Spencer Single-Stage Scroll Blowers User Manual

Page 4

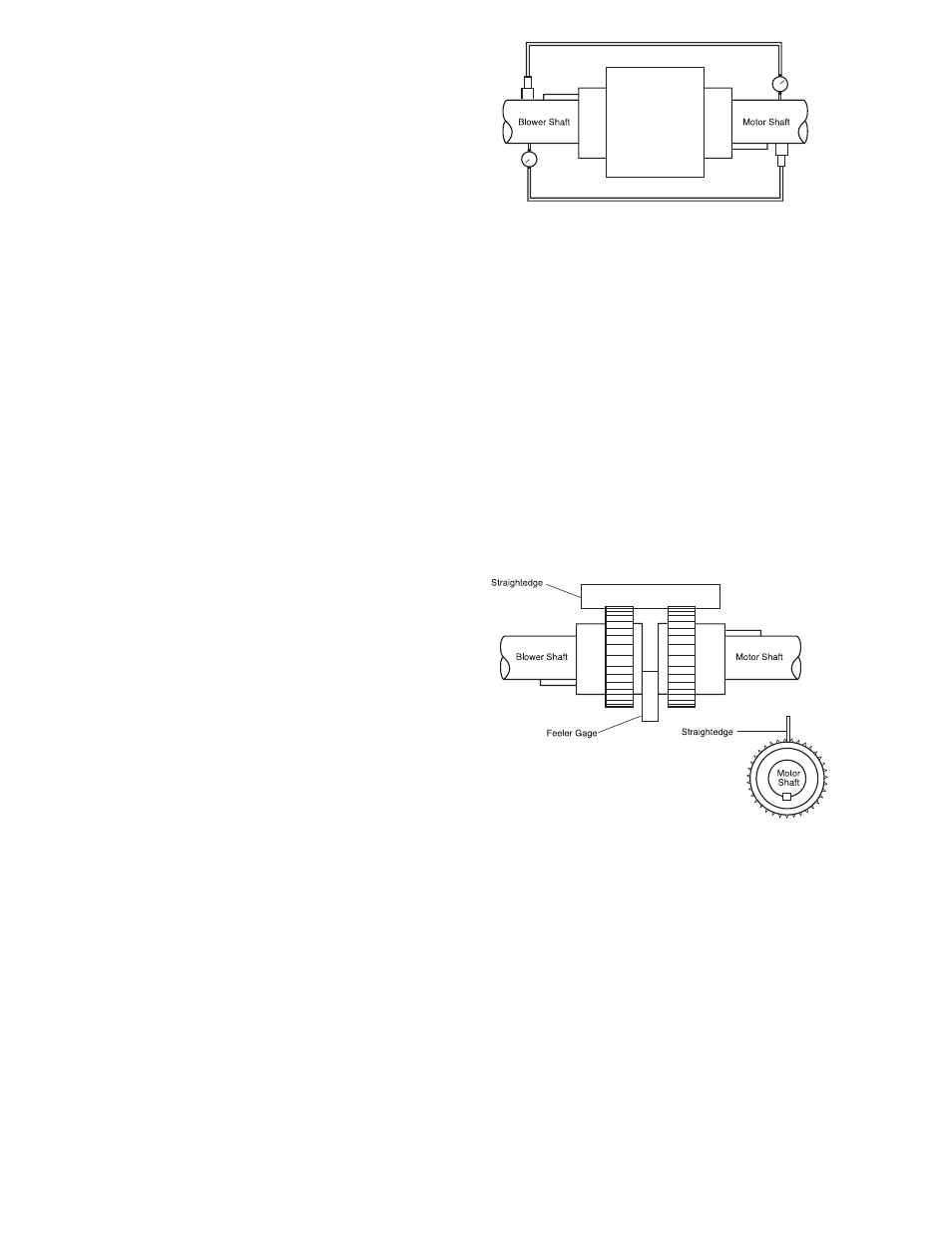

Coupling alignment lines up the motor shaft and

blower shaft in horizontal and vertical planes. It also

ensures an adequate clearance (gap) between the

two coupling halves. Only qualified personnel should

attempt to align a coupling. If problems arise, contact

Spencer or your Spencer Representative.

Sier Bath Gear-Type Couplings, manufactured to

our rigid specifications, are most commonly supplied

with Spencer equipment.

Sier Bath

Hub to Hub

Coupling Size, In.

Gap, ln.

7/8

1/8

1-1/2

1/8

2

1/8

2-1/2

1/4

3

1/4

3-1/2

1/4

4

1/4

4-1/2

1/4

5

1/4

Remove one snap ring and slide the sleeve off the

hub halves. Using a feeler gage, verify that the gap

between the coupling halves agrees with this table.

Caution: Some motor shafts are spring-loaded

axially. Be careful when using the feeler gage to

avoid compressing the shaft and disturbing the

normal at-rest position.

Machinery Soft Foot

Imperfections or unevenness between the machine

base and any foot of the motor or blower creates a

condition known as soft foot, which may be parallel

or angular. If uncorrected, soft foot leads to increased

stress and high vibration. Although both the motor

and blower feet were preset at the factory, each foot

must be checked for soft foot prior to alignment. Any

vertical or angular soft foot that exceeds .003" is

excessive and must be corrected.

Laser Alignment Technique (Recommended)

Laser systems have significant advantages such as

reduced maintenance costs and energy consumption;

prolonged life for bearings, seals and couplings;

decreased bearing temperatures and lower vibration

levels. Many laser systems also identify and measure

soft foot conditions.

NOTE: Consult an alignment specialist if laser

equipment is not available.

Reverse Indicator Method (Permissible)

This method may be done electronically following

the instrument manufacturer's instructions or by

means of dial indicators as follows:

1. Reinstall the coupling sleeve, seal and snap ring.

2. Clamp dial indicators on shafts 180° apart as

shown.

3. Place indicator probes on opposite shafts as

shown.

4. Rotate both shafts simultaneously in the correct

operating direction, taking readings at 90°

intervals.

5. Adjust motor to achieve parallel and angular

alignment. If questions arise, contact the Spencer

Service Department.

Straightedge Method (Permissible)

1. Remove old lubricant and clean the hub teeth.

2. Set a machine shop quality straightedge across

the coupling hubs (at the root diameter of the

gear teeth).

3. Adjust the motor so the straightedge is evenly

supported between the coupling hubs at the 3, 6,

9 and 12 o'clock positions.

4. Using a feeler gage, measure the clearance

between the coupling hubs at the 3, 6, 9 and 12

o'clock positions.

5. Adjust the motor so the gap is identical at all four

positions and in accord with the table of hub to

hub gaps.

4

The Spencer Turbine Company ◆ 600 Day Hill Road, Windsor, CT 06095 ◆ TEL 800-232-4321 ◆ 860-688-8361 ◆ www.spencerturbine.com