Gotham DLVI 5cm (2) Adjustable Pinhole SpecSheet User Manual

Page 3

© 2007-2013 Acuity Brands Lighting, Inc. All Rights Reserved. Rev. 07/24/13. Specifications subject to change without notice.

PAGE 3 OF 3

DLVI-2-ADJ-PInhOLE

PH

OTO

M

ET

RY

5cm (2”) DLVI

Adjustable Pinhole

Seamless Cast Faceplate with Open Cone, Max 50 Watt

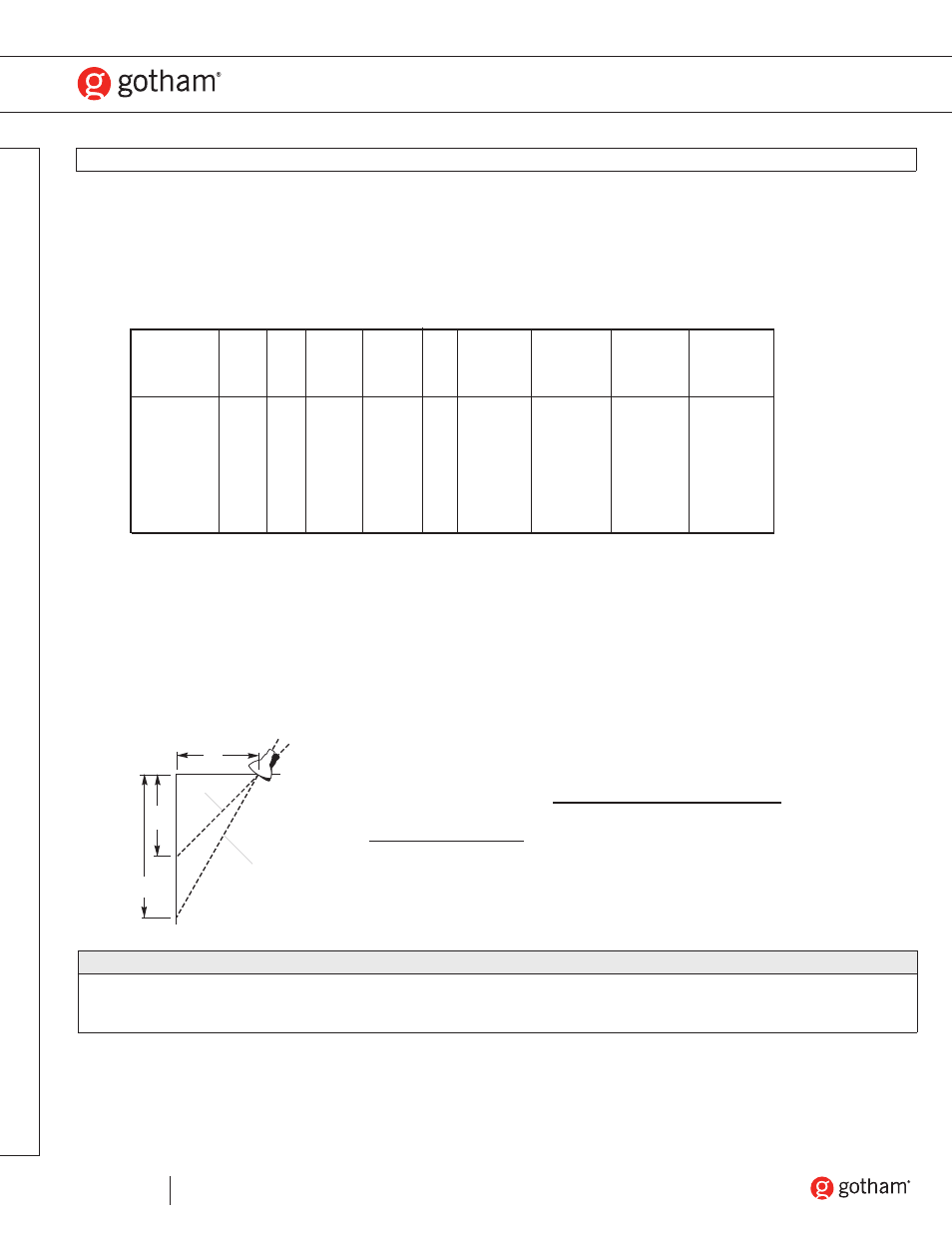

LAMP PERFORMANCE DATA

All data was calculated from each lamp manufacturer’s published data and is subject to normal lamp variations. Maximum footcandle is usually at the aiming point, but not

always on wider spread lamps. Lamp data supplied by manufacturers is approximate, and individual lamp performance may vary.

ACCENT LIGHTING ANGLE PERFORMANCE DATA

DISTANCE LAMP TO LIGHTED SURFACE

2 FEET

4 FEET

DISTANCE DOWN TO AIMING POINT

V1 (FT) 2

V2 (FT)

7

Beam

Lamp No.

Watts Type

MFG. Width (°) MBCP Aiming Angle Beam

Aiming Angle Beam

to

45°

Length Width

60°

Length Width

50% MBCP FT-CANDLES

FT-CANDLES

MR-16

ESX

20

NSP GE/SY/PH

15

3600

318

1.1

0.7

28

4.4

2.1

BAB

20

FL

GE/SY

40

525

46

3.4

2.1

4

19.3

5.8

EXT

50

NSP GE/SY/PH

13

10200

902

0.9

0.6

80

3.8

1.8

EXZ

50

NFL GE/SY/PH

26

3400

301

2.0

1.3

27

8.8

3.7

EXN

50

FL

GE/SY/PH

40

1850

164

3.4

2.1

14

19.3

5.8

EYJ

71/65

MFL

GE/SY

24

4900

433

1.8

1.2

38

7.9

3.4

EYC

71/65

FL

GE/SY

36

2100

186

2.9

1.8

16

15.2

5.2

V1

V2

H

45˚

aiming

angle

60˚

aiming

angle

fc =

MBCP x Cos

3

(aiming angle)

H

2

(distance from wall squared)

Feet

out from wall (H)

6

7

8

9 10

Aiming

angle Cos

3

Feet

down from ceiling (V)

45° .354

6

7

8

9 10

50° .266

7

8 10 11 12

55° .189

9 10 11 13 14

60° .125

10 12 14 16 17

65° .076

13 15 18 19 21

70° .040

17 19 22 25 28

75° .017

22 26 30 34 37

Formula for other distances and aiming angles.

PHOTOMETRY NOTES

•

Tested to current IES and NEMA standards under stabilized laboratory conditions.

•

Actual performance may differ as a result of end-user environment and application.

•

Consult factory or IES file for microgroove baffle, black cone or other photometric reports.