Using kepco bop 1kw for solar device testing, Bop 1kw solar device testing features and benefits, Bop-gl 1000 watt model table – Atec Kepco-BOP-1 Series User Manual

Page 5

KEPCO, INC. • 131-38 Sanford Avenue • Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718) 767-1102

Email: [email protected] • www.kepcopower.com

USING KEPCO BOP 1KW FOR SOLAR DEVICE TESTING

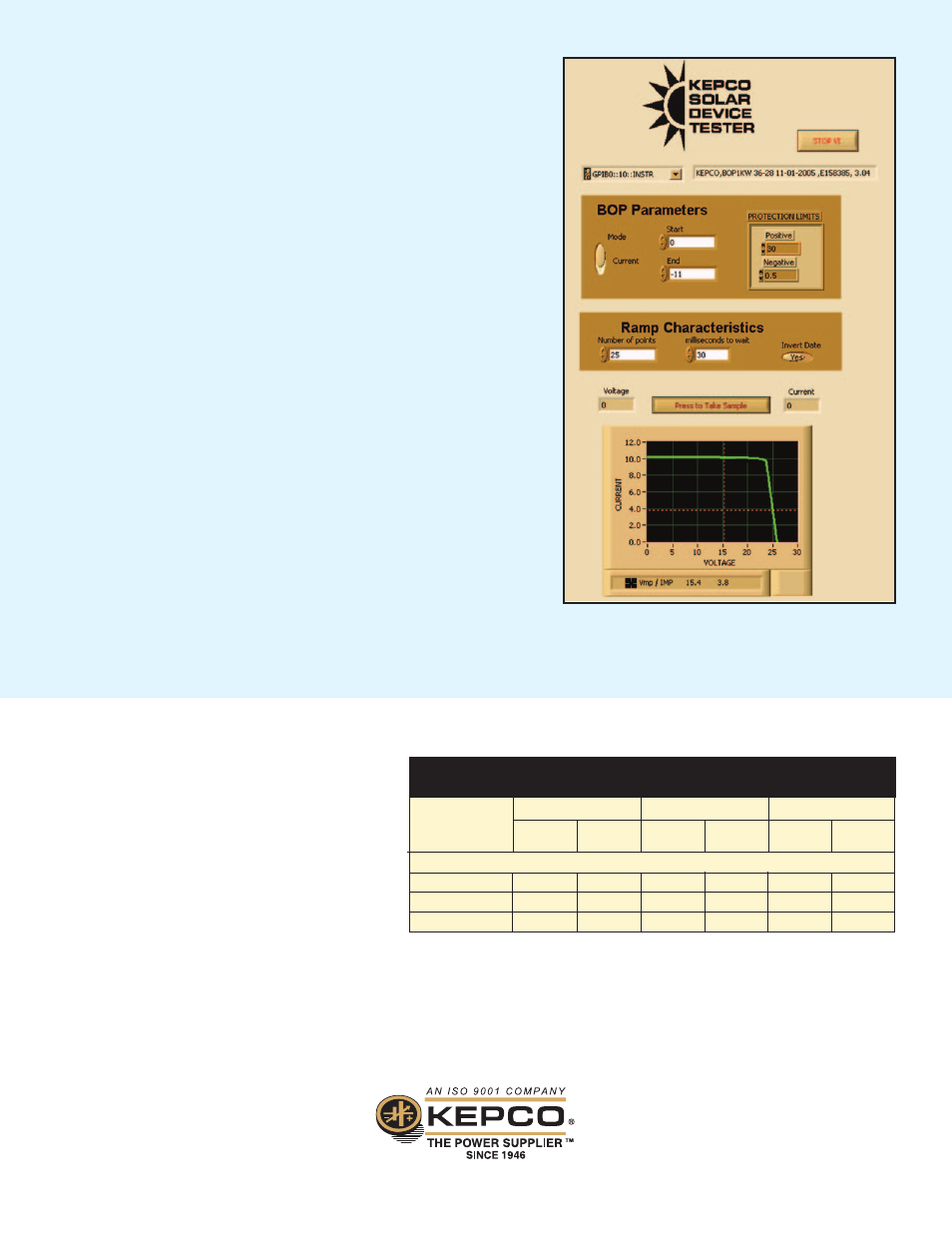

Demonstration Application Interface Showing User Inputs

and Rendered I-V Curve Output

The Kepco BOP 1KW provides a one-step solution for test and characterization

of solar cells and solar panels. A free LabView subvi allows rapid

characterization of the solar device using only the BOP 1KW, eliminating the

need for separate DVMs to measure voltage and current. The subvi is designed

for both I-V Trace and Dark I-V testing, and can be plugged in or easily adapted

to existing LabView test applications, even those previously using two DVMs.

This solution offers lower cost, greater throughput and increased ROI when

testing solar devices.

BOP 1KW SOLAR DEVICE TESTING FEATURES AND BENEFITS

• SOLAR DEVICE TESTING - Both I-V Trace and Dark I-V Tests supported.

• FLEXIBILITY - KEPCO BOP 1KW LabView Driver allows Solar Device testing while

maintaining full functionality of the BOP 1KW Instrument Power Supply features.

• FASTER THROUGHPUT - 20mS per point.

• ROI - Test setups are quick and easy, require no special programming for

synchronization, require no dedicated engineering resources to design and/or

maintain components comprising a custom solution.

• LOWER COST AND SIMPLICITY - No need to purchase, maintain and calibrate

two DVMs - Simplifies calibration, test setup and operation; no trigger

connections needed.

• RELIABILITY - With all triggering and measurements done within BOP 1KW

there are no synchronization or noise issues.

• PROVEN TECHNOLOGY - Enhancement of proven BOP 1KW technology.

• ENERGY CONSERVATION - Employs energy recuperation as well as active

Power Factor Correction (PFC).

NOTE: When connecting active loads, the steady-state voltage of the active load must not exceed

the maximum voltage rating of the BOP. Otherwise the overvoltage protection will shut down the

power supply.

For other volt-ampere combinations, consult factory.

1000 WATT

BOP 20-50GL

0 to ±20

0 to ±50

2.0

5.0

0.02%

0.01%

BOP 36-28GL

0 to ±36

0 to ±28

3.6

2.8

0.02%

0.01%

BOP 50-20GL

0 to ±50

0 to ±20

5.0

2.0

0.02%

0.01%

BOP-GL 1000 WATT MODEL TABLE

d-c OUTPUT RANGE

CLOSED LOOP GAIN

VOLTAGE

CHANNEL

Eo MAX

V d-c

Io MAX

A d-c

MODEL

CURRENT

CHANNEL

RIPPLE AND NOISE

VOLTAGE

rms

CURRENT

rms

The BOP-GL series models are a standard modification

of the 1KW that have been optimized for exceptionally

low current ripple and noise and improved stability

(drift and temperature), making them ideal for driving

inductive loads such as large magnets or motors.

These bipolar power supplies pass smoothly through

zero without switching to provide true ± voltage and

± current.

BOP 1KW GL SERIES

OPTIMIZED FOR VERY

LOW RIPPLE AND NOISE

5