V-path builder, Automatic probe recognition – Atec Panametrics-38DL-Plus User Manual

Page 5

5

Dual Element Transducers with Automatic Probe Recognition for Corrosion Gaging Applications

Transducer

Item

Number

Freq.

(MHz)

Connector

Tip Dia.

mm (in.)

Range (Steel)*

mm (in.)

Temp. Range**

°C (°F)

Cable

Item

Number

D790

U8450002

5.0

Straight

11.00

(0.434)

1.00 to 500.00

(0.040 to 20.000)

–20 to 500

(–5 to 932)

Potted

—

D790-SM

U8450009

Straight

LCMD-316-5B†

U8800353

D790-RL

U8450007

90°

LCLD-316-5G†

U8800330

D790-SL

U8450008

Straight

LCLD-316-5H

U8800331

D791

U8450010

5.0

90°

11.00

(0.434)

1.00 to 500.00

(0.040 to 20.000)

–20 to 500

(–5 to 932)

Potted

—

D791-RM

U8450011

5.0

90°

11.00

(0.434)

1.00 to 500.00

(0.040 to 20.000)

–20 to 400

(–5 to 752)

LCMD-316-5C

U8800354

D792

U8450012

10

Straight

7.20

(0.283)

0.50 to 25.00

(0.020 to 1.000)

0 to 50

(32 to 122)

Potted

—

D793

U8450013

90°

Potted

—

D794

U8450014

5.0

Straight

7.20

(0.283)

0.75 to 50.00

(0.030 to 2.000)

0 to 50

(32 to 122)

Potted

—

D795

U8450015

90°

Potted

—

D797

U8450016

2.0

90°

22.90

(0.900)

3.80 to 635.00

(0.150 to 25.000)

–20 to 400

(–5 to 752)

Potted

—

D797-SM

U8450017

Straight

LCMD-316-5D

U8800355

D7226

U8454013

7.5

90°

8.90

(0.350)

0.71 to 100.00

(0.028 to 4.000)

–20 to 150

(–5 to 300)

Potted

—

D798-LF

U8450019

D798

U8450018

7.5

90°

7.20

(0.283)

0.71 to 100.00

(0.028 to 4.000)

–20 to 150

(–5 to 300)

Potted

—

D798-SM

U8450020

Straight

LCMD-316-5J

U8800357

D799

U8450021

5.0

90°

11.00

(0.434)

1.00 to 500.00

(0.040 to 20.000)

–20 to 150

(–5 to 300)

Potted

—

MTD705

U8620225

5.0

90°

5.10

(0.200)

1.00 to 19.00

(0.040 to 0.750)

0 to 50

(32 to 122)

LCLPD-78-5

U8800332

D7906-SM

††

U8450005

5.0

Straight

11.00

(0.434)

1.00 to 50.00

(0.040 to 2.000)

0 to 50

(32 to 122)

LCMD-316-5L

U8800358

D7906-RM

††

U8450025

90°

LCMD-316-5N

U8800647

D7908

††

U8450006

7.5

90°

7.20

(0.283)

1.00 to 37.00

(0.040 to 1.500)

0 to 50

(32 to 122)

Potted

—

Single Element Transducers for Corrosion Gaging Applications

For a complete list of single element transducers, please consult your local representative or consult our web site www.olympus-ims.com.

Transducer

Item

Number

Freq.

(MHz)

Connector

Tip Dia.

mm (in.)

Range (Steel)*

mm (in.)

Temp. Range**

°C (°F)

Cable

Item

Number

V260-SM

U8411019

15

Straight

2.00

(0.080)

0.50 to 10.00

(0.020 to 0.400)

0 to 50

(32 to 122)

LCM-74-4

U8800348

V260-RM

U8411018

90°

LCM-74-4

U8800348

V260-45

U8411017

45°

LCM-74-4

U8800348

M2017

U8415002

20

90°

6.35

(0.250)

Steel 0.50 to 12.00

(0.020 to 0.500)

Oxide 0.25 to 1.25

(0.010 to 0.050)

0 to 50

(32 to 122)

LCM-74-4

U8800348

M2091

U8415018

20

90°

6.35

(0.250)

Steel 0.50 to 12.00

(0.020 to 0.500)

Oxide 0.15 to 1.25

(0.006 to 0.050)

0 to 50

(32 to 122)

LCM-74-4

U8800348

E110-SB

U8471001

—

Straight

28.50

(1.250)

2.00 to 125.00

(0.080 to 5.000)

0 to 80

(32 to 176)

LCB-74-4 and

1/2XA/E110

U8800320

U8767104

* Dependent on material, transducer type, surface conditions, and temperature. Full range may require Gain Adjust.

** Maximum temperature with intermittent contact only

†

Stainless steel cable available; consult Olympus NDT for details.

††

Transducers used with THRU-COAT

®

technology

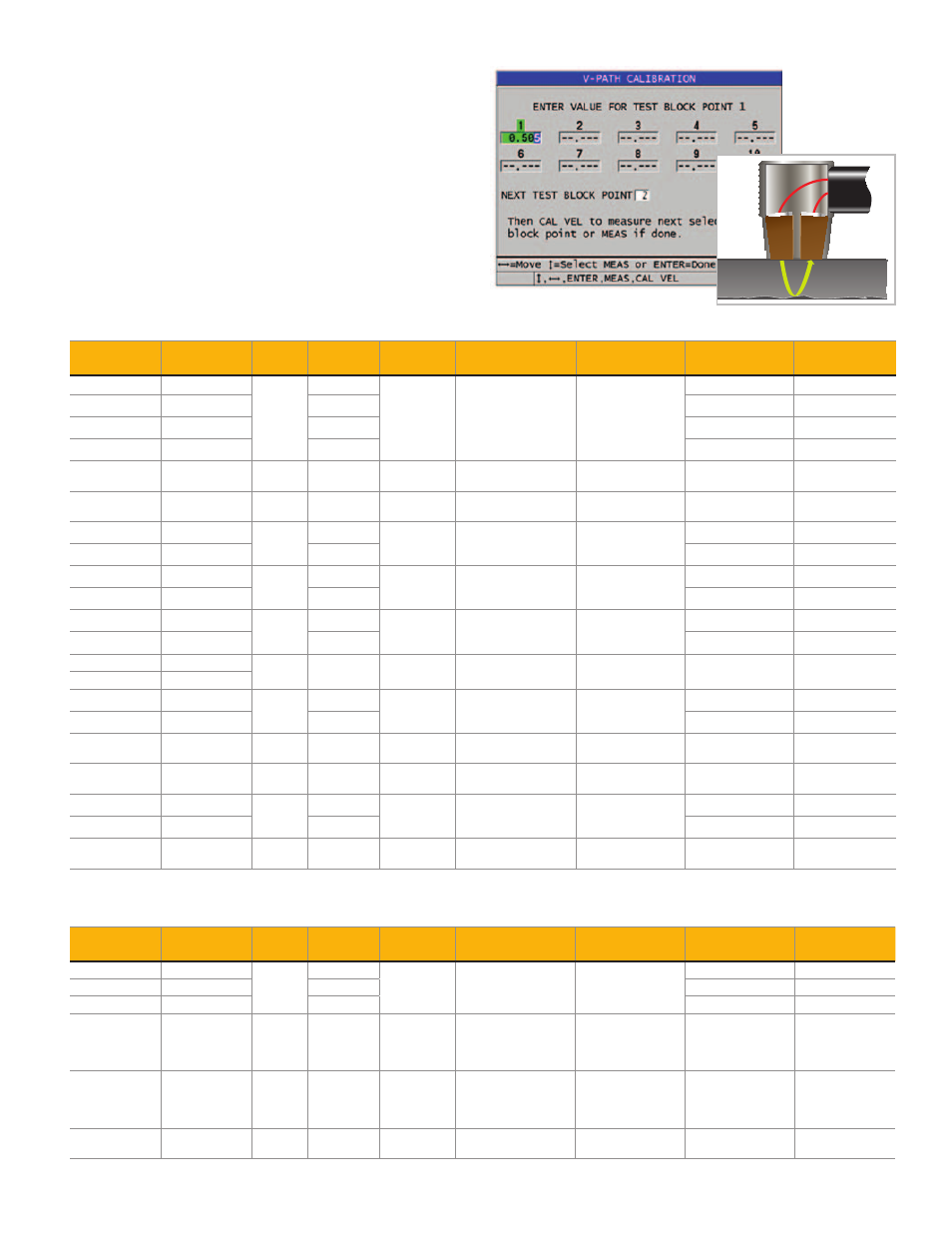

V-Path Builder

This new and patented feature allows you to build a custom

V-Path compensation curve for almost any dual element trans-

ducer. These curves can be saved and recalled along with custom

setups for most dual element transducers. You simply calibrate

and enter the known thickness with a minimum of 3 and up to

10 calibration points, and the instrument will create the V-path.

Automatic Probe Recognition

All standard dual element transducers (see chart below) feature

Automatic Probe Recognition, which automatically recalls a

default V-path correction for each specific transducer.