Setting the torque switching, 1 setting, 2 checking the torque switches – AUMA Electric multi-turn actuators SA 07.1 - 48.1_SAR 07.1 - 30.1 NORM User Manual

Page 17: Torque setting 17, Tripping torque 17, Setting, Checking the torque switches

11.

Setting the torque switching

11.1 Setting

.

The set torque must suit the valve!

.

This setting should only be changed with the consent of the

valve manufacturer!

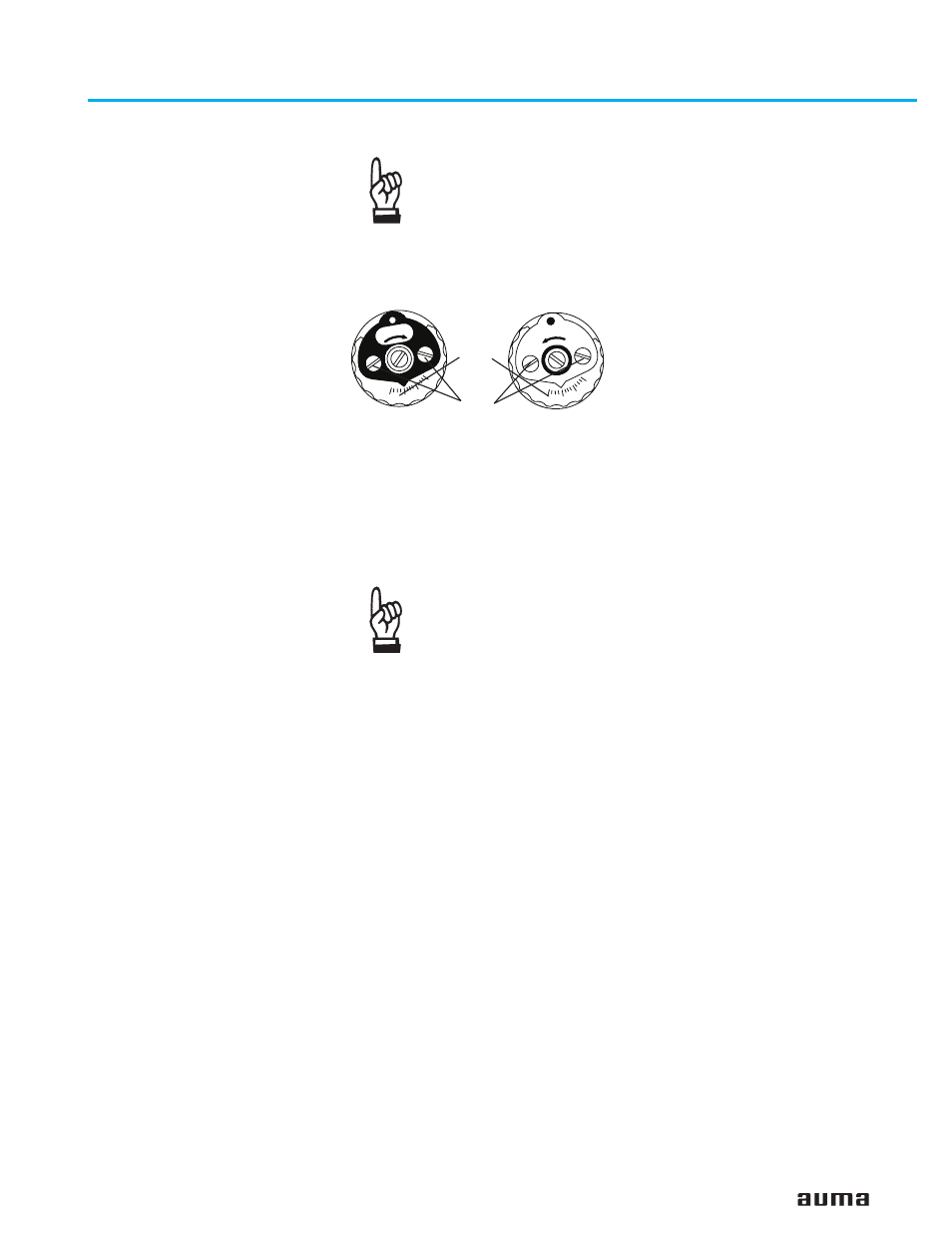

Setting CLOSED

Setting OPEN

.

Loosen both lock screws O at the torque dial (figure L).

.

Turn torque dial P to set it to the required torque.

Examples:

Figure L shows the following setting:

35 ft lbs for direction CLOSE

25 ft lbs for direction OPEN

.

Tighten lock screws O again

.

The torque switches can also be operated in manual

operation.

.

The torque switching acts as overload protection over full travel,

also when stopping in the end positions by limit switching.

11.2 Checking the torque switches

The red test buttons T and P (figure K-2) are used for manual operation of the

torque switches:

.

Turning T in direction of the arrow TSC (DSR) triggers torque switch CLOSED.

.

Turning P in direction of the arrow TSO (DÖL) triggers torque switch OPEN.

.

If a DUO limit switching (optional) is installed in the actuator, the intermediate

position switches will be operated at the same time.

17

Multi-turn actuators SA 07.1 – SA 48.1 / SAR 07.1 – SAR 30.1

Operation instructions

AUMA NORM

Ft. Lbs

Ft. Lbs

15

35

45

25

45

25

15

35

Figure L: Torque switching heads

indication in ft lbs

O

P