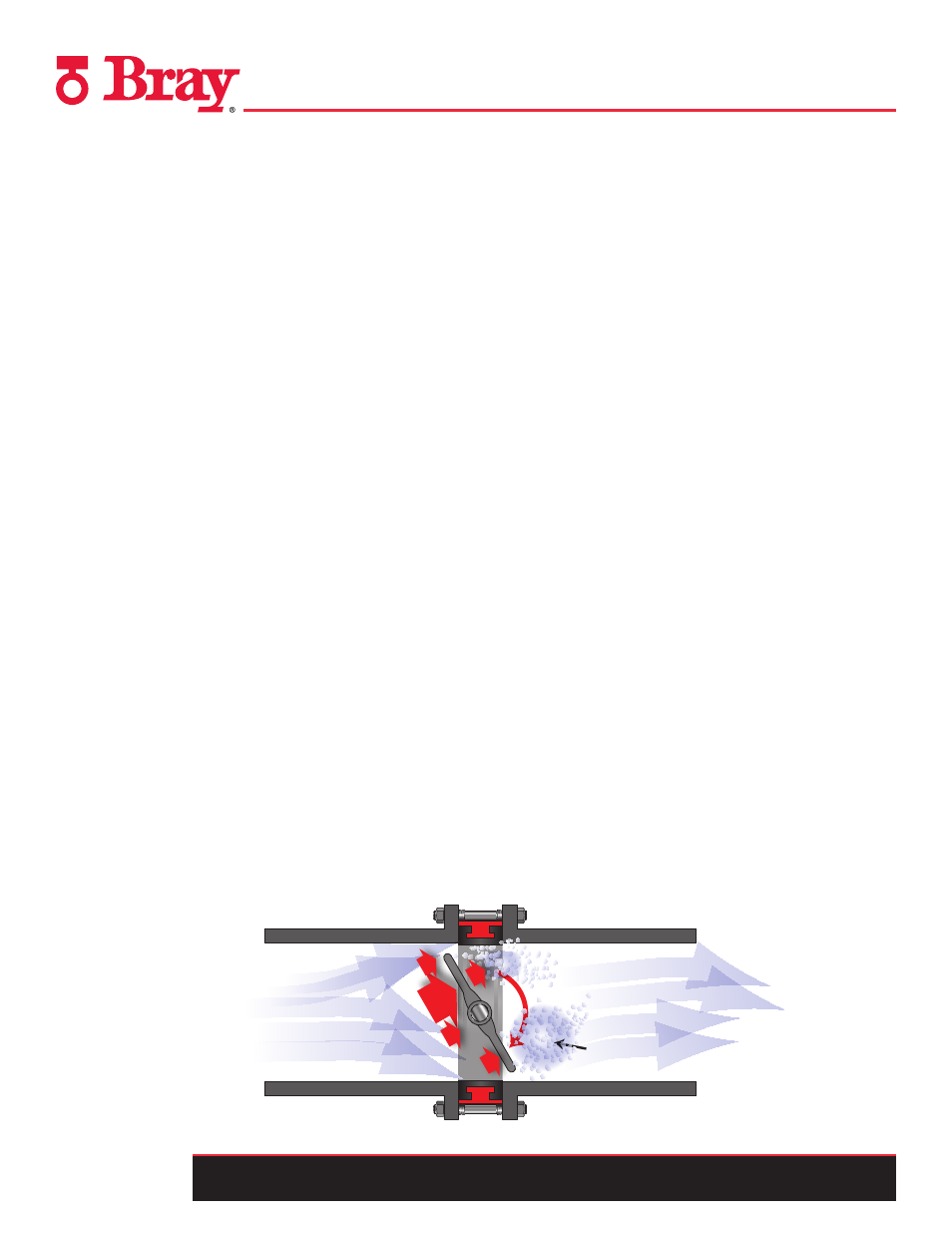

Flow, Resilient seated butterfly valves – torques, Figure 1 - pressure distribution – Bray 31U User Manual

Page 4: More turbulence here, Case ii

Resilient Seated Butterfly Valves – Torques

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Introduction : 4

D. Seating/Unseating Torques (T

su

)

The seating/unseating torque value (T

su

) is a function of the

pressure differential, the seat material’s coefficient of friction,

the finished surface of the disc edge, the amount of interference

between the seat I.D. and disc O.D. when flanged in piping, the

seat thickness, and the type of service (media) for which the valve

is being used. In determining the T

su

values for Bray resilient

seated butterfly valves, Bray has developed Seating/Unseating

Torque Charts incorporating all bearing friction and stem seal

friction torques for three classes of services for both the valves

with standard discs (rated to full pressure) and for valves with

reduced diameter discs (rated for 50 psi [3.5 bar]). The three

service classes are:

Class I – Non-Corrosive, Lubricating Service

Class II – General Service

Class III – Severe Service

Please review the guidelines for each class in the technical

manual when determining which Seating/Unseating Torque Class

should be used. Most butterfly valves are used in Class II, General

Service applications.

E. Total Torque (T

T

)

The total torque values for Bray symmetrical disc valves for Case

I applications are shown in the Seating/Unseating Torque Charts

within this manual.

CASE II

(Disc in Partial To Full Opening Position)

T

T

= T

bf

+ T

ss

+ T

d

The total Torque for Case II using a symmetrical disc butterfly valve

is the summation of bearing friction torque, stem seal friction torque

and dynamic torque.

A. Bearing Friction Torque (T

bf

)

See Case I discussion. This torque value is normally included in

the Dynamic Torque Value.

B. Stem Seal Friction Torque (T

ss

)

See Case I discussion. This torque value is normally included in

the Dynamic torque value.

C. Dynamic Torque (T

d

)

In a symmetrical disc design, dynamic torque occurs between the

closed position, 0° and the full open position, 90°. With the disc in

the partially open position, velocity of the fluid passing the leading

disc edge is less than the velocity passing the trailing edge. This

variance in velocity past the leading disc edge and trailing disc

edge results in an unbalanced distribution of pressure forces on

the upstream side of the face of the disc. The total pressure forces

acting perpendicular to the disc face on the leading edge half of

the disc are greater than the total pressure acting perpendicular on

the trailing half of the disc. This uneven distribution of pressure on

the disc face (exists on both sides of the disc) results in a torsional

force which tries to turn the disc to the closed position (Figure 1).

This torsional closing force can become greater than the seating/

unseating torque value depending on the valve angle of opening

and differential pressure.

To determine dynamic torque, the following equation is applied:

T

d

= C

dt

d

3

∆P

Where:

T

d

= Dynamic Torque (lbs- in).

C

dt

= Coefficient of Dynamic Torque (based on disc shape

and angle of opening) (dimensionless)

d

= Diameter of Disc (Inches)

∆P = Pressure Differential Across Valve (psi)

FLOW

MORE

TURBULENCE

HERE

Clo

sin

g T

or

qu

e

Pr

essur

e F

or

ces

Figure 1 - Pressure Distribution