Battery simulator battery/charger simulators – Atec Keithley-2302-2306D User Manual

Page 2

www.keithley.com

1.888.KEITHLEY

(U.S. only)

S

p

E

c

Ia

L

Iz

E

d

p

O

W

E

R

S

U

p

p

L

IE

S

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Fa

st

tra

nsi

en

t r

espo

ns

e

pow

er

su

pp

lie

s

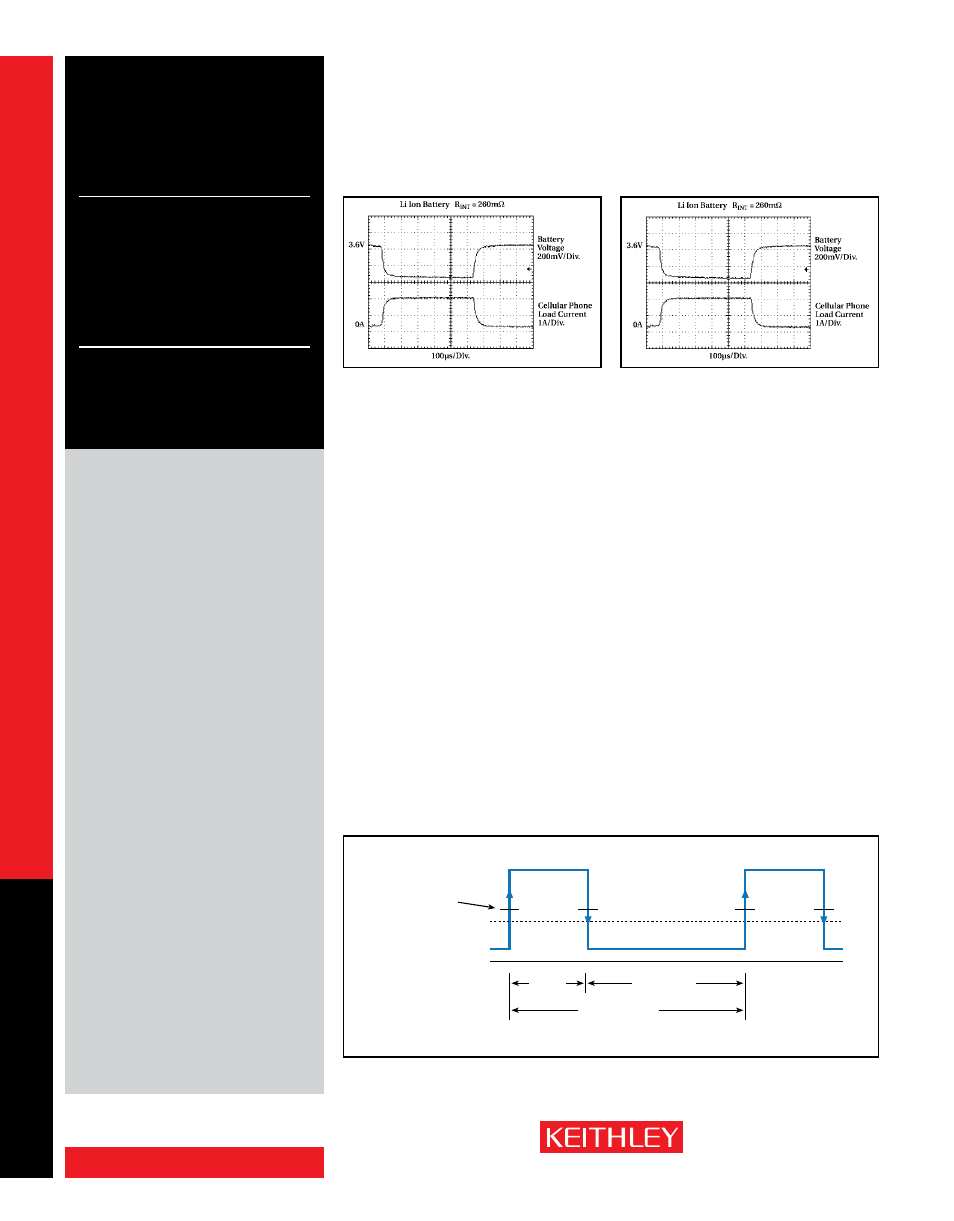

In response to large load changes, the Model

2302 and the battery channel of the Model 2306

have transient voltage droops of less than 100mV

and transient recovery times of less than 60µs,

even when the test leads between the power

supply and the DUT are long. This fast transient

response, combined with the supplies’ vari-

able output resistance, allows engineers to test

their portable products under the most realistic

operating conditions and eliminate false failures

due to conventional power supplies with slow

response times. (See the sidebar titled “Con-

ventional Power Supplies and Wireless Device

Testing.”) These supplies also eliminate the large

stabilizing capacitors needed at the DUT to com-

pensate for the large droop that occurs when

testing with conventional power supplies. By

varying the output resistance, which can be done

while the output is turned on, test engineers can

simulate the operation of different battery types,

as well as batteries nearing the end of their

useful lives.

The Models 2302 and 2306 ensure maximum

production throughput when testing portable

devices by minimizing false failures, minimizing

the number of test setups by performing mul-

tiple tests with the same power supply, and mini-

mizing test fixture complexity by eliminating the

need for voltage-stabilizing capacitors.

Measure Load currents for

power consumption Verification

or analysis

As manufacturers of portable devices strive to

extend their products’ battery life, measuring

load currents accurately has become increasingly

essential in both design and production test in

order to ensure the product meets its demanding

specifications. Comprehensive testing of these

devices requires measuring peak currents, aver-

age currents, and baseline currents in various

operation modes. When testing these devices,

these measurements are complicated by the pul-

sating nature of load currents, such as the trans-

mit and receive load currents of digital cellular

phones. The Models 2302 and 2306 can measure

the peak and average currents of pulses as short

as 60µs and as long as 833ms. (See Figure 3.)

Ordering Information

2302

Battery Simulator

2306

dual-channel Battery/

charger Simulator

2306-pJ dual-channel Battery/

charger Simulator

with 500ma Range

accessories Supplied

User and service manuals,

cS-846 output connectors

mating terminal

conventional power Supplies

and Wireless device Testing

During production testing, supplying

power to a device that undergoes large,

instantaneous load current changes can be

extremely difficult. Changes like this force

a conventional power supply’s output volt-

age to fall instantaneously. When the power

supply’s control circuitry senses the error

condition (the difference in voltage between

the programmed level and the actual

level), it attempts to correct or restore the

voltage to the programmed level. During

this time, the voltage will fall or droop

substantially, with the amount of the droop

depending on the size of the load current

change. The recovery time depends on the

transient response of the power supply’s

control loop. Conventional power supplies

have transient voltage drops of >1V when

confronted with load current changes of

up to 1000%, and take up to a millisecond

to recover to the programmed voltage. For

portable devices such as cellular phones

that operate at full power for only short

intervals, the full power event is over before

the conventional power supply can recover.

For example, a cellular phone designed to

the GSM cellular phone standard transmits

and receives information in 576µs pulses. If

the power supply used to test these types of

phones cannot recover quickly enough, the

performance of the phone during testing

will be compromised by the power supply.

If the power supply voltage drops below the

threshold of the phone’s low battery detec-

tion circuitry for long enough, then the

phone will turn off during testing, giving a

false indication of a failed device.

Figure 2. comparison of the voltage outputs of a lithium-ion battery (with an internal resistance of

260m

Ω) and the Model 2306’s battery channel (programmed with an output resistance of 260mΩ)

when powering a cellular telephone as it makes the transition from standby mode to transmit mode.

High current level

Trigger level

Average current level

High

Time

Low current level

Low Time

Average Time

(out to 60s with long integration)

Figure 3. Built-in pulse current measurement functions allow test engineers to measure peak,

average, and baseline load currents.

2302

2306, 2306-pJ

Battery Simulator

Battery/Charger Simulators