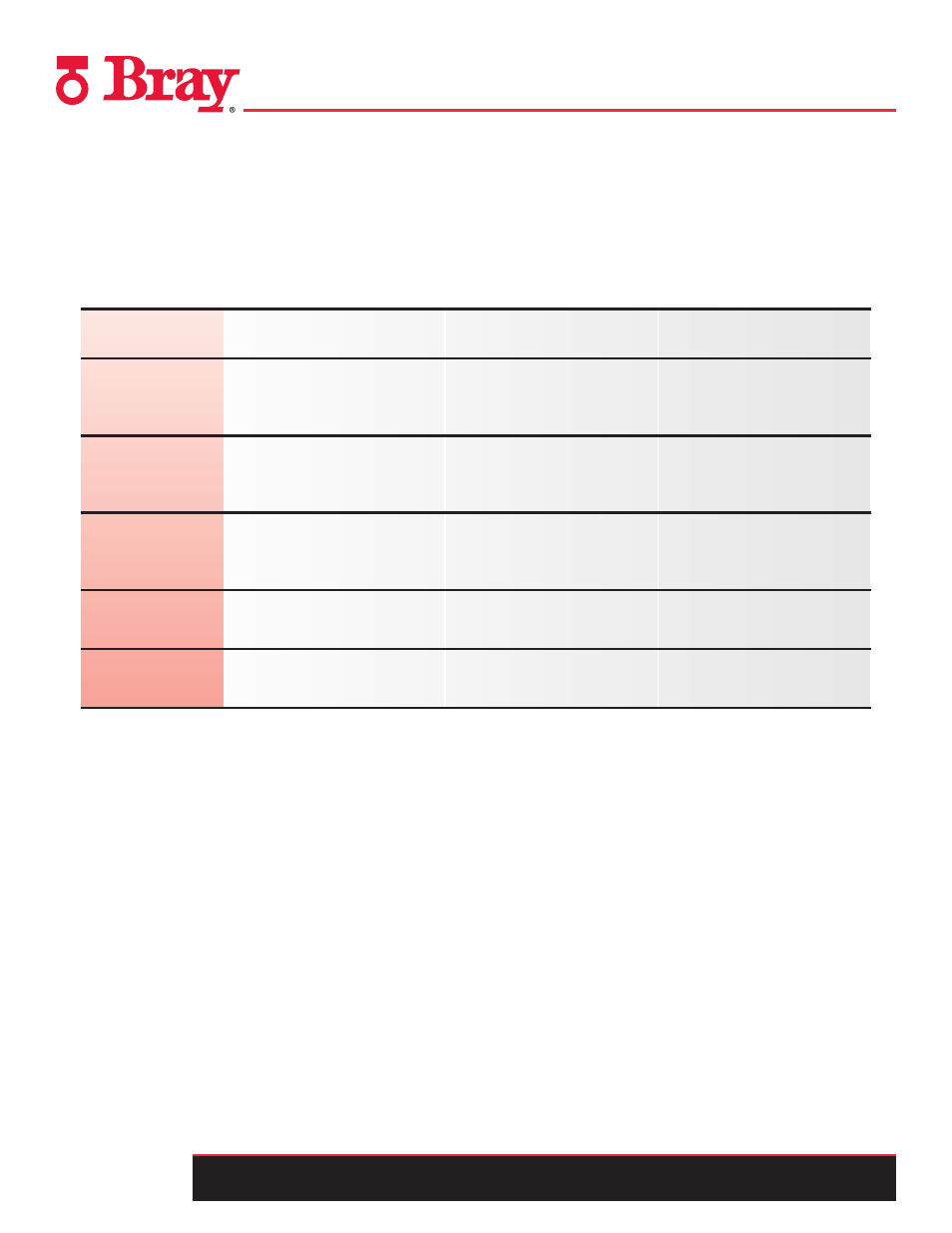

Characteristics of

Application

Class A

Non-Corrosive, Lubricating Service

Class B

General Service

Class C

Severe Service

Media Type

Lubricating hydrocarbons;

Aqueous processes and Water

(See Note 1)

Water; aqueous processes; all

other aqueous liquids including

salt water; Lubricating gases

Dry, non-lubricating such as air,

dry gas, cement, pneumatic

conveying mediums

Corrosion

by Media

Insignificant if any

No major corrosion or deposits

from media

Can incur significant

corrosion such as Ductile Iron

disc in water

Chemical

Reactions of Media

with Seat

Insignificant if any

Only minor or insignificant in

nature

Reactions causing swelling and

hardness occur

Media

Temperature

45º to 160ºF

(7º to 71ºC)

Within seat temperature limits,

not near limits

Near or at seat temperature

limits

Frequency of

Valve Cycling

Once weekly or more frequently

Minimum once every 3-6 weeks,

or more frequently

Infrequently, sometimes not

cycled for long periods

Bray has developed Seating/Unseating Torque Charts for three

Classes of Service for its valves with standard discs (rated for

full pressure) and for valves with reduced diameter discs (rated

for 50 PSI / 3.5 bar.).

The guidelines for selecting a Class to be used for determining

a valve’s seating/unseating torque are given below. Each valve

application should comply with all five Class characteristics in

order to be qualified for that Class.

NOTE: