Portaflow 330 technical datasheet, Principles of operation – Atec Micronics-PF330 User Manual

Page 2

Portaflow 330 Technical Datasheet

2

Portaflow 330 Technical Datasheet

(Issue 2.1)

Principles of Operation

When ultrasound is transmitted through a liquid the speed at

which the sound travels is accelerated slightly when

transmitted in the same direction as the liquid flow and

decelerated slightly when transmitted against it. The difference

in time taken by the sound to travel over the same distance but

in opposite directions is therefore proportional to the flow

velocity of the liquid and can be used to calculate the flow rate.

Transit time technique

This technique is known as ‘transit time’ measurement and is

the method used by the Portaflow 330 system to calculate the

liquid flow rate. Once the flow velocity is known it is a simple

matter for the PF330 to calculate the volumetric flow.

Operating modes

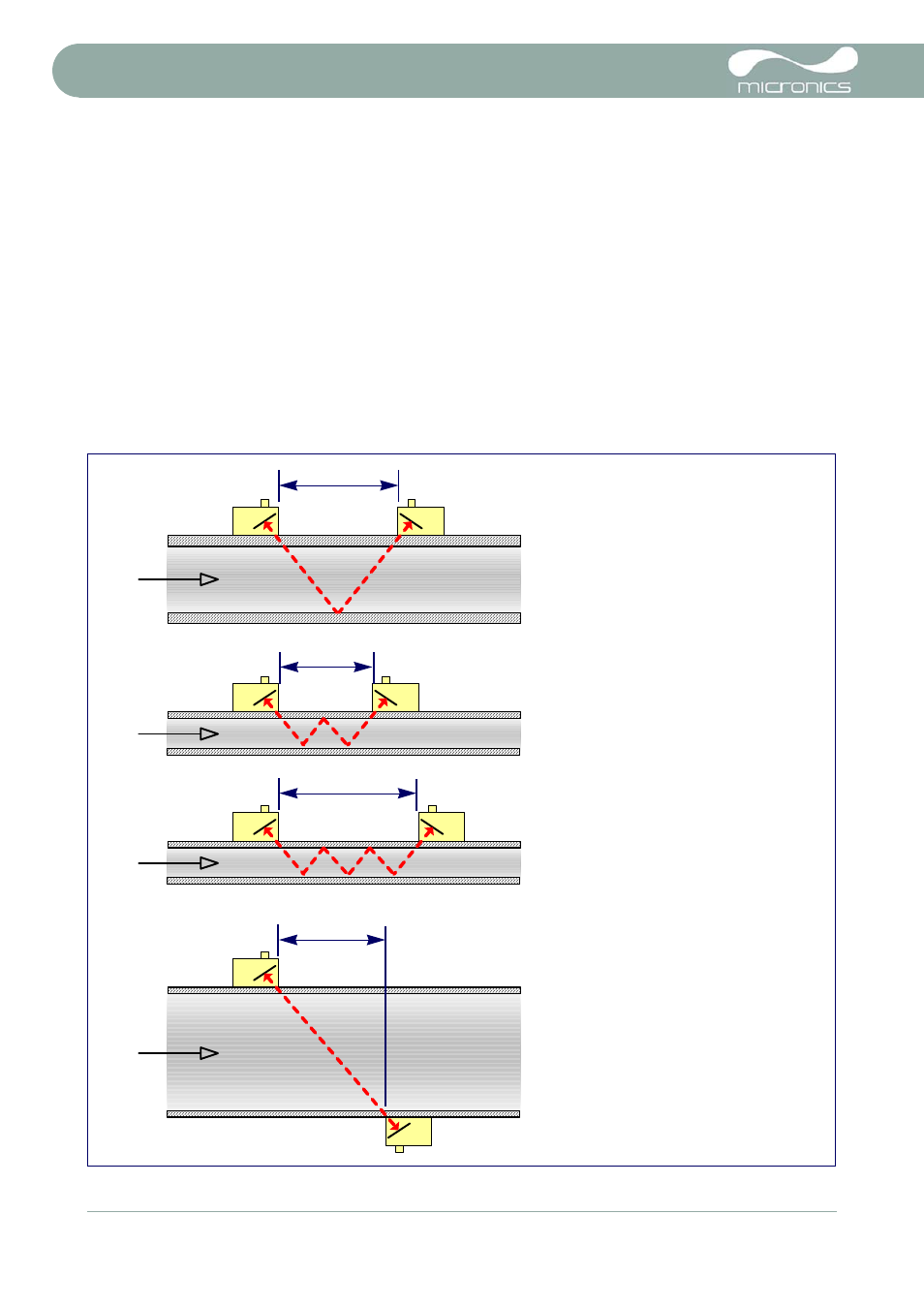

The Portaflow sensors can be set to operate in one of four

modes determined mainly by the pipe diameter and the

transducer set in use. The diagram below illustrates these

modes and shows the importance of applying the correct

separation distance between the transducers to obtain the

best possible signal.

In practice, the PF330 determines the operating mode and

calculates the appropriate transducer separation distance in

response to site application data entered by the user.

Fluid flow

Fluid flow

Fluid flow

Fluid flow

U

U

U

U

D

D

D

D

Separation

Distance

Separation

Distance

Separation

Distance

Separation

Distance

Reflex mode

Reflex mode (double bounce)

Reflex mode (triple bounce)

Diagonal mode

This is the mode most commonly used.

The two transducers (U & D) are attached

to the pipe in line with each other and the

signals passing between them are reflected

by the opposite pipe wall.

The Separation Distance is calculated by

the instrument in response to entered data

concerning the pipe and fluid characteristics.

In this mode the separation distance is

calculated to give a ‘double bounce. This is

most likely to occur if the pipe diameter is

so small that the calculated reflex mode

Separation Distance would be impractical

for the transducers in use.

This illustration goes one step further to show

a ‘triple bounce situation. This would normally

apply when working with very small pipes

relative to the transducer range in use.

This mode might be selected by the

instrument where relatively large pipes are

concerned. In this mode the transducers are

located on opposite sides of the pipe but the

Separation Distance is still critical in order

for the signals to be received correctly.

This mode might be used with the standard

‘A’ & ‘B’ transducer sets but for really large

pipe installation the optional transducer set ‘D’

might be recommended.

Upstream

transducer