Cla-val, Dimensions, Service and installation – Cla-Val 61-02/661-02 Technical Manual User Manual

Page 18

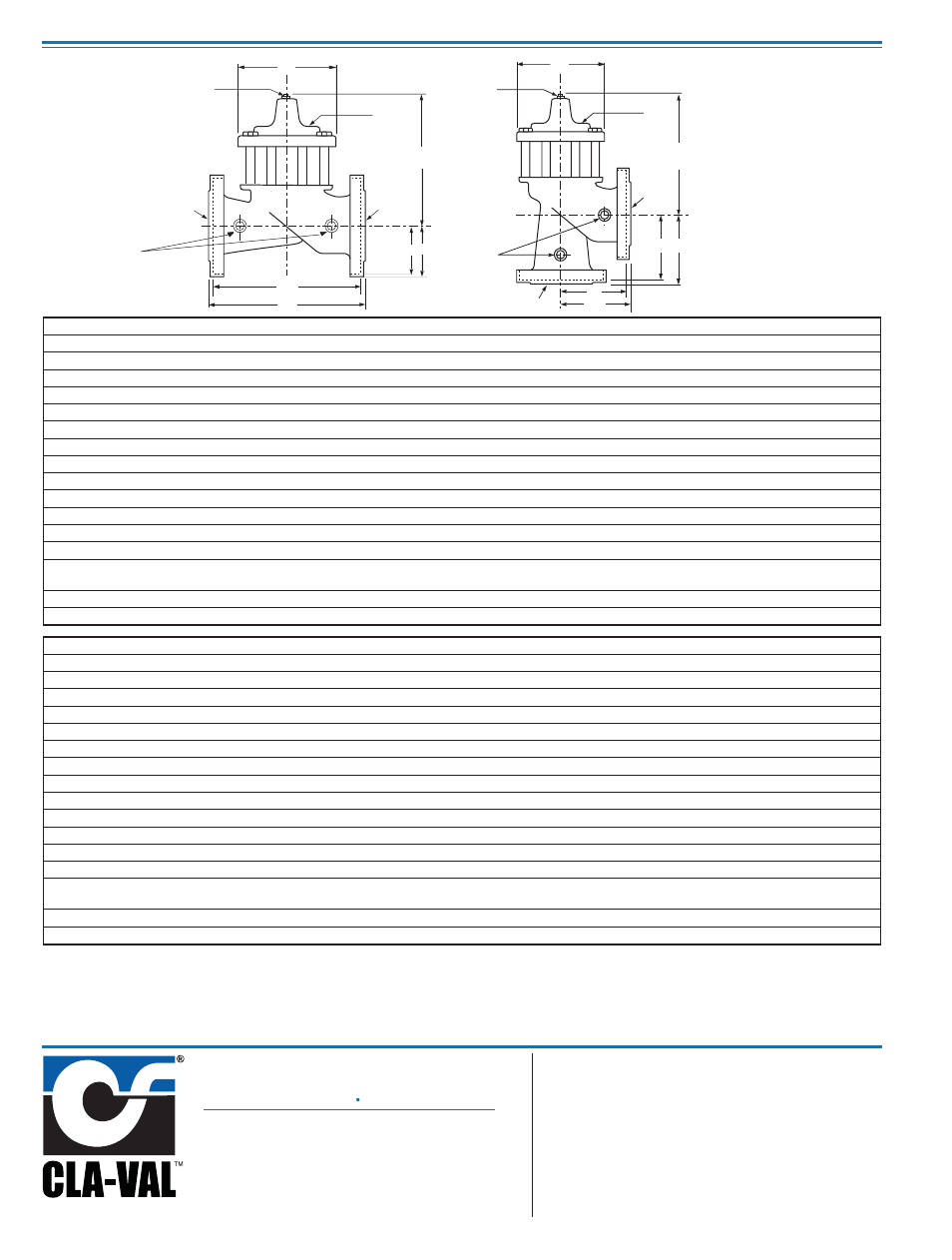

H

K

INLET

OUTLET

D

DD

J

C

E EE

B

100-21 (Angle)

B

H

INLET

K

A

AA

J

C

FF

F

OUTLET

Dimensions

100-21 (Globe)

Service and Installation

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other

positions are acceptable. Due to component size and weight of 10 inch and larger valves, installation with cover UP is advisable. We recommend

isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be

considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend a

thorough inspection be done at least once a year. Consult factory for specific recommendations.

Model 100-21

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800

Fax: 949-548-5441

CLA-VAL

CLA-VAL CANADA

CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada L0R 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©

COPYRIGHT CLA-VAL 2009 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-100-21 (R-11/09)

Represented By:

Valve Size

(Inches)

3

4

6

8

10

12

14

16

18

20

24

30

A 150 ANSI

10.25

13.88

17.75

21.38

26.00

30.00

34.25

35.00

42.12

48.00

48.00

63.25

AA 300 ANSI

11.00

14.50

18.62

22.38

27.38

31.50

—

36.62

43.62

49.62

49.75

—

B Dia.

6.62

9.12

11.50

15.75

20.00

23.62

28.00

28.00

35.44

35.44

35.44

53.19

C Max.

9.25

11.75

15.25

20.25

23.75

27.25

29.31

34.12

35.00

40.25

40.25

56.50

D 150 ANSI

—

6.94

8.88

10.69

—

—

—

—

—

—

—

—

DD 300 ANSI

—

7.25

9.38

11.19

—

—

—

—

—

—

—

—

E 150 ANSI

—

5.50

6.75

7.25

—

—

—

—

—

—

—

—

EE 300 ANSI

—

5.81

7.25

7.75

—

—

—

—

—

—

—

—

F 150 ANSI

3.25

4.50

5.50

6.75

8.00

9.50

11.00

11.75

15.88

14.56

17.00

19.88

FF 300 ANSI

4.12

5.00

6.25

7.50

8.75

10.25

—

12.75

15.88

16.06

19.00

—

H NPT Body Tapping

3

⁄

8

1

⁄

2

3

⁄

4

1

3

⁄

4

1

1

1

1

1

1

1

1

J NPT Cover Center Plug

1

⁄

2

1

⁄

2

3

⁄

4

3

⁄

4

1

1

1

1

⁄

4

1

1

⁄

4

2

2

2

2

K NPT Cover Tapping

3

⁄

8

1

⁄

2

3

⁄

4

3

⁄

4

1

1

1

1

1

1

1

1

Valve Stem Internal

Thread UNF

10-32

1

⁄

4

-28

1

⁄

4

-28

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

1

⁄

2

-20

1

⁄

2

-20

1

⁄

2

-20

3

⁄

4

-16

Stem Travel

0.6

0.8

1.1

1.7

2.3

2.8

3.4

3.4

3.4

4.5

4.5

6.5

Approx. Ship Wt. Lbs.

70

135

230

480

785

1410

2215

2215

2300

3400

3600

7700

Valve Size

(mm)

80

100

150

200

250

300

350

400

450

500

600

750

A 150 ANSI

260

353

451

543

660

762

870

889

1070

1219

1219

1607

AA 300 ANSI

279

368

473

568

695

800

—

930

1108

1260

1264

—

B Dia.

168

232

292

400

508

600

711

711

900

900

900

1351

C Max.

235

298

387

514

603

692

744

867

889

1022

1022

1435

D 150 ANSI

—

176

226

272

—

—

—

—

—

—

—

—

DD 300 ANSI

—

184

238

284

—

—

—

—

—

—

—

—

E 150 ANSI

—

140

171

184

—

—

—

—

—

—

—

—

EE 300 ANSI

—

148

184

197

—

—

—

—

—

—

—

—

F 150 ANSI

95

114

140

171

203

241

279

298

403

370

432

505

FF 300 ANSI

105

127

159

191

222

260

—

324

403

408

483

—

H NPT Body Tapping

3

⁄

8

1

⁄

2

3

⁄

4

1

3

⁄

4

1

1

1

1

1

1

1

1

J NPT Cover Center Plug

1

⁄

2

1

⁄

2

3

⁄

4

3

⁄

4

1

1

1

1

⁄

4

1

1

⁄

4

2

2

2

2

K NPT Cover Tapping

3

⁄

8

1

⁄

2

3

⁄

4

3

⁄

4

1

1

1

1

1

1

1

1

Valve Stem Internal

Thread UNF

10-32

1

⁄

4

-28

1

⁄

4

-28

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

3

⁄

8

-24

1

⁄

2

-20

1

⁄

2

-20

1

⁄

2

-20

3

⁄

4

-16

Stem Travel

15

20

28

43

58

71

86

86

86

114

114

165

Approx. Ship Wt. Kgs

32

61

104

218

356

640

1006

1006

1044

1544

1634

3496