N-351gf-15_5 – Cla-Val 351GF-15 User Manual

Page 5

5

will be difficult because the sleeve must be in position to per-

mit the ball to recede by gravity out of the path of the reinsert-

ed lockpin with its spring this after getting the ball to enter its

hole from the lockpin gallery.

Reassembly of Model 351GF-15

It is suggested that the following list of new unused O-Rings

should be on hand for reassembly

2 each 00794J

1 only 00779K

1 only 00718H

1 only 200293C Back-up Ring

Materials and tools required

Loctite – Thread locker 222-Service Removable

Grease – To retain Steel balls in sockets and lube O-Rings to

ease installation.

0.250 Hex (Allen) wrench

1/4" Box or open end wrench

3/8" Box or open end or socket wrench

1/4" Box or open end or socket wrench

.045 thick blade screw driver

.094" Hex (Allen) wrench

1/8" or smaller pin or drift punch

Combination slip joint pliers (to hold 28290-01D Pin-link to poppet

stem for installation)

Pedestal (right circle cylinder) or 3"x 3" block both 3" or more

high 14"x14" cut-down box.

One of the 0079J O-Rings can be saved for back-up replacement

on the 28276 Seat Assembly providing the suggestion on pg 4.

about exercising care when removing the 00794J O-Ring has

been followed.

If the 28291-01B Lockpin has been removed it with the 200279-01K

Spring should be reinstalled and retained with the 200275-01D

Screw.

Loctite Thread locker 222 Service Removable or equal on the

200275-01D 8- 32 Screw is recommended.

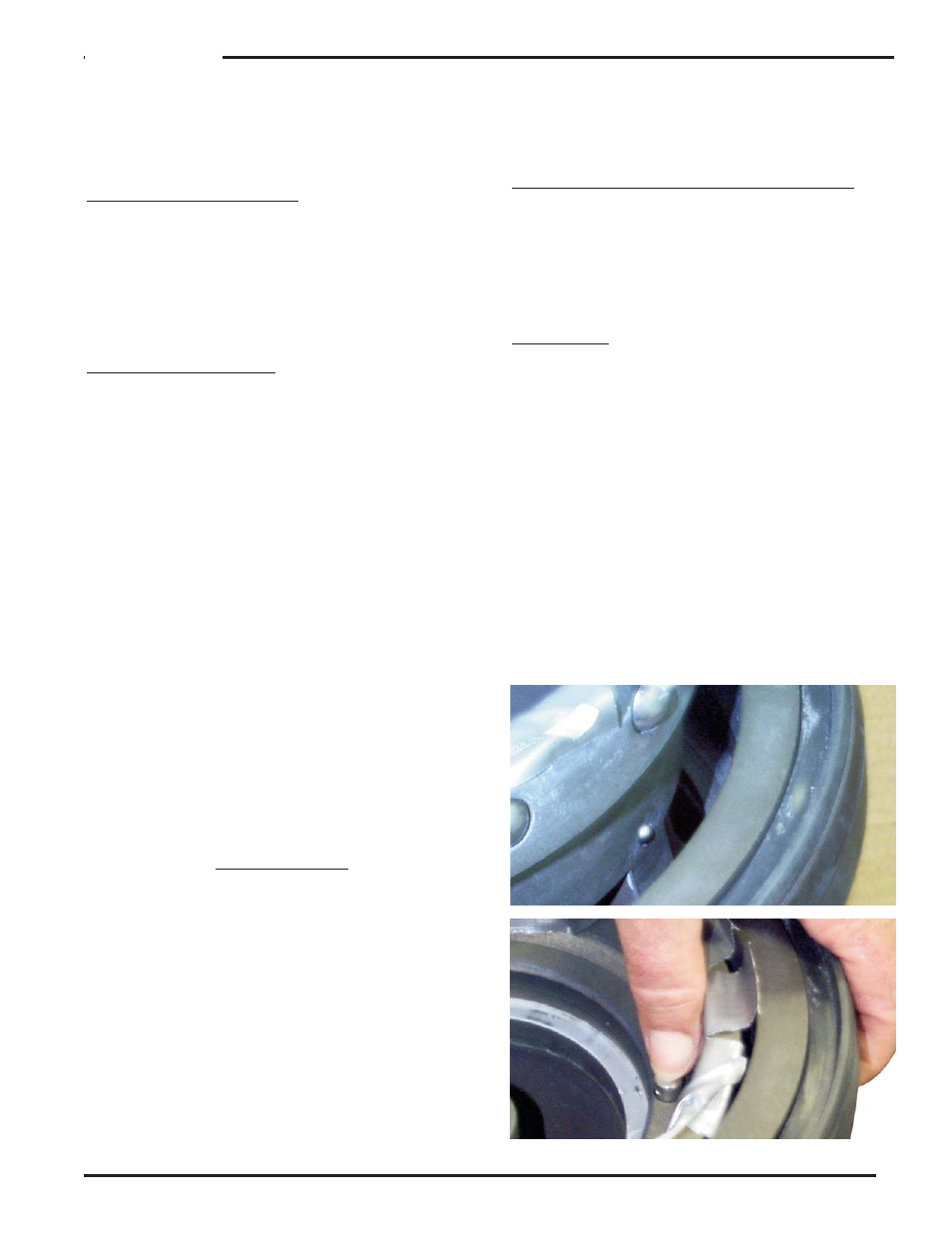

Reinstallation of the Steel Ball 90290-05K for the lockpin and

the 12 each 90290-06F Steel Balls is facilitated by the use of

a dab of grease in the cavity for each ball to retain them when

installing the 28278-01F Sleeve or length of duct tape.

To install the 28282-01A body with lockpin assembly and Steel

balls into the 28278-01F Sleeve, the sleeve can be inverted on

a smooth bench surface and inside the 14x14 box then the

body carefully inverted and lowered into the sleeve. The

28278-01F Sleeve is carefully lifted and the 28291-01B

Lockpin depressed to provide a indentation recess for the

90290-05K Ball allowing the sleeve to be pulled up capturing

the 12 Steel balls in their sockets, then release the lockpin dri-

ving the 90290-05K Ball to engage the annular detent groove

in the inside diameter of the sleeve. Return the body/sleeve

assembly to the upright position. Install 28289-01F Crank with

the 71988-40G washer into the body.

Note a light coat of grease on the shaft of the crank will aid the

placement of the 00718H O-Ring and back-up ring.

The sequence of reassembly can vary at this point.

A - The crank installation can be completed by placing the

O-Ring and back--up ring followed by the 28287-01K Delrin

bearing, then the handle and its retainer with a drop of Loctite

on the bolt.

B - The 28279-01G Stem Poppet (less the 28280-01E poppet)

can be inserted in the body to a full-up position.

Assembly Aid:

Resting the poppet stem on a cylindrical pedestal of 3 or more

inches high and approximately 3" diameter (an inverted tin

can) will facilitate the next steps of the assembly sequence.

With the assembly resting on the pedestal, rotate the body

while restraining the poppet stem (use the 28283-01J link in

the slot of the poppet stem) to a position such that the slots in

the body are 90º relative to the slots in the poppet.

In position as described above, the 5/16" hole in the poppet

stem will be aligned with the slots in the body allowing the

28290-01D Pin to be inserted through the poppet stem and

28283-01J Link. (See Fig 8.) With the link retained in the stem,

the two components can be rotated in the direction of 12

o’clock where the pin will be captured in stem guide area of

the body. With the 200873 Stepped Pin in hand, the link and

crank are aligned by turning and twisting to permit the pin to

be inserted. When the 200873 Pin is in position, the 200874

Spacer is placed on the pin and retained with a Cotter pin.

If option "A" has not been chosen, the O-Ring backup ring

351GF-15