Cla-Val 61-02/661-02 Technical Manual User Manual

Page 10

FREEDOM OF MOVEMENT

The following procedures can be used to determine if the

valve opens and closes fully. During this test the diaphragm

can be checked for damage.

1.The Powertrol Valve will have a control to open and close

the valve. Position the control so that pressure is applied to

the cover chamber (above the valve diaphragm). This will

close the Powertrol Valve. Check the drain from the control

that discharges to atmosphere.

Once the liquid from the lower diaphragm chamber is drained

the discharge should stop. If the discharge continues after the

normal time it takes to drain then the diaphragm is damaged,

or the stem nut is loose, or the stem o-ring is leaking. If the

discharge is continuous from both chambers then there is a

possibility that the diaphragm or the pilot control is damaged.

If the valve is equipped with a "Dry Drain" (control drain piped

to downstream end of the valve) then same procedure is fol-

lowed except the CK2 Shutoff Cock on the downstream end

of the valve must be closed and the drain line disconnected

and drained to atmosphere. It can then be checked as above.

Measurement of the vertical travel of the stem (diaphragm

assembly) will make it possible to determine if the travel, or

stroke is restricted. The following chart provides this mea-

surement. It is necessary to have either the X101 Valve

Position Indicator or X105 Limit Switch Assembly installed on

the valve to visually check the travel.

Mark the position of the stem on the X101 or X105 when the

valve is closed. Reposition the control so that pressure is

applied below the diaphragm and the cover chamber is

drained. Determine the extent of the stem travel. Check this

movement with the stem travel chart. If the stroke is different

than listed (5% to 10%) then there is good reason to believe

something is mechanically restricting the stroke of the valve

at one end of its travel. If it is determined that flow does not

stop through the valve when in the indicated "closed" position,

the obstruction probably is between the disc and the seat, or

in the power unit chamber below the diaphragm. If the flow

stops, the obstruction is likely in the cover chamber above the

diaphragm or possibly above the disc retainer. Refer to the

sectional view under Principle of Operation.

If operation of the valve a few times does not dislodge the for-

eign object obstructing the diaphragm assembly (stem) move-

ment then the valve must be disassembled and the problem

located and corrected. See disassembly instructions.

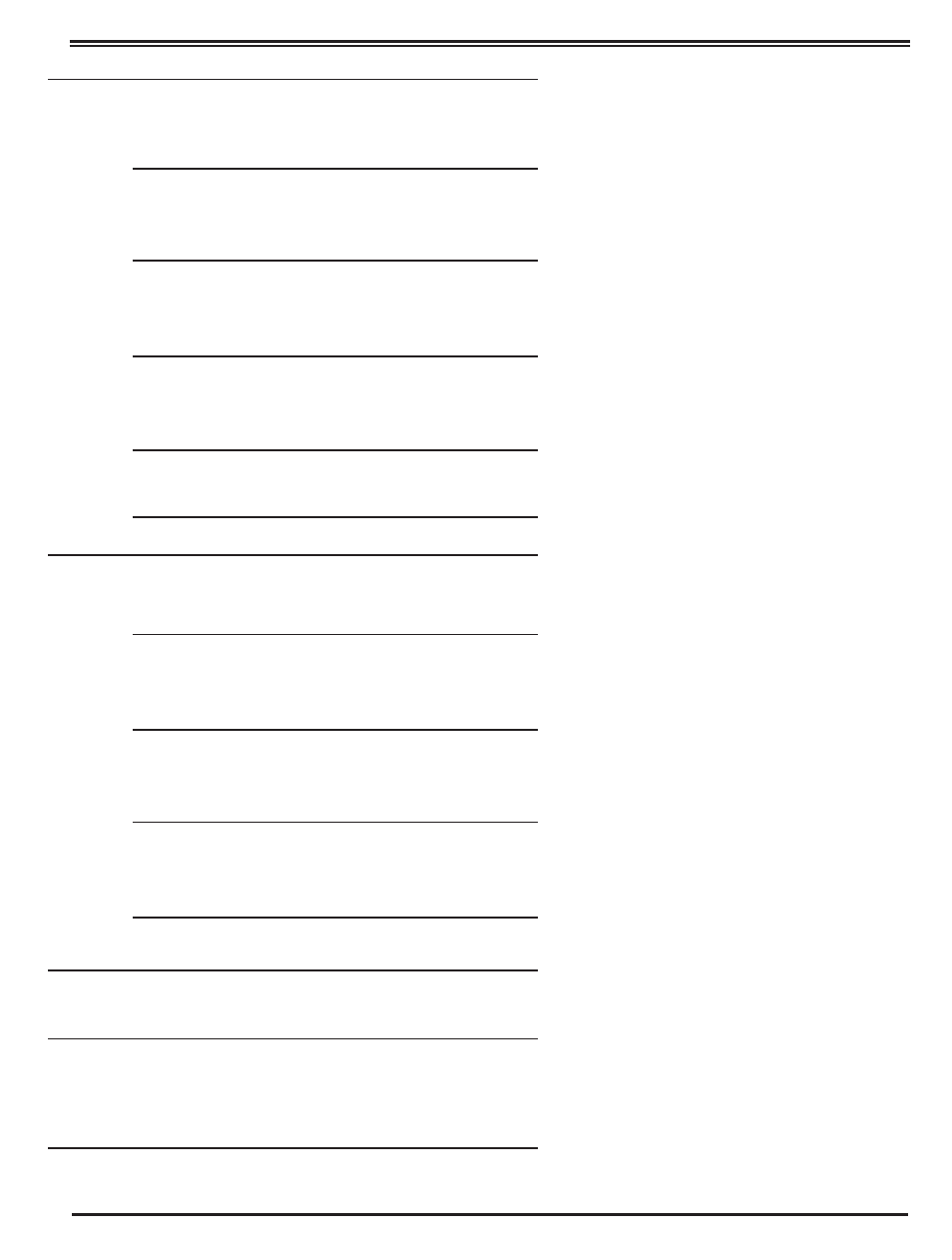

INCHES

1

1 1/4

1 1/2

2

2 1/2

3

4

6

8

10

12

14

16

MM

25

32

40

50

65

80

100

150

200

250

300

350

400

INCHES

0.3

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

3.9

4.5

MM

8

10

10

15

18

20

23

43

58

71

86

99

114

SYMPTOM

Valve fails to

close.

Valve fails to

open.

Valve closes but

leakage occurs.

O-Ring failure

*POSSIBLE

CAUSE

Stem stuck in open position.

Worn diaphragm

or loose upper

stem nut

Foreign object on

valve seat.

Pressure not being

released from power

unit chamber.

Operating

pressure not

getting into valve

cover.

Insufficient

line pressure.

Stem stuck in

closed or semi-

open position.

Worn diaphragm

or loose upper

stem nut.

Foreign object on

top of disc retainer

Pressure not being

released from

cover chamber.

Operating pressure not

applied into power

unit chamber.

Worn disc or seat.

Mineral deposits

on stem cause

abrasion on ring.

TEST

PROCEDURE

Vent power unit cham-

ber. Apply pressure to

cover chamber. Valve

should close.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow from

cover indicates this

trouble.

Valve opens okay but

only closes part way.

Make sure

pressure is being

released by opening a

fitting into the cham-

ber. If valve then clos-

es refer to remedy.

Use pressure gauge

or loosen cover plug

to check for pressure.

Check line pressure.

Vent cover. Apply

pressure to power unit

chamber.

Apply pressure in

power unit chamber

and vent cover.

Continuous flow from

cover indicates this

pro bleary.

Valve closed okay

but won't open all

the way.

Open a fitting or

remove a plug from

cover chamber if

cover chamber vents

and valve opens, see

remedy.

Loosen a fitting in this

chamber to check for

pressure at this point.

The best procedure

here is to disassemble

the valve and inspect

these parts.

Remove pressure

from both cover and

power unit chambers

and apply line pres-

sure to valve. Open

line from power unit

chamber and observe

continuos flow.

REMEDY

Disassemble, examine

all internal parts for

cause of the sticking

condition and clean off

scale deposits.

Disassemble and

replace diaphragm or

tighten the valve stem

nut.

Try operating valve a

few times. This might

dislodge the object. If

this fails, disassemble

and remove the

obstruction.

Check control

system. Tube line or

nipple might be plugged

up.

Clean tubing or pipe fit-

tings into cover cham-

ber. Open CK2 Isolation

Valve in control lines.

Establish line pressure.

Disassemble, examine

all internal parts for

cause of the sticking

pro bleary, and clean off

scale deposits.

Disassemble and

replace diaphragm or

tighten valve stem nut.

Try operating valve a

few times. This might

dislodge the object. if

this fails disassemble

and remove the

obstruction.

Check control system.

Check lines or pipe fit-

tings. Clean out any

plugged lines.

Clean tubing or pipe fit-

tings into power unit

chamber.

Replace worn parts.

Disassemble and

replace O-ring.

*Assuming control system is functioning properly.

STEM TRAVEL

(Fully open to fully closed)

VALVE SIZE

VALVE SIZE