Cla-Val 61-02/661-02 Technical Manual User Manual

Page 12

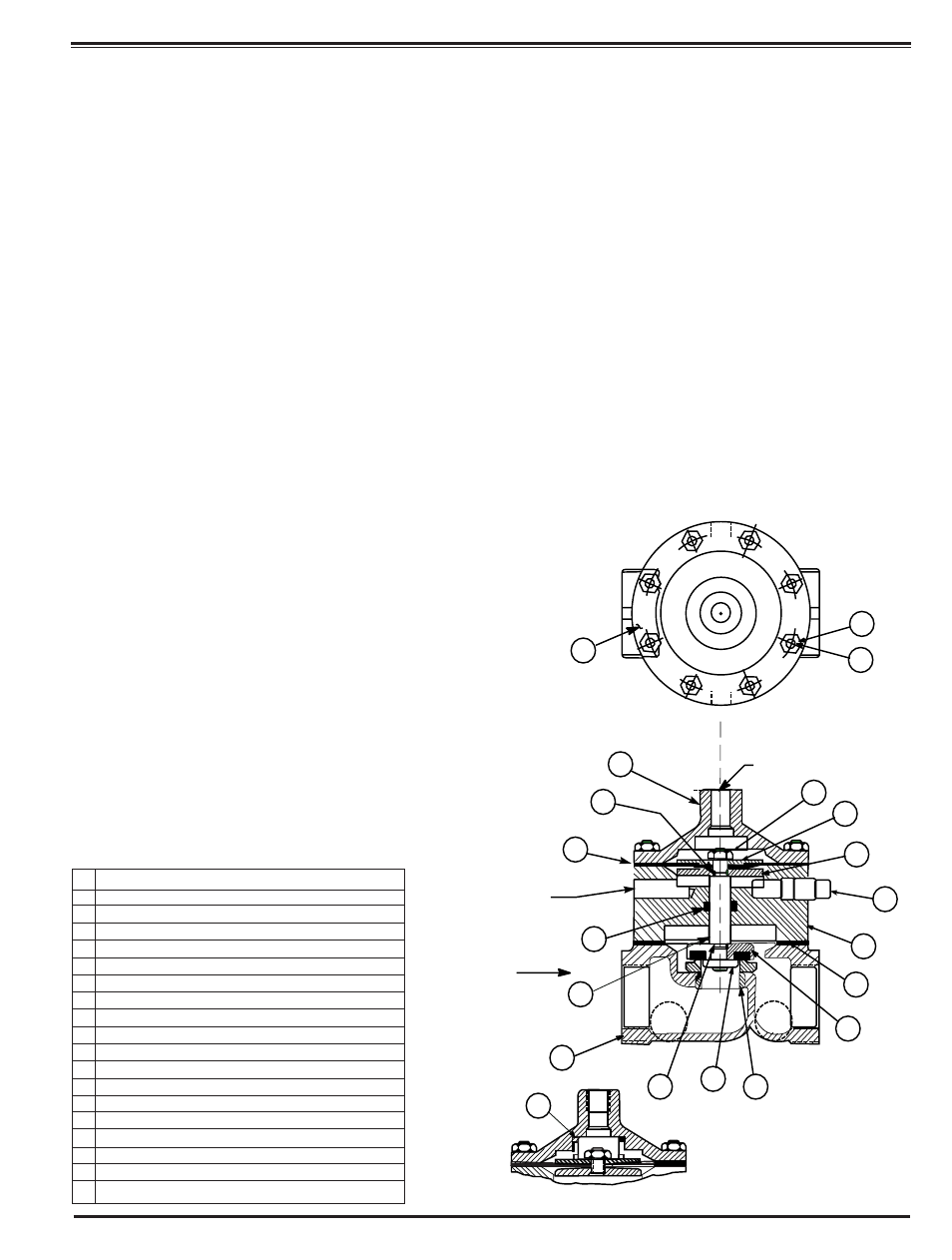

INLETIN

L

E

T

1/8 NPT (THESE

TAPPED HOLES ARE

SHOWN 90" FROM

TRUE POSITION)

INLET

MODELS 100-02KH 100-02KHR, 100-02KHX

16

19

2

17

6

11

8

15

17

9

18

10

12

3

14

7

5

4

13

1

1/8 NPT

1. If the disc has been removed, it is important that correct

pressure be on the disc from the disc guide when the lower

stem nut is tight. Use sufficient spacer washers to obtain

slight pressure (by visual indention) on the disc. Indention

should be slight and no looseness evident. This adjust-

ment applies to 1 " through 16". Refer to seat and disc

detail drawings for location of spacer washers for various

valve sizes.

NOTE: New discs will usually require a different number of

spacer washers to obtain the right amount of "grip'' on the

disc.

2. The stem, with the disc assembly, can now be inserted

through the power unit body. Note sectional view for cor-

rect position of the power unit body and stem assembly

3. Install on the cover end of the stem the lower diaphragm

washer,the diaphragm, the upper diaphragm washer, then

screw on the upper stem nut.

4. Tighten the upper stem nut securely so the diaphragm

and upper and lower diaphragm washer cannot be turned

on the stem. During the tightening of the upper stem nut

the lower stem nut can be held in a vice, or with a second

wrench.

5. Replace the gasket on the body. If an o-ring seal is used

as a gasket, valve size 4" through 16", a light coating of

grease can be applied to the power unit body groove to

hold the o-ring in place while installing on the body. The

power unit body must be replaced so that the index marks

applied in Disassembly Step 1 align. The control tubing will

then be able to be reassembled without difficulty.

6. Replace cover chamber spring on the upper diaphragm

washer. NOTE: Some valves may not have a cover cham-

ber spring.

7. Place the cover on the power unit body aligning the

index marks. Secure the cover with 8 stud nuts. Tighten

the nuts firmly with a cross-over pattern until all nuts are

tight:

8. Reinstall the control system and tubing exactly as it was

before disassembly.

9.The Powertrol Valve can be tested for tight closure as well as

the tightness of the seal across the diaphragm.

a.The downstream or outlet shutoff valve remains closed

b. If the control system has a pilot or control that can position the

valve to a closed position, put the control in a position to close

the Powertrol. Lacking a control, inlet pressure must be tubed to

the Powertrol cover.

c. Open upstream gate or line block valve just enough to allow

flow.

d. Have the power unit body, center section, open to atmosphere

The power unit body will be atmospheric if the control is being

used.

e. Partially disconnect a fitting on the discharge side of the valve.

Do not remove fully unless there is no pressure.

f. After the valve is in the closed position for a few minutes, all

draining of the power unit body should stop. This will indicate a

good seal across the valve seat and the diaphragm.

100-02 POWERTROL

VALVE SIZES 1/2" & 3/4"

1

HEX NUT 10-32 (8)

2 COVER

3 POWER UNIT BODY

4 HEX NUT 1/4-28-NF-2 A.S.F. JAM

5

DIAPHRAGM WASHER (UPPER)

6

DIAPHRAGM

7

DIAPHRAGM WASHER (LOWER)

8

STEM

9

DISC GUIDE

10 DISC RETAINER ASSEMBLY

11 "O" RING

12 BODY TO BODY GASKET

13 STUD 10-32 (8)

14 PIPE PLUG 1/8 NPT

15 BODY

16 SPRING (USED ON 100-02KHR & 100-02 KHX

17 "O" RING

18 SEAT

19 NAMEPLATE

ITEM

NO.

DESCRIPTION