Portaflow 330 technical datasheet, Data logger – Atec Micronics-PF330 User Manual

Page 5

Portaflow 330 Technical Datasheet

Portaflow 330 Technical Datasheet

5

(Issue 2.1)

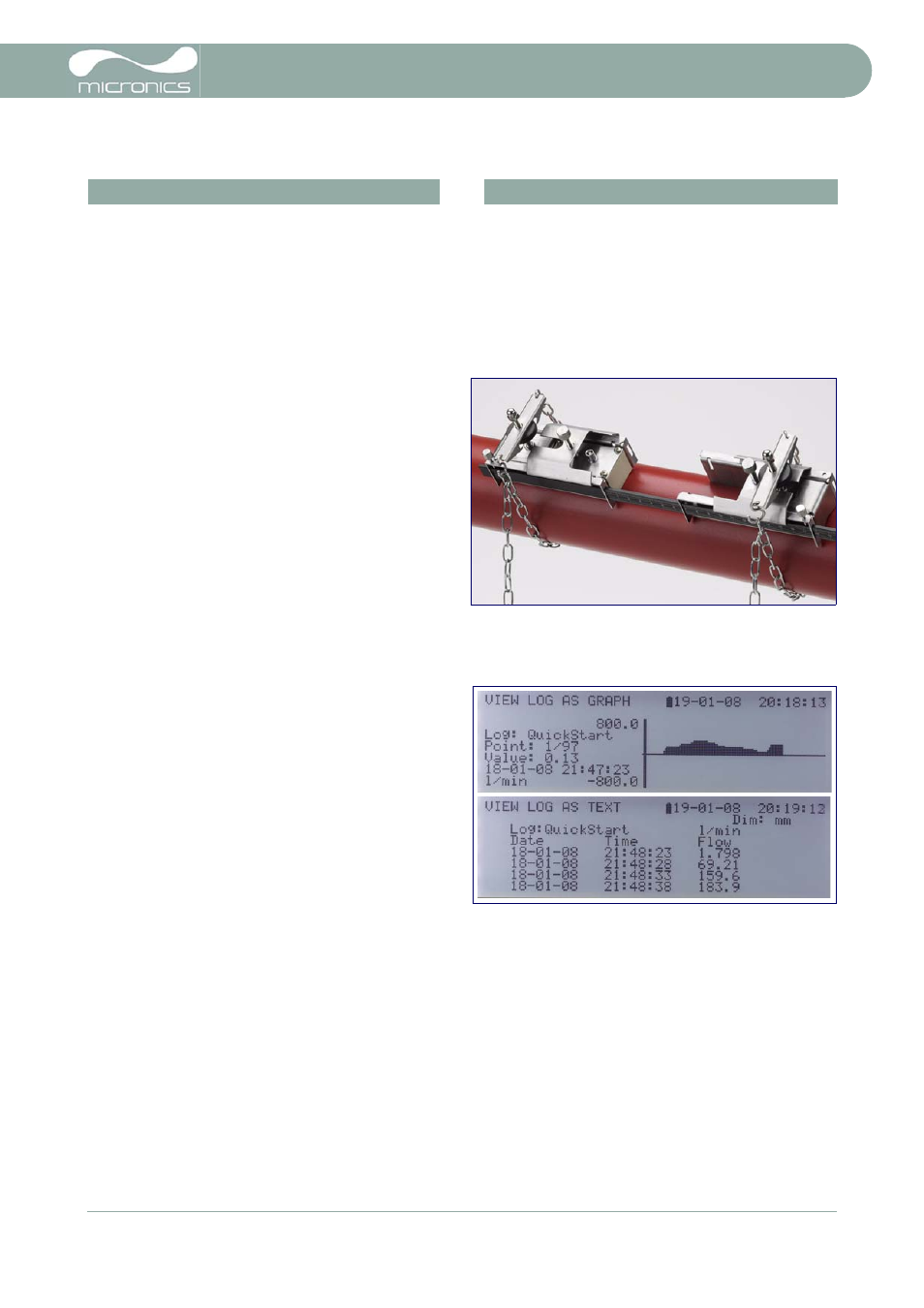

Transducer mounting

Type ‘A’ & ‘B’ transducers are fitted to adjustable guide rails

which are secured to the pipe using wrap-around chains and

mechanically connected together by a steel separation bar. The

separation bar also acts as a ruler to allow the distance between

the transducers to be set to the value calculated by the

Portaflow instrument.

A thumb-wheel is used to adjust the chain tension until the

assembly is held firmly in place. The transducers are then

inserted into the guide rails and secured in place by a knurled

screw. This illustration shows a completed assembly with a

transducer fitted to the left-hand guide rail only.

The transducers are connected to the PF330 instrument by

means of a 2m mini-coaxial cable.

Data logger

The Portaflow 330 can record and store up to 98,000 (98k)

logged events which can be displayed on the instrument either

graphically or as text. Logged data comprises date & timed

stamped flow values together with the unit of measurement and

can be downloaded to a PC using the inbuilt RS232 or USB

interface. The interval between logged events can be set between

5 secs and 1 hour.

All data is saved to non-volatile memory and is retained even if the

battery totally discharges.

When viewing the data in either mode any stored event can be

accessed and displayed using the instrument’s scroll keys – see

the attached illustration.

If logging is taking place at a ‘named site’ the log is saved with same ‘name’ as the site name and can be recalled under that name

as and when required. This allows the instrument to be used at several site locations and the results can be downloaded

independently at a later, convenient time.

When used in this way the total 98k event memory is shared between the ‘named’ sites as needed and if the memory becomes full

the instrument can be configured to either stop logging altogether or continue logging by overwriting the earlier stored data on a

first-in first-out basis for the site in use.

Logging can be controlled manually using Start/Stop menu options or set to operate automatically on a timer. The timer option is

useful if logging is required during unattended operation.

A summary of the data logger specification is shown on the following page.

Standard transducers:

Optional transducers:

Temperature range -20°C to +135°C

Temperature range -20°C to +80°C

• 'A-ST' (2MHz) – used with 13mm 115mm pipe o.d.

• 'B-ST' (1MHz) – used with 50mm 2000mm pipe o.d.

• 'D' (0.5MHz)* – used with 1500 mm…5000 mm pipe o.d.

* Note these transducers are not part of the standard Portaflow 330 kit but can be supplied as optional equipment.