Spencer Single-Stage Scroll Blowers User Manual

Page 6

6

Instructions for Disassembly and Reassembly

Caution: Parts must be reassembled in exactly

the same relative positions. Therefore, it is

recommended that each part be tagged as it is

removed from the machine to facilitate later

reassembly. It is especially important that the

impeller location and its position on the shaft be

marked.

Balancing

Each machine is fully tested before leaving the

Spencer factory to be sure vibrations, if any, are well

within specifications for that particular machine.

However, rough handling during shipment or

improper disassembly/reassembly of a machine can

upset its balance and result in excess vibration.

When a machine is being disassembled for repairs,

mark the parts as they are removed. If this is done,

no trouble should be expected from vibration when

they are reassembled in the same order.

However, if the impeller is being replaced or there is

any vibration due to an unbalanced condition after

assembly, use the following procedure.

Run the unit at maximum speed. Mark the position

of the impeller hub on the shaft. Loosen the bolts or

screws holding the impeller on the shaft. Rotate the

impeller 90˚ on the shaft. Run the machine again at

the maximum speed, and check the vibration.

Repeat this process until the best position is located

for the impeller on the shaft so that there is no

vibration or unbalance in the machine.

Disassembly

Scroll blowers are now being supplied with casing,

motor base and casing/base support welded into a

integral unit. This innovation provides a stable and

maintenance free platform. As a result, maintenance

is confined to removal of the motor on one end and

• Is the control panel energized?

• Have maintenance and operations personnel

been notified?

CAUTION: This blower must have adequate

system resistance at all times to avoid operation

at or near free delivery (wide open). It Is typically

imposed by the process and supplemented with

a throttling valve. Running the blower overloaded

will damage the motor.

Start Up

Caution: It is very important that the blower be

installed with regard to the correct direction of

rotation. A direction-of-rotation arrow is affixed

to the scroll casing.

Under no circumstances should the Scroll

Blower be operated without being connected to

the pipe system with which it is to be used.

When starting up a Scroll Blower it is

recommended that the blast gate or other control

device be closed. When first starting the installation,

an ammeter should be connected to the motor circuit

and the control device opened until full load current

is reached. At this point, the unit is delivering the full

rated volume of air for which it was designed and the

control device should be adjusted to prevent opening

beyond this point. (See following paragraphs.)

Multiple Machine Operation

Caution: All Scroll Blowers in a multiple machine

operation should be operated periodically. This

can be accomplished through bi-weekly,

alternate operation of the machines.

Check valves must be installed in the discharge of

each Scroll Blower to prevent blow-back through the

unit not in operation. These are available as optional

equipment.

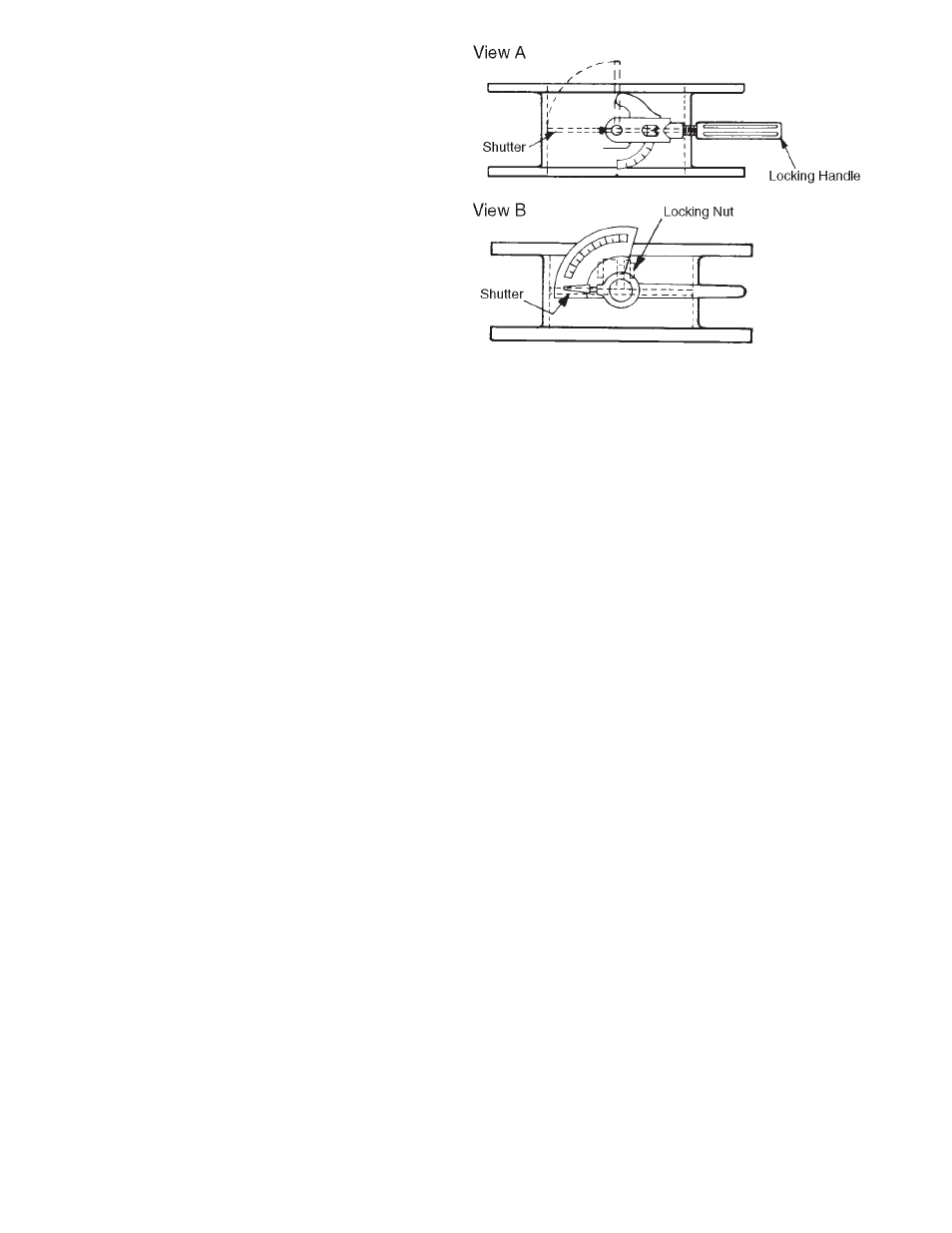

When operating two or more Scroll Blowers in

parallel it is necessary to be sure that each machine

carries its respective share of the load. This is

accomplished by setting each blast gate so that the

Scroll Blower operates within the full load amp rating

of its motor. Once the proper setting is established,

tighten bolts securing the variable stop (View A) or

the locking nut (View B). This prevents the blast gate

from being opened beyond the full load rating of the

motor.

The Spencer Turbine Company ◆ 600 Day Hill Road, Windsor, CT 06095 ◆ TEL 800-232-4321 ◆ 860-688-8361 ◆ www.spencerturbine.com