Bray 31U User Manual

Page 22

Resilient Seated Butterfly Valves – Flange Bolt Tensioning Data

All information herein is proprietary and confidential and may not be copied or reproduced without the expressed written consent of BRAY INTERNATIONAL, Inc.

The technical data herein is for general information only. Product suitability should be based solely upon customer’s detailed knowledge and experience with their application.

Mounting : 22

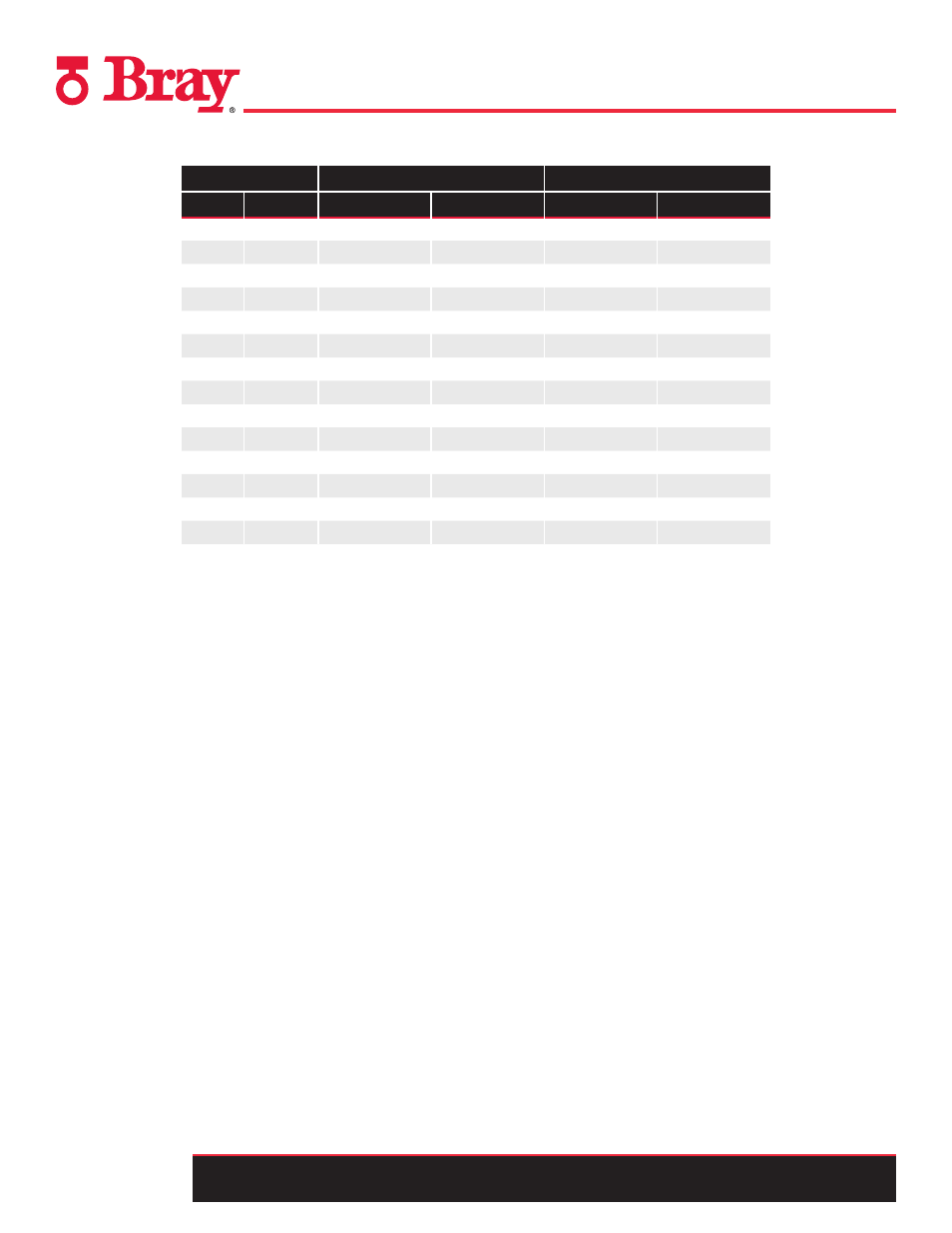

Series 22/23 Installation - Flange Bolt Torque Chart, 150 lb Flanges

Valve Size

Normal Torque Range

Max Torque Range

In

mm

Ft-lbs

N-m

Ft-lbs

N-m

2

50

30

40

35

50

2.5

65

30

40

35

50

3

80

35

50

40

55

4

100

35 - 40

50 - 55

40

55

5

125

35 - 45

50 - 60

50

65

6

150

35 - 50

50 - 65

65

90

8

200

45 - 55

60 - 75

80

110

10

250

55 - 75

75 - 100

100

135

12

300

65 - 110

90 - 150

120

165

14

350

75 - 120

100 - 165

140

190

16

400

75 - 120

100 - 165

140

190

18

450

85 - 130

115 - 175

170

230

20

500

85 - 130

115 - 175

180

245

24

600

100 - 150

135 - 205

220

300

The torque values are based on using new, coarse-

threaded, lubricated fasteners. Up to 15% may be

added to the Normal Torque Range values when using

non-lubricated fasteners. However, the maximum

torque should not be exceeded.

Flange gaskets are normally not used for installation

of S22/23 valves. Flange leakage may be caused by

combination of out-of-parallel and/or misaligned

flanges, and surface damage on the flange face and/or

the face of the valve seat. In such cases, suitable flange

gaskets may be used to control flange leakage.

Torque values specified by manufacturers of certain

flanges, for example plastic flanges, could be lower than

the values specified above. In such cases, the flange

manufacturers’ torque values must not be exceeded.

Use flange gaskets if necessary to secure flange seal.