Spencer Single-Stage Scroll Blowers User Manual

Page 3

3

The Spencer Turbine Company ◆ 600 Day Hill Road, Windsor, CT 06095 ◆ TEL 800-232-4321 ◆ 860-688-8361 ◆ www.spencerturbine.com

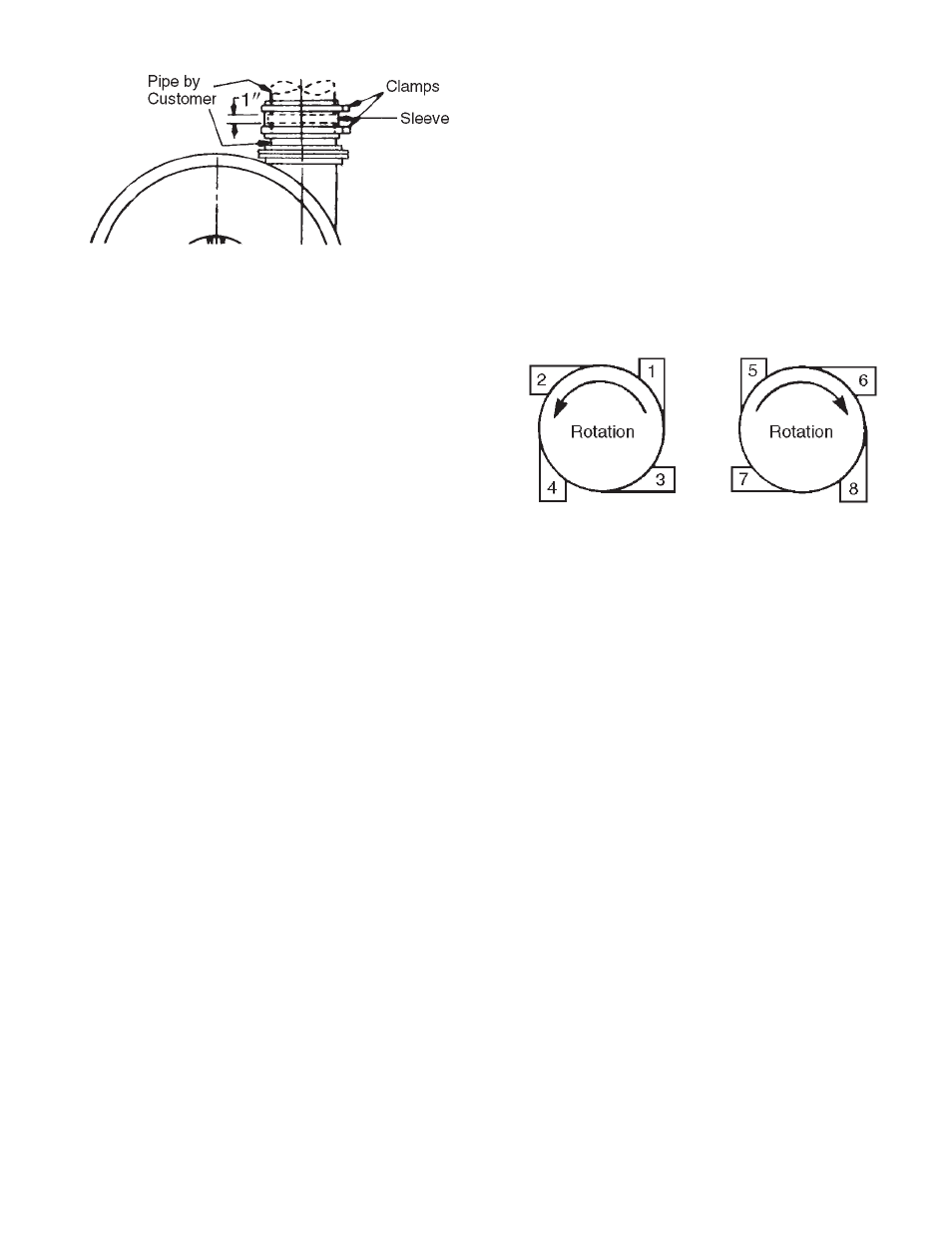

The rubber connecting sleeve supplied with the scroll

should be installed so that it covers a gap of

approximately one inch as illustrated. The mounting

clamps supplied with the sleeve should be

adequately tightened to effect an air-tight connection.

Electrical

Caution: Be sure motor, starter, controls and

other electrical equipment is the proper type

suitable for the application and environment and

complies with all applicable codes.

Be sure that the motor furnished with this machine is

wound for the same type of voltage available at the

installation site. In making the electrical connections,

follow the wiring instructions furnished. Wire and

fuses should be of ample capacity to insure that

proper voltage is maintained at the motor terminals

while starting and running. It is important that proper

starting equipment be used. All AC machines should

be equipped with a magnetic contactor or a manual

or automatic compensator depending on the machine

size and the installation regulations of the local

power company. The starters should have thermal

overload protection as well as true low-voltage

protection.

Air Filters

The Spencer Turbine Company recommends the

use of inlet air filters on all Scroll Blowers for

pressure applications.

The use of any type of filter requires that it

be kept

clean to prevent excessive pressure drop in the

lines. The dry element of the Spencer filter may be

cleaned with soap & water and reused.

Silencers and Combination Filter-Silencers

Spencer offers silencers and combination filter-

silencers for intake discharge, and bleed applications.

The silencers should be properly supported at both

ends. Rigid connection to the machine is not

recommended. The tubing mount is recommended

and connects to the machine with a rubber sleeve

and a flange to tubing adapter.

This diagram shows the available discharge

positions, viewed from the intake end, and the

direction of blower rotation associated with each

discharge position.

Coupling Alignment

The coupling on this machine was carefully aligned

at the factory and the coupling halves and shell(s)

marked to indicate optimum relative position.

However, transportation may have caused coupling

misalignment.

Caution: Check the motor and blower shafts for

misalignment and carefully realign them if

necessary after Installation and before startup,

as misalignment can cause destructive vibration.

Coupling alignment should be rechecked again

after an hour's operation. Final alignment should

be made at average operating temperature. After

each alignment check, add lubricant per

instructions and replace coupling guard.

WARNING: DISCONNECT AND LOCK OUT

ELECTRICAL POWER BEFORE PERFORMING

ALIGNMENT.

On certain blowers, the coupling is disassembled after

factory alignment and marking. The coupling halves

are specially protected against the elements during

shipping. Prior to startup, assemble the coupling,

align keyways using factory markings and lubricate

as instructed.

Rubber Inlet and Outlet Sleeve

Vacuum Applications

When the machine is used for vacuum, the outlet

should discharge outdoors (preferred) or into a room

having ample volume and proper ventilation in order

to permit the air to escape and at the same time

keep the unit at a reasonable temperature. Intake air

must be kept clean through proper filtration methods.

Motor Rotation

The motor must be wired correctly to rotate the

blower in the right direction. A rotation arrow is

located on the blower housing. "Bump" or jog the

start button and observe the direction of rotation of

the motor shaft. This movement must agree with the

rotation arrow. If the rotation is incorrect, the motor

wiring must be changed.