Atec Micronics-PF330 User Manual

Portaflow 330 technical datasheet, Description

Portaflow 330 Technical Datasheet

1

(Issue 2.1)

Portaflow 330

Technical Datasheet

Description

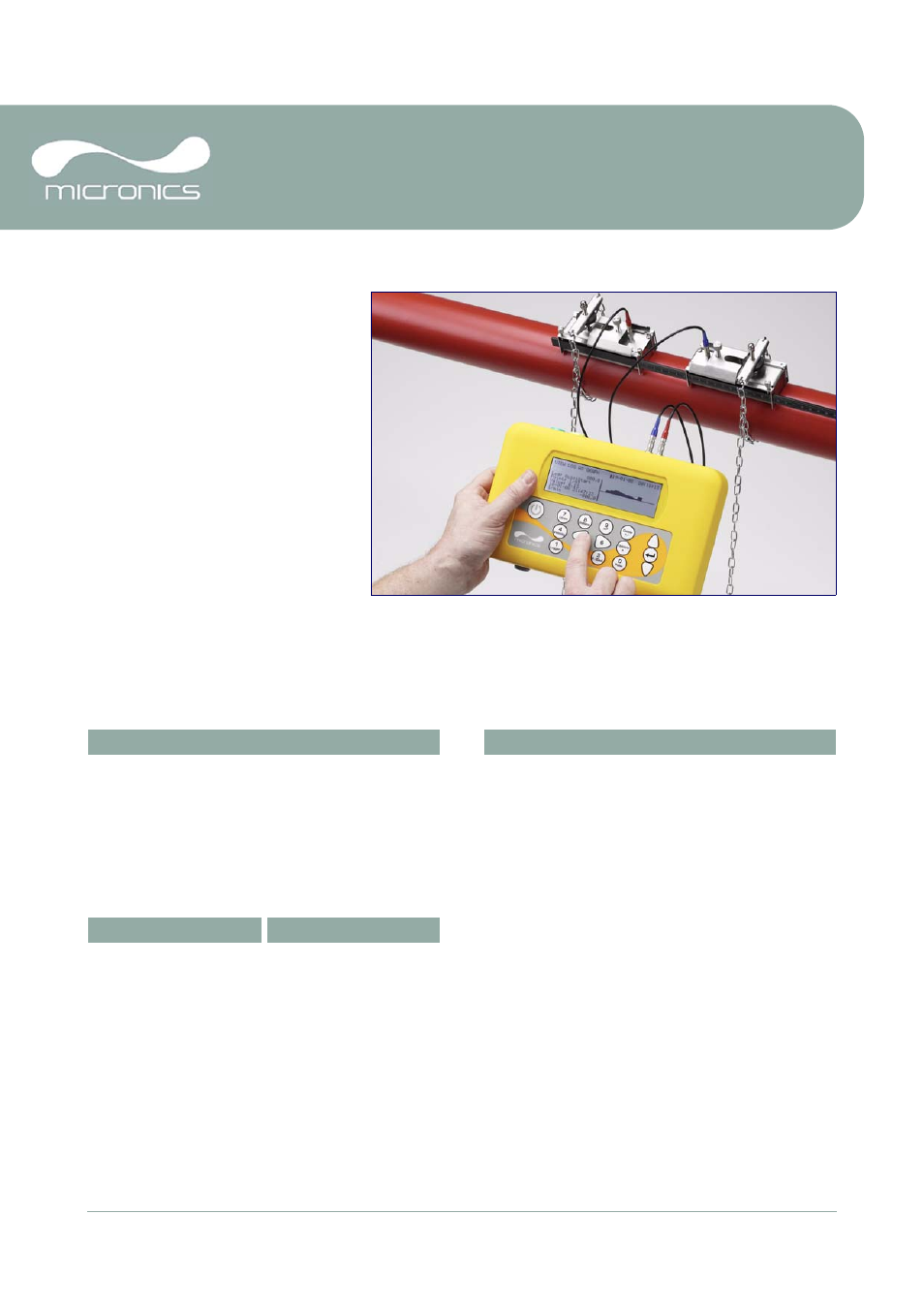

Utilising advanced DSP technology, the

Portaflow 330 (PF330) is the latest portable

flow measurement and recording system to be

added to the Micronics range of equipment.

The PF330 can display instantaneous fluid flow

rates or velocity, together with totalised values. It

also incorporates a data logger that can record

up to 98k events which can be output directly to

a PC or printer or stored in the instrument’s

memory for downloading at a later time.

A variable current or pulse output, proportional

to the detected flow rate, is also produced by the

PF330 to enable it to interface with a range of

external control devices such as those found in

building management or site monitoring

systems.

The PF330 is very much designed with ‘ease of use’ in mind. An interactive QuickStart menu, which simplifies system installation at

any suitable location, together with minimal set-up requirements, means that the system can be installed and brought into service

very quickly. Furthermore, the application parameters for a particular site can be saved to non-volatile memory and instantly

recalled if a site is revisited for monitoring at a later time – further reducing the set-up time.

The flow sensors, or transducers, connected to the PF330 instrument are attached to the outside of the pipe being monitored and

provide totally non-invasive flow measurement without disturbing the existing plant equipment or process operation.

Application benefits:

Standard features:

• Non-invasive installation – the process operation being

monitored is in no way interrupted or otherwise

affected by the use of this equipment

• Simple installation – there is no overhead for additional

fittings, plant modification, or retro-fit expenditure

• Zero fluid contact – no contamination risks of the

process fluid and possible exposure of the monitoring

equipment to corrosive or toxic liquids

• Light-weight, hand-held instrument with large, easy to

read graphic display and switchable backlighting

• Flow range 0.1m/sec to 20m/sec bi-directional

• Two types of transducer sets supplied for use with

pipes ranging 13mm - 2000mm outside diameter

• 10 selectable operating languages

• Simple to follow dual function keypad

• Simple ‘Quick Start’ set up procedure

• Continuous flow monitoring, with ‘Totalised’ option

• Data logging with up to 98k stored data points

• Data logging can be controlled manually or set-up for

timed operation, allowing unattended operation

• Logged data can be viewed as text or graphically, with

the ability to scroll to any stored event

• RS232/USB outputs for downloading data logger

contents to PC. Live data logging also available at these

outputs

• Pulse output, 4-20mA, 0-20mA or 0-16mA output with

simple range calibration

• Rechargeable battery with up to 20hrs continuous

battery operation depending on load

• Mains/battery operation with battery management

Industries:

Applications:

• Water

• Building services

• Energy management

• Power generation

• Petrochemical

• Oil/Gas

• Food/drink

• Pharmaceuticals

• Power plants

• Manufacturing

• HVAC & energy system

audits

• Pump verification

• Metering

• Process control

• Chemical addition

• Hydraulic systems

• Fire systems

• Leak detection

• Boiler testing