Application setup recall, Material sound velocity measurements, Reduction rate measurements – Atec Olympus-45MG User Manual

Page 9

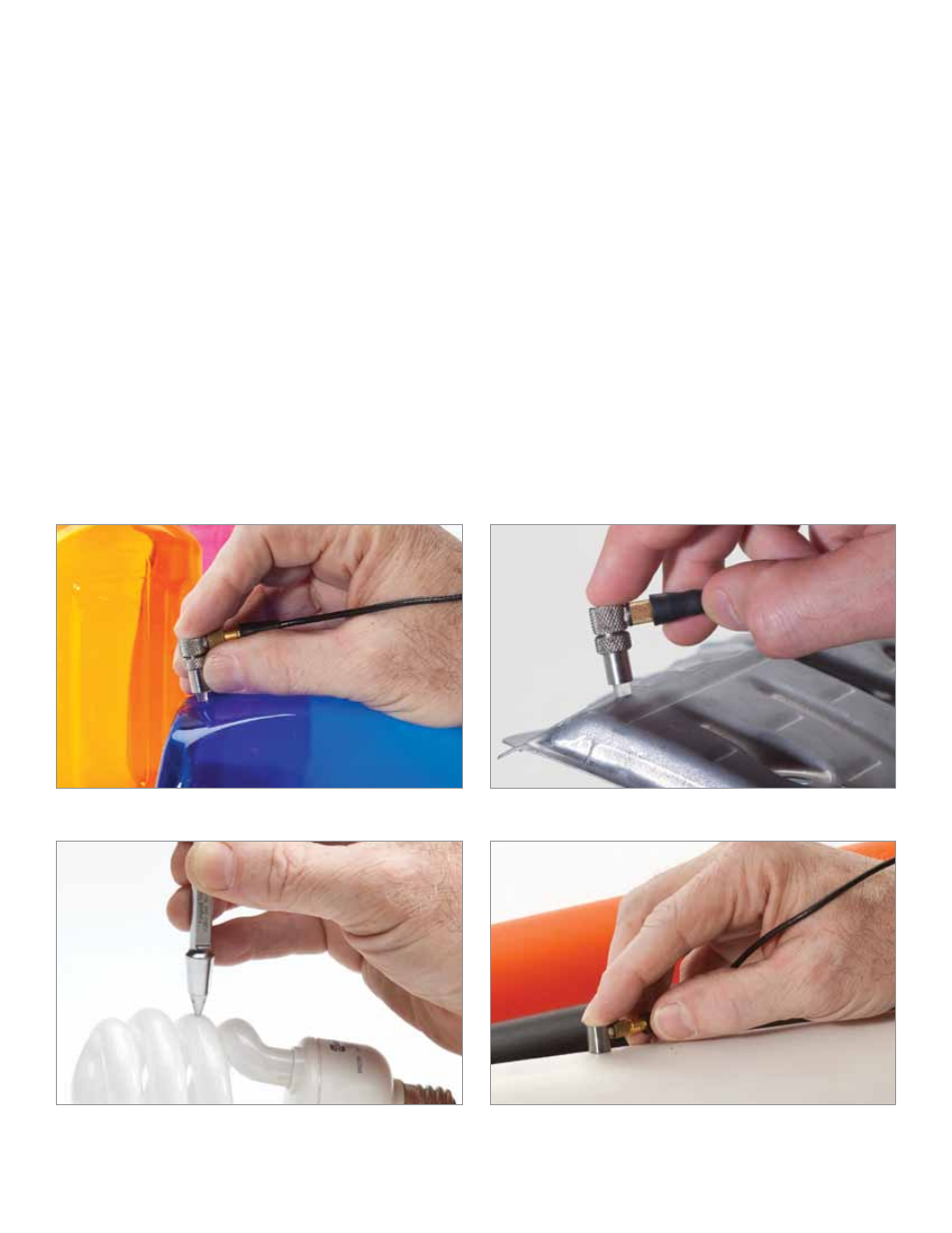

Measure metal thinning caused by bending or forming.

Measure thin plastic material using a 20 Mhz delay line transducer.

Measure thin glass with a V260-SM Sonopen

®

transducer.

Measure the thickness of many materials including plastic, metal, rubber, glass,

ceramic, and composites.

application Setup recall

Application Setup Recall simplifies making thickness

measurements. Select any of the stored transducers and

the 45MG gage recalls all relevant internal transducer

parameters.

Stored Standard Setups

The 45MG includes 21 standard single element transducer

setups for the most common applications. These default

transducer setup can be used on wide variety of thickness

applications.

Stored Custom Setups

The 45MG can store up to 35 custom single element trans-

ducer setups including calibration information. You can con-

nect the appropriate transducer and recall the setup file and

the instrument is ready to make thickness measurements on

even the most difficult applications.

Material Sound Velocity

Measurements

The 45MG has the capability to make material sound veloc-

ity measurements. This standard feature is useful in applica-

tions where the speed of sound within the material can be

correlated to other properties. Typical applications include

cast metals to monitor the degree of nodularity, and com-

posites/fiberglass to monitor variations in density.

reduction rate Measurements

Differential Mode and Reduction Rate Mode are standard

features on the 45MG. Differential Mode shows the thick-

ness variation from a pre-set thickness value. Reduction

Rate calculates and displays the percent of thickness reduc-

tion after a material thinning process. A typical application is

automotive sheet steel that is bent and formed to make car

body panels.

9