Using dual element transducers, B-scan mapping (time-based), High-temperature surfaces – Atec Olympus-45MG User Manual

Page 4

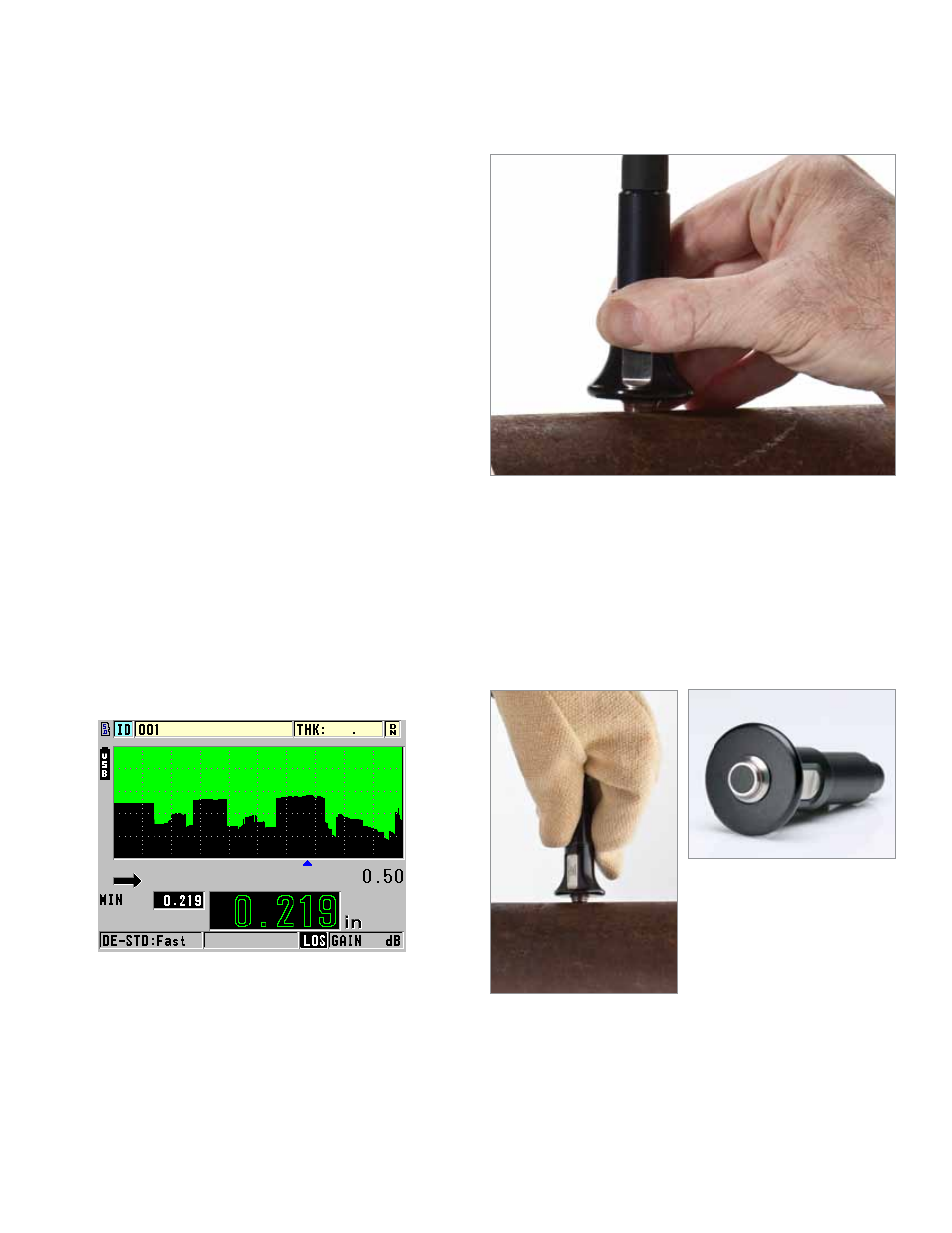

D790-SM Transducer on high-temperature

pipe

Thickness Measurements on

Internally Corroded Metals

using Dual Element Transducers

One of the major applications of the 45MG is measuring

the remaining thickness of pipes, tubes, tanks, pressure

vessels, ship hulls, and other structures affected by corro-

sion or erosion. Dual element transducers are most com-

monly used for these applications.

•

Automatic Probe Recognition for standard D79X series

dual element transducers

•

Calibration Doubling warning when echo doubling may

occur during calibration

•

The Echo-to-Echo / ThRU-COAT

®

option allows for

measurements on painted and coated surfaces

•

high temperature measurements; up to 500 °C (932 °F)

B-scan Mapping (Time-based)

The 45MG gage B-scan feature converts live thickness

readings into cross-sectional images drawn on the display.

This standard feature is very helpful in viewing the changes

in thickness measurements over a distance. The B-scan

is activated as soon as the transducer makes contact with

the surface of the material. The Freeze Minimum function

is used to display the minimum thickness of the scanned

area. The optional 45MG datalogger can store up to

10,000 thickness readings in a single B-scan.

high-Temperature Surfaces

The 45MG is ideally suited for making stable thickness

measurements on hot material surfaces (up to 500 ºC or

932 ºF) with the D790 series transducers (D790, D790 -SM,

D790-RL, and D790-SL). The Zero Compensation feature of

the 45MG enhances the accuracy of measurements on hot

surfaces by compensating for temperature changes in the

transducer delay line due to thermal drift.

Indoor display setting, B-scan mode

4