Spencer single-stage scroll blowers, Standard features optional features – Spencer Single-Stage Scroll Blowers User Manual

Page 11

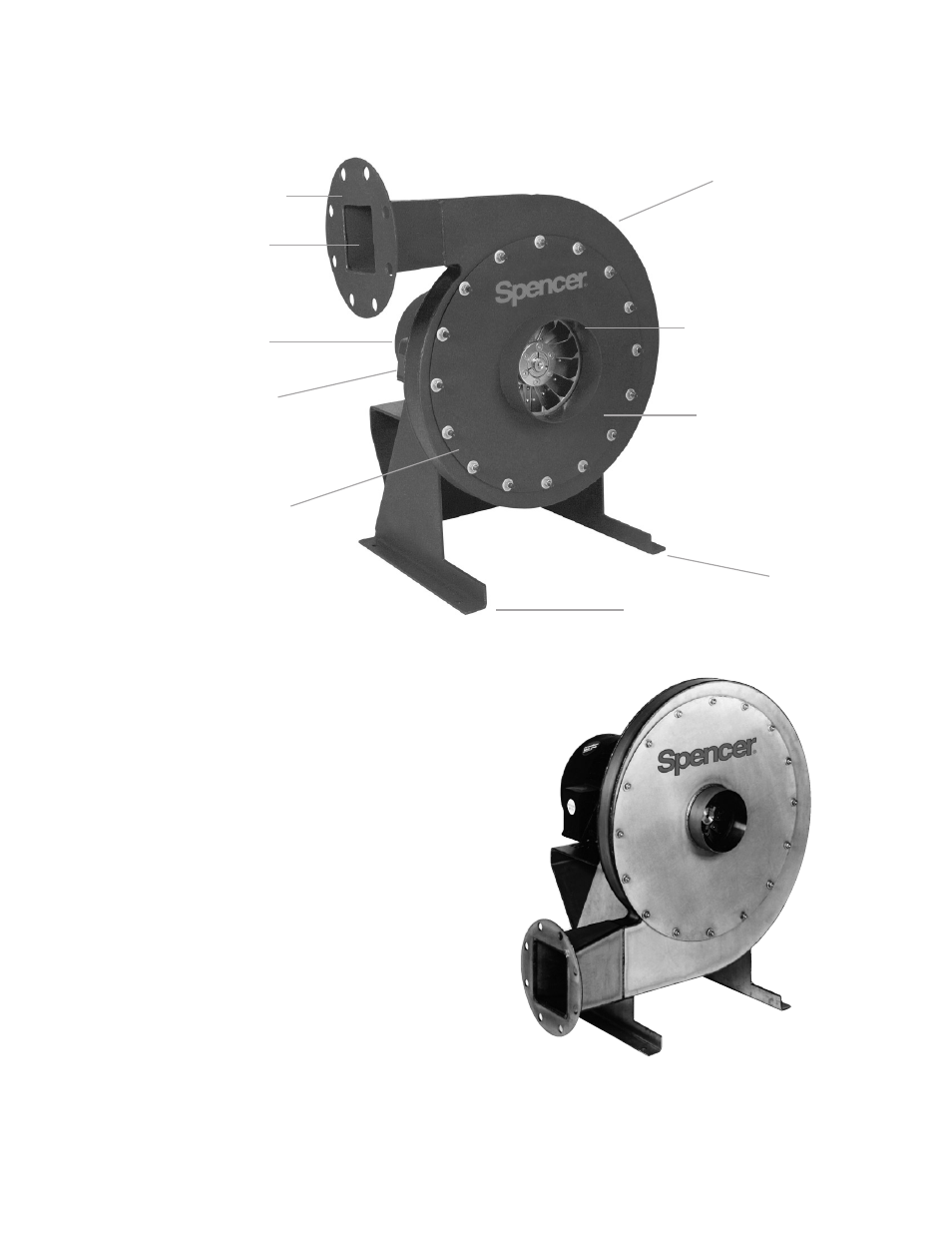

Spencer Single-stage Scroll Blowers

Standard Features

Optional Features

Flanged outlet with standard

ANSI B16.5 125lb/150lb drilling

for ease of installation.

• Stainless steel or other special materials.

• Housing of 1⁄4" or 3⁄8" steel plate.

• Mechanical seal for gas-tight construction.

• Spark-resistant construction.

• High temperature construction with heat slinger.

• Epoxy or other coatings for chemical applications.

• Custom designs.

• Special motor enclosures – chemical duty,

high-efficiency, explosion-proof.

• Casing drains.

• Backward curved impellers to reduce noise and

increase operating stability at low flows.

• Rotatable discharge.

Single-stage scroll blower fabricated from stainless steel.

Heavy-duty 3⁄16" welded steel

housing and motor support.

Heavy-gauge steel absorbs shock

of sudden back pressure.

If damaged, sections can

be repaired or replaced.

Radial bladed aluminum impeller.

Maximum vibration tolerance

1.5 mils total amplitude.

Each impeller is statically

and dynamically balanced

prior to shipment

High efficiency wheel and housing

design results in optimum efficiency

ratings and lower sound levels.

Cork mounting pads.

Blower stands free on cork pads;

no special foundation, bolts or grout required

Six standard outlet positions

provide flexibility of air piping

placement and layout.

Standard shaft motor. ODP or TEFC

motor enclosure is standard.

Direct drive Arrangement No. 4,

with impeller mounted directly

on motor shaft.

Direct drive Arrangement No. 8 or

belt drive Arrangement No. 9 is

available upon request.

Standard finish of epoxy primer

with urethane topcoat

•

Refer to Spencer Bulletin No. TDS192 for Single-stage Scroll Blower specifications.

11

The Spencer Turbine Company ◆ 600 Day Hill Road, Windsor, CT 06095 ◆ TEL 800-232-4321 ◆ 860-688-8361 ◆ www.spencerturbine.com