Measurement accuracy – Atec Anritsu-MA2445A User Manual

Page 9

9

Measurement Accuracy

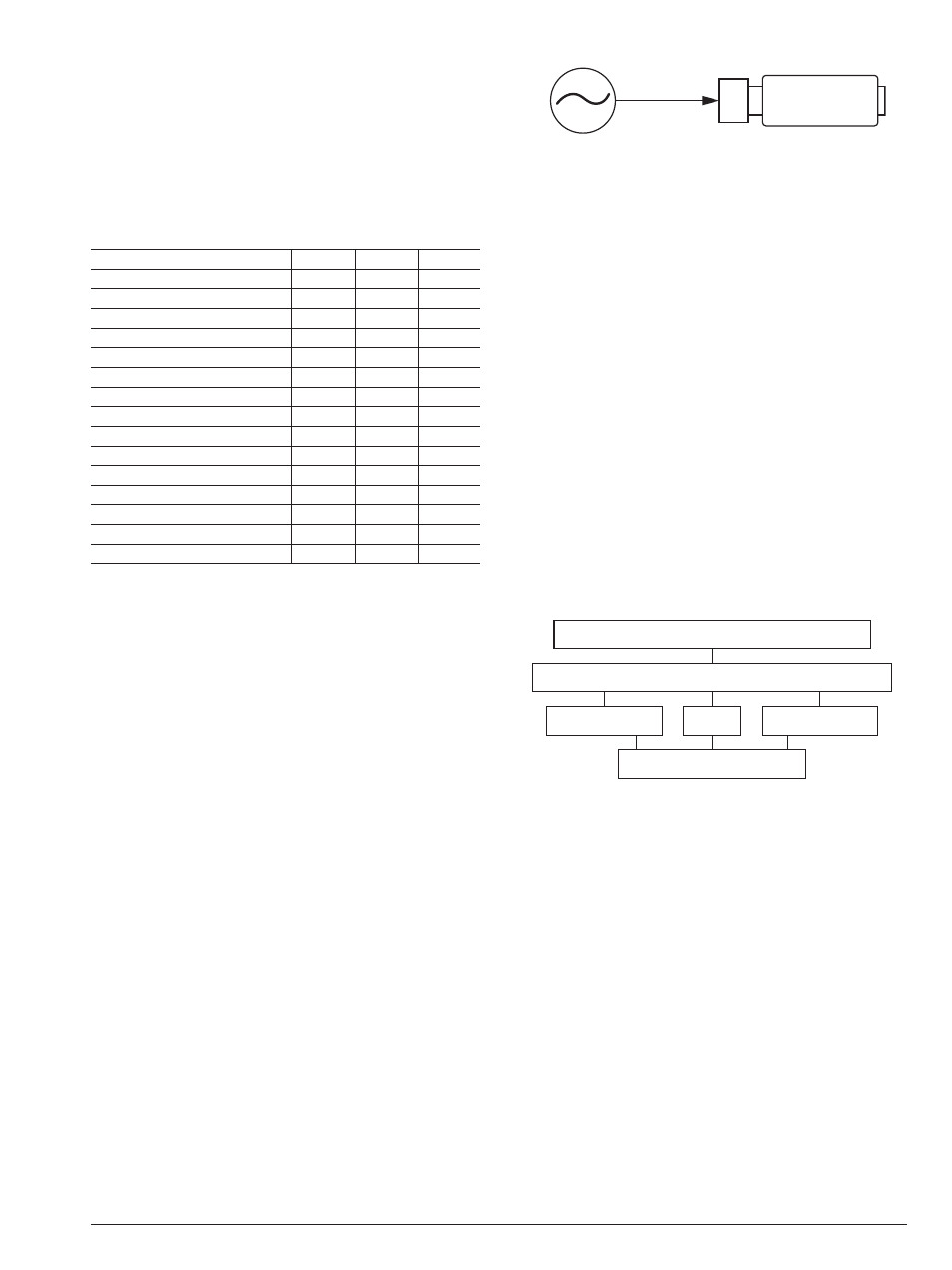

Power measurement accuracy can be split into several parts.

The table below shows how the measurement uncertainty is

composed for several power sensors. The source is presumed

to be a 16 GHz, 12.0 dBm signal with a source SWR of

1.5:1.

The uncertainties can be calculated as an RSS term as each

parameter is independent. Alternatively they can be added

together for a worst-case analysis.

MA2440D

MA2491A

MA2470D

Instrumentation Accuracy

0.50%

0.50%

0.50%

Sensor Linearity

1.80%

3.50%

1.80%

Noise, 256 Avg.

0.00%

0.00%

0.00%

Zero Set and Drift

0.00%

0.00%

0.00%

Mismatch Uncertainty

3.84%

4.49%

4.49%

Sensor Cal Factor Uncertainty

0.79%

1.59%

0.84%

Reference Power Uncertainty

1.20%

1.20%

1.20%

Reference to Sensor Mismatch Uncertainty

0.23%

0.31%

0.23%

Temperature Linearity

1.00%

1.00%

1.00%

RSS, Room Temp

4.51%

6.06%

5.09%

Sum of Uncertainties, Room Temp

8.36%

11.59%

9.06%

RSS

4.62%

6.14%

5.18%

Sum of Uncertainties

9.36%

12.59%

10.06%

The Instrumentation accuracy of 0.5% is a very small

component of the overall uncertainty budget and describes

the linear voltage measurement accuracy of the power

meter.

Sensor linearity

describes the relative response over the

dynamic range of the sensor, and is included when the sen-

sor is measuring power levels relative to the 0 dBm calibra-

tor reference level. Temperature linearity is included when

operating the sensor at other than room temperature.

Noise, Zero Set and Drift

are all measured on the lowest

power range of the power sensor. Different types of power

sensors have different noise characteristics. Noise can be

reduced by averaging.

Mismatch uncertainty

is typically the largest component of

the uncertainty budget – caused by the different impedances

of the device under test and the sensor. To help resolve this

issue, the sensor has been designed to have a good return

loss over a wide frequency range, typically achieving

significantly better results than the specification. In many

cases the major contributing factor is the match of the

source under test.

Mismatch is easily calculated in either dB or percentage terms from the source’s and

sensor’s respective reflection coefficients.

The source match of the device under test can be improved

by the use of precision attenuators with good return loss or

by the use of external levelling with a high directivity

coupler or splitter.

Connector damage has significant accuracy and repeatabili-

ty effects, and is also the most common cause of sensor

damage – although it is frequently undetected. Every

MA2400A/D Series includes a hex nut connection for

application of a calibrated torque wrench. Torque wrenches

assure compliance with the quality requirement and result in

more consistent measurements.

Sensor calibration factor uncertainty

identifies the accuracy

of the sensor's calibration relative to a recognized standard for

absolute power level. Sensor calibration factor uncertainty is

included in accuracy calculations for any absolute power

measurement (in dBm or Watts) and for relative power

measurements if the signals are different frequencies.

ML2400A Series is NIST traceable for more accurate, dependable measurements.

Reference power uncertainty specifies the maximum

possible output drift of the power meter's 50 MHz,

0.0 dBm power reference between calibration intervals.

Reference power uncertainty and reference to sensor

mismatch uncertainty do not generally impact relative

power measurements.

See the Anritsu website (www.anritsu.com) for more

information and tool to calculate measurement uncertainties.

Power Sensor

Reflection Coefficient = Γ

2

Reflection Coefficient = Γ

1

P

0

% Mismatch Uncertainty = 100 [(1 ± Γ

1

Γ

2

)

2

–1]

dB Mismatch Uncertainty = 20 log (1 ± Γ

1

Γ

2

)

NIST, National Institute of Standards and Technology

Anritsu, Microwave Measurement Division Standards Labs

Anritsu Service

Factory

Customer Cal Lab

Power Meter End User