Installation and maintenance instructions, Bulletin 8320 – Cla-Val 136-03/636-03 Technical Manual User Manual

Page 19

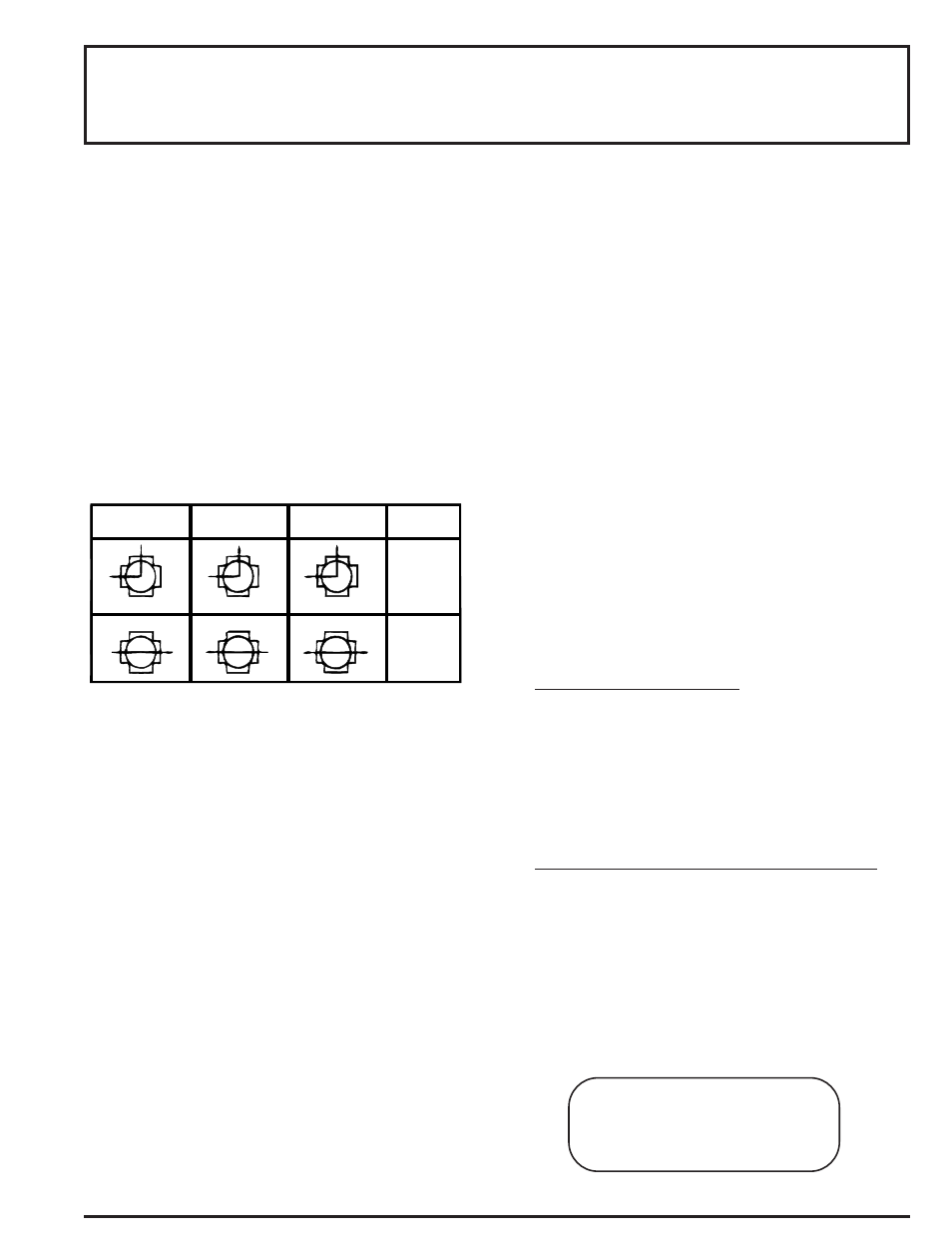

NORMALLY OPEN

PRESS AT 3 (C)

NORMALLY CLOSED

PRESS AT 3 (C)

UNIVERSAL-PRESS

AT ANY ORIFICE.

FORM

SOLENOID

DE-

ENERGIZED

SOLENOID

ENERGIZED

3

I

(C)

2

(B)

(A)

3

I

(C)

2

(B)

(A)

3

I

(C)

2

(B)

(A)

3

I

(C)

2

(B)

(A)

3

I

(C)

2

(B)

(A)

3

I

(C)

2

(B)

(A)

DESCRIPTION

MANUAL OPERATORS (OPTIONAL)

NOTE: Port Markings 1, 2, and 3 correspond directly to A,

B and C.

Bulletin 8320 is a small 3-way solenoid operated valve with all three

pipe connections located in the body. The bodies are of brass or stain-

less steel construction. Standard valves have General Purpose, Nema

Type 1 Solenoid Enclosures. Valves that are equipped with a solenoid

enclosure which is designed to meet Nema Type 4-Water tight, Nema

Type 7 (C or D) Hazardous Locations - Class I, Group C or D, and

Nema Type 9 (E, F or G) Hazardous Locations - Class II, Group E, F or

G are shown on separate sheets of Installation and Maintenance

Instructions, Form Numbers V-5391 and V-5381.

Check Nameplate for correct Catalog Number, pressure, voltage and

service.

Valves with suffix "MO" or "MS" in catalog number are provided with a

Manual Operator which allows manual operation when desired or dur-

ing an interruption of electrical power.

INSTALLATION

Valve may be mounted in any position

POSITIONING

Connect piping to valve according to markings on valve body. Refer to

Flow Diagram provided. Apply pipe compound sparingly to male pipe

threads only; if applied to valve threads, it may enter valve and cause

operational difficulty. Pipe strain should be avoided by proper support

and alignment of piping. When tightening pipe, do not use valve as

lever.

PIPING

Wiring must comply with local and National Electrical Codes. For

valves equipped with an explosion-proof, watertight solenoid enclo-

sure, the electrical fittings must be approved for use in the approved

hazardous locations. Housings for all solenoids are made with connec-

tions for 1/2 inch conduit. The general purpose enclosure may be rotat-

ed to facilitate wiring by removing the retaining cap.

WIRING

OPERATION

Normally Closed: Applies pressure when solenoid is energized:

exhausts pressure when solenoid is de-energized

Normally Open: Applies pressure when solenoid is de-energized;

exhausts pressure when solenoid is energized.

Universal: For normally closed or normally open operation, selection

or diversion of pressure can be applied at port 1 (A), 2 (B), or 3 (C).

NOTE

SOLENOID TEMPERATURE

MAINTENANCE

COIL REPLACEMENT

(REF. FIG. 2)

Alternating Current (A-C) and Direct Current (D-C) solenoids are built

differently. To convert from one to other, it is necessary to change the

complete solenoid, including the core assembly.

Turn off electrical power, disconnect coil lead wires and proceed as

follows:

Spare Parts Kits and Coils are available for ASCO valves. Parts

marked with

Standard catalog valves are supplied with coils designed for contin-

uous duty service. When the solenoid is energized for a long period,

the solenoid enclosure becomes hot and can be touched with the

bare hand for only an instant. This safe operating temperature. Any

excessive heating will be indicated by the smoke and odor of burn-

ing coil insulation.

CLEANING

A periodic cleaning of all valves is desirable. The time between

cleanings will vary, depending on the media and service conditions.

In general, if the voltage to the coils is correct, sluggish valve oper-

ation or excessive leakage will indicate that cleaning is required.

IMPROPER OPERATION

Faulty Control Circuit: Check the electrical system by energiz-

ing the solenoid. A metallic click signifies the solenoid is operat-

ing. Absence of the click indicate loss of power supply. Check for

loose or blown-out fuses, open-circuited or grounded coil, broken

lead wires or splice.

Burned-out Coil: Check for open-circuited coil. Replace coil, if

necessary.

Low Voltage: Check voltage across coil leads. Voltage must be

at least 85% of nameplate ratings.

Incorrect Pressure: Check valve pressure. Pressure to valve

must be within the range specified on nameplate.

Excessive Leakage: Disassemble valve and clean all parts.

Replace parts that are worn or damaged with a complete Spare

Parts Kit for best results.

Turn off electrical power supply and de-pressurize valve.

VALVE DISASSEMBLY AND REASSEMBLY

(REF. FIG. 2)

WARNING:

Turn off electrical power and line pressure to valve

before making repairs. It is not necessary to remove valve from

pipe line for repairs.

1.

2.

3.

4.

5.

Remove retaining cap, nameplate and cover.

Slip yoke containing coil, sleeves and insulating washers off the

solenoid base sub-assembly. Insulating washers are omitted

when molded coil is used. In some D.C. Constructions, a single

flux plate over the coil replaces yoke, sleeves and insulating

washers.

Reassemble in reverse order of disassembly.

1.

2.

3.

Remove retaining cap and slip entire solenoid off solenoid base

subassembly or plugnut/core tube sub-assembly.

Unscrew bonnet or solenoid base sub-assembly. Remove core

assembly, core spring and body gasket.

Remove end cap, body gasket, disc spring, disc holder, disc or

disc holder assembly.

All parts are now accessible for cleaning or replacement.

Replace worn or damaged parts with a complete Spare Parts Kit

for best results.

Reassemble in reverse order of disassembly paying careful

attention to exploded view provided.

1.

2.

3.

4.

5.

ORDERING INFORMATION FOR SPARE

PARTS KITS

When Ordering Spare Parts Kits or Coils

Specify Valve Catalog Number,

Serial Number and Voltage

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

3-WAY SOLENOID VALVES, NORMALLY OPEN

NORMALLY CLOSED AND UNIVERSAL CONSTRUCTION

IMPORTANT:

For protection of the solenoid valve, install a strainer

or filter suitable for the service involved in the inlet side as close to

the valve as possible. Periodic cleaning is required depending on the

service conditions.

BULLETIN

8320

ASCO

FORM NO. V5291R2