Spencer Bearing Installation Tool User Manual

Instructions, Spencer, Bearing installation tool

Form BT

Instructions

Use the Spencer Bearing Installation Tool and the

following instructions to properly align and install both

radial and thrust bearings.

Caution: Maintain extreme cleanliness to avoid

bearing contamination. Use new gaskets to prevent

leakage.

Caution: Never hammer or use excessive force for

bearing installation. The use of heat for bearing

installation is not required.

1. Apply a light coat of oil to the bearing housing

bore, shaft journal and bearing.

2. Start the bearing on the shaft journal according

to the bearing instruction sheet. NOTE: If the

assembly is equipped with a bronze rotation shaft

seal, start the seal on the shaft but do not seat.

3. Screw threaded rod into the end of the blower shaft.

4. Choose the correct pusher, corresponding to the

bearing number.

5. Fit the pusher into the end of the bearing tool body.

6. Slide bearing tool body and pusher onto the steel rod

with pusher resting against the bearing.

7. While holding the pusher and body assembly against

bearing, slide the follower onto threaded rod and fit

into body.

8. Slide the handle and thrust washer onto the rod

against the follower.

9. Finally, thread the nut firmly against the thrust washer.

Make sure everything is lined up and centered.

10. While holding the handle, press the bearing on until it

is tight, making sure bearing seats against the shaft

shoulder.

Spencer

®

Bearing Installation Tool

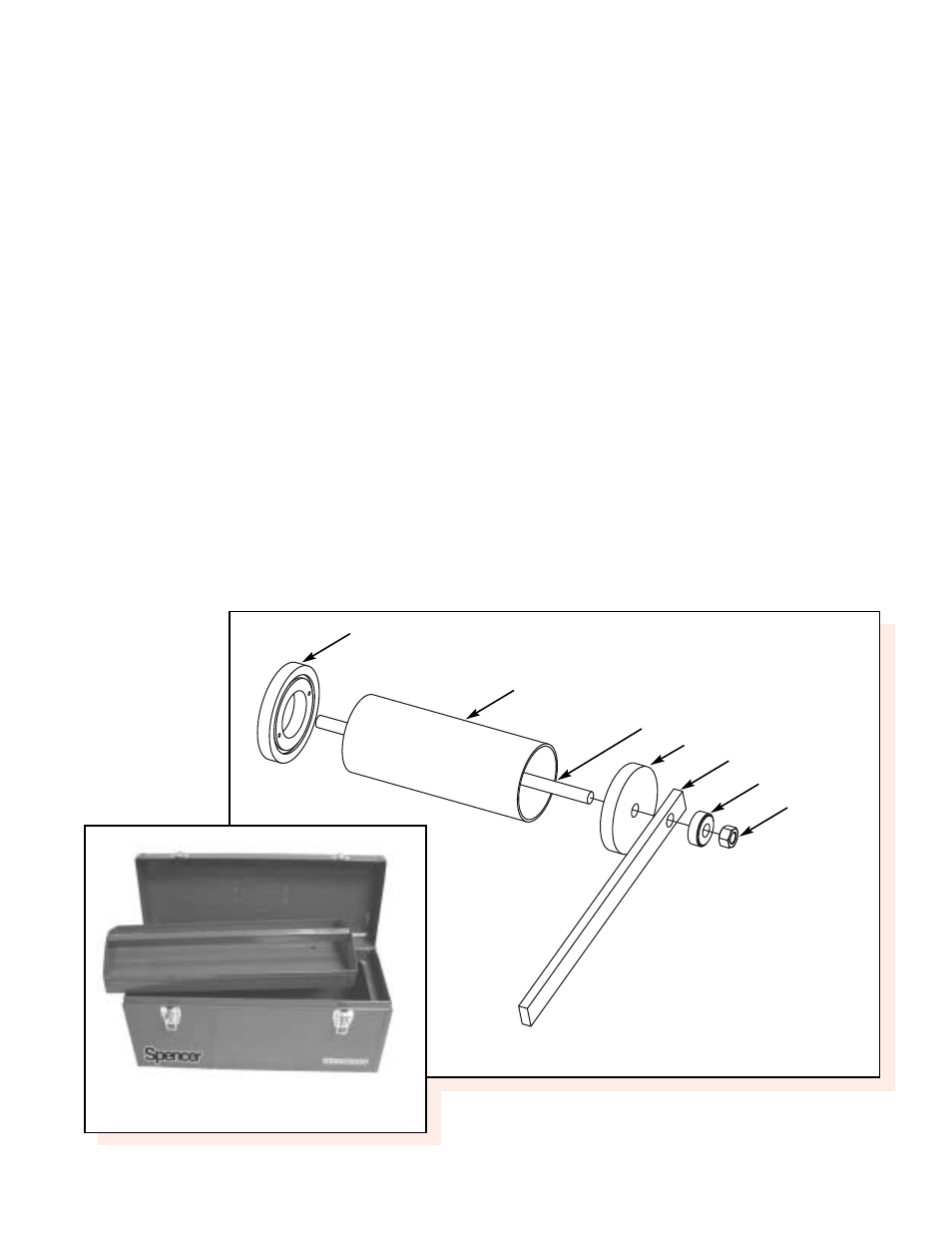

Bearing Installation Tool

Bushing

Body

Threaded Rod

Follower

Handle

Thrust Washer

Hex Nut

The Spencer Turbine Company, 600 Day Hill Road, Windsor, CT 06095-4706

◆

TEL 800-232-4321

◆

860-688-8361

◆

FAX 860-688-0098

◆

www.spencerturbine.com

Tool Box