Thru-coat, Technology, Temperature compensation – Atec Panametrics-38DL-Plus User Manual

Page 4: Optional oxide/ scale measurement

4

www.olympus-ims.com

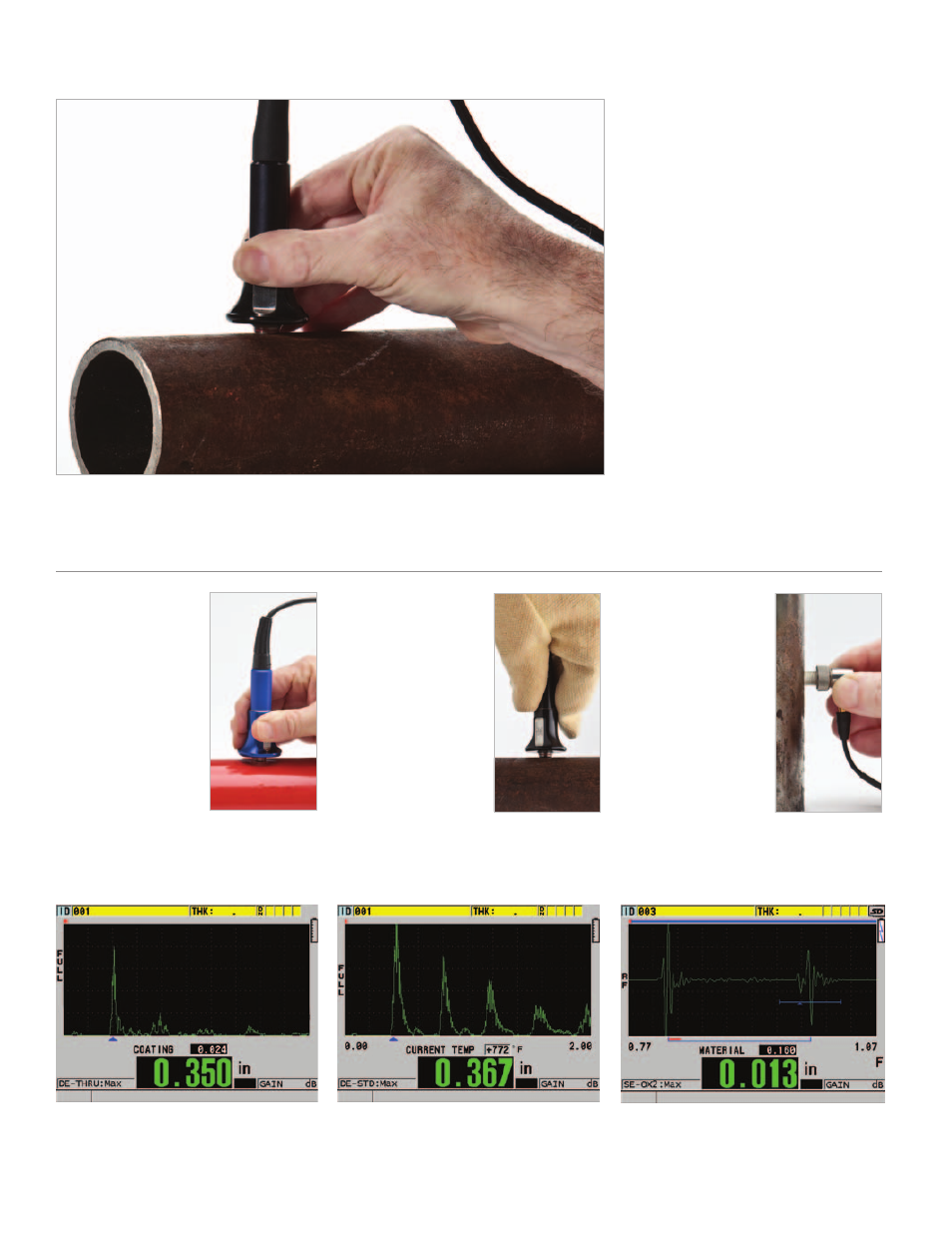

Thru-Coat

®

Technology

uses a single back-wall

echo to measure true

metal thickness. You

can display the metal

and coating thicknesses,

each adjusted for their

correct material sound

velocities. There is no

need to remove paint

and coatings from

surfaces. THRU-COAT

®

measurements use the D7906-SM,

D7906-RM, and D7908 dual element

transducers.

Temperature

Compensation

variations in mate-

rial temperature affect

sound velocity and

accuracy of thickness

measurements. The

temperature compensa-

tion feature allows you

to manually enter the

calibration block’s tem-

perature and the current

(high) temperature at

the measurement points. The 38DL PLUS

automatically displays the temperature-

corrected thickness.

Optional Oxide/

Scale Measurement

uses advanced algo-

rithms to measure the

thickness of oxide/

scale buildups inside

boiler tubes. The gage

simultaneously displays

the metal thickness of

the boiler tube and the

thickness of the oxide

layer. Knowing the

thickness of the oxide/

scale helps predict tube life. We recom-

mend using M2017 or M2091 transducers

in this application.

One of the major applications of the 38DL PLUS is measuring the remaining thickness of

pipes, tubes, tanks, pressure vessels, hulls, and other structures affected by corrosion or

erosion. Dual element transducers are most commonly used for these applications.

Thickness Measurements on Internally Corroded Metals

•

Automatic Probe Recognition for

standard D79X series dual element

transducers

•

Ten custom dual element transducer

setups

•

Optimized default gain during

calibration for dual element transducer

•

V-Path Builder for custom V-path

compensation

•

Calibration Doubling when echo

doubling may occur during calibration

•

THRU-COAT

®

and Echo-to-Echo

measurements on painted and coated

surfaces

•

High temperature measurements; up to

500 °C (932 °F)

•

Boiler tube and Internal Oxide

measurements (optional) with M2017

or M2091 single element transducers

•

EMAT transducer (E110-SB) for

no-couplant measurements of boiler

tubes with external oxide/scale buildup