Electronic actuated pressure reducing valve, Model – Cla-Val 390-02/3690-02 User Manual

Page 5

Remote

Set-Point

SCADA

Computer

Remote Telemetry Unit

(Customer Supplied)

Optional

Process Variable Transmitter of

Lower Downstream Pressure

(Customer Supplied)

Higher Upstream

Pressure

CLA-VAL

390 Series

Electronic Actuated

Pressure Reducing Valve

with CRD-33 Pilot Control

Flow

CLA-VAL

CRD-33

Control

The Cla-Val 390 Series valves that maintain downstream pressure

and require this pressure to be changed from a remote location. It

can be an effective solution for lowering costs associated with "con-

fined space" requirements by eliminating the need for entry in valve

structure for set-point adjustment. It is also ideal for pressure man-

agement, and can be programmed to minimum night time and opti-

mum daytime pressures. Optional profiler can be used to create cus-

tom correlation between pressure and flow information.

Flow information can also be provided from the main valve, see 133VF.

Additional pilot controls, hydraulic and/or electronic, are also avail-

able to perform multiple functions to fit exact system requirements.

Electronic Actuated

Pressure Reducing Valve

•

Simplified Remote Valve Set-Point Control

•

Isolated Input

•

Ideal for Pressure Management

•

12-24VDC Input Power

•

Reverse Polarity Protection

•

IP-68 (Submersible)

The Cla-Val Model 390-02/3690-02 Electronic Actuated Pressure Reducing

Control Valve combines precise control of field proven Cla-Val hydraulic pilots

and simple, remote valve control. The Cla-Val Model 390-02/3690-02

Pressure Reducing Valve automatically reduces a higher inlet pressure to a

steady lower downstream pressure regardless of changing flow rate and/or

varying inlet pressure. This valve is an accurate, pilot-operated regulator capa-

ble of holding downstream pressure to a pre-determined limit. The valve uses

a CRD-33 pilot control, consisting of a hydraulic pilot and integral controller,

that accepts a remote set-point command input and makes set-point adjust-

ments to the pilot.

The recommended control method is simple remote set-point change from an

RTU (Remote Telemetry Unit) to the CRD-33 where the 4-20 mA command

signal is ranged to specific pressure range. Very accurate control can be

achieved when span does not exceed 100 psi. Since the CRD-33 is pre-

ranged to the full spring range, some on-site calibration may be necessary

when this control method is used. Free downloadable software is available

from Cla-Val website for this purpose. The CRD-33 can also accommodate

control systems where the RTU compares pressure transmitter signal to the

remote set point command signal. The RTU adjusts the CRD-33 with 4-20 mA

command signal containing an adequate deadband to prevent actuator dither-

ing after the two signals agree.

Internal continuous electronic monitoring of actuator position results in virtual-

ly instantaneous position change with no backlash or dithering when control

signal is changed. In the event of a power or control input failure, the CRD-33

pilot remains in hydraulic control virtually assuring system stability under

changing conditions. If check feature ("D") is added, and pressure reversal

occurs, the valve closes to prevent return flow.

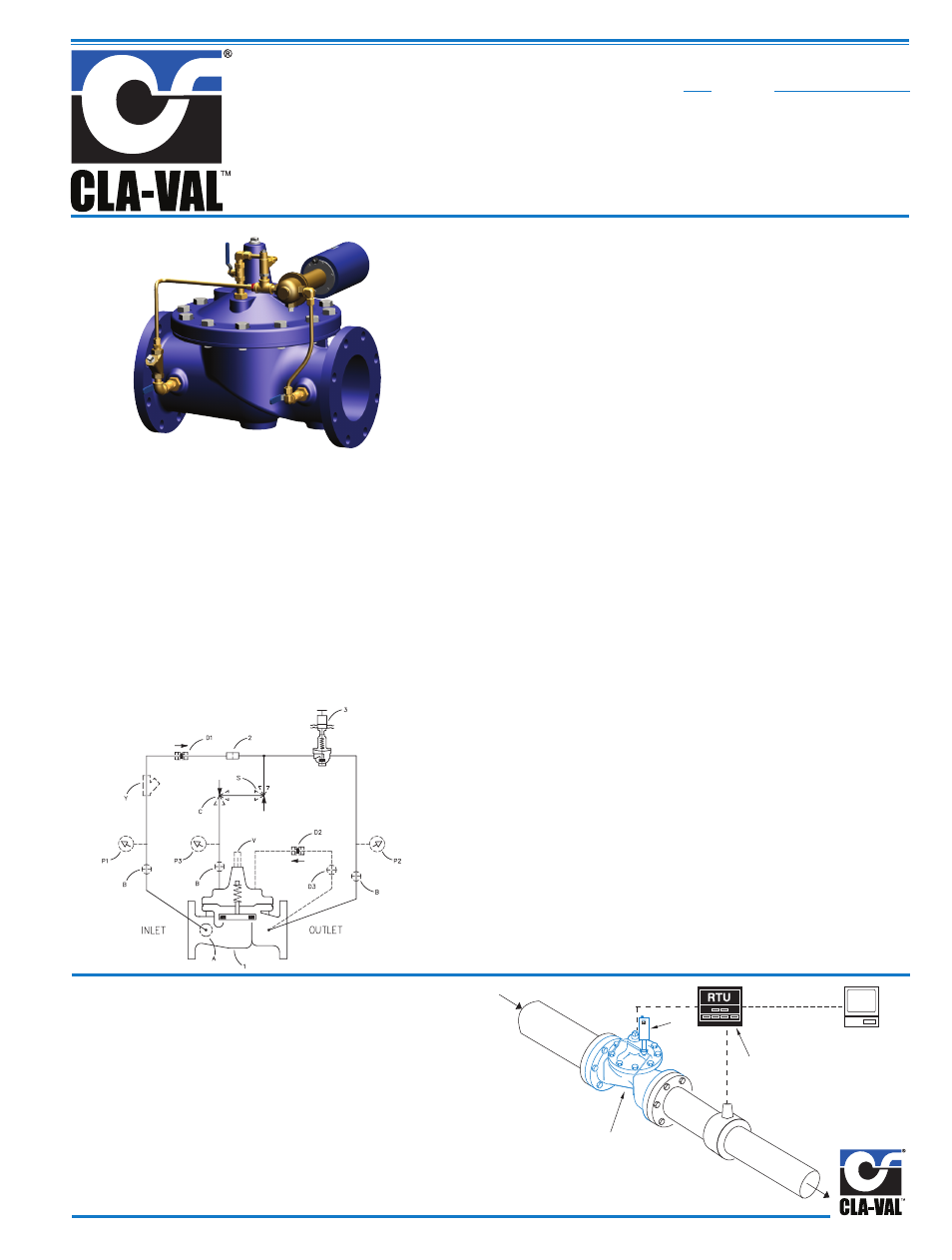

Schematic Diagram

Item Description

1

Hytrol (Main Valve)

2

X58C Restriction Fitting

3

CRD-33 Electronic Pressure Reducing Control

Optional Features

Item Description

A

X46A Flow Clean Strainer

B

CK2 (Isolation Valve)

C

CV Flow Control (Closing)

D

Check Valves with Isolation Valve

P

X141 Pressure Gauge

S CV Flow Control (Opening)

V

X101 Valve Position Indicator

390-02

MODEL

(Full Internal Port)

3690-02

(Reduced Internal Port)

Typical Applications